Group B Water System

Design Guidelines

Design Information for New or Expanding

Group B Water Systems.

DOH 331-467

Revised, September 2018

Group B Water System Design Guidelines (DOH 331-467) Page i

September 2018

Table of Contents

TABLE OF CONTENTS .............................................................................................................................. I

CHAPTER 1 INTRODUCTION ............................................................................................................ 3

1.0 PURPOSE AND SCOPE .............................................................................................................................. 4

1.1 “MUST” VERSUS “SHOULD” ................................................................................................................... 4

1.2 JURISDICTION AND STANDARDS ............................................................................................................. 5

1.3 BASIC DESIGN STANDARDS.................................................................................................................... 6

1.4 PROJECT SUBMITTALS ............................................................................................................................ 7

1.5 REQUIREMENTS FOR A PROFESSIONAL ENGINEER .................................................................................. 8

1.6 OTHER REFERENCED DOCUMENTS AND STANDARDS ............................................................................. 9

1.7 DEPARTMENT OF HEALTH CONTACTS .................................................................................................... 9

CHAPTER 2 BASIC WATER SYSTEM INFORMATION .............................................................. 10

2.0 PUBLIC WATER SYSTEM CLASSIFICATION ........................................................................................... 10

2.1 APPLICABILITY .................................................................................................................................... 13

2.2 PROJECT APPROVAL APPLICATION FORM ............................................................................................ 14

2.3 SERVICE AREA MAP AND LOCATION ................................................................................................... 14

2.4 PUBLIC WATER SYSTEM COORDINATION ACT ..................................................................................... 14

2.5 SATELLITE MANAGEMENT AGENCY .................................................................................................... 15

2.6 DISCLOSURE ON PROPERTY TITLE ........................................................................................................ 15

2.7 PROTECTIVE COVENANTS .................................................................................................................... 16

2.8 WATER USERS’ AGREEMENT ............................................................................................................... 16

2.9 WATER FACILITIES INVENTORY ........................................................................................................... 16

2.10 EASEMENTS ..................................................................................................................................... 16

CHAPTER 3 ESTIMATING WATER DEMANDS ........................................................................... 17

3.0 WATER RIGHTS .................................................................................................................................... 17

3.1 RESIDENTIAL WATER DEMAND ........................................................................................................... 19

3.2 NONRESIDENTIAL WATER DEMAND .................................................................................................... 20

3.3 EXAMPLES ........................................................................................................................................... 22

3.4 FIRE SUPPRESSION ............................................................................................................................... 25

CHAPTER 4 SOURCES OF SUPPLY ................................................................................................ 26

4.0 WELL CONSTRUCTION ......................................................................................................................... 26

4.1 SOURCE WATER QUANTITY ................................................................................................................. 27

4.2 SOURCE WATER QUALITY ................................................................................................................... 29

4.3 SOURCE PROTECTION ........................................................................................................................... 31

4.4 INTERTIES ............................................................................................................................................ 31

CHAPTER 5 WELL PUMP, BLADDER TANKS, AND PUMP HOUSE ....................................... 34

5.0 WELL PUMP ......................................................................................................................................... 34

5.1 PRESSURE TANKS ................................................................................................................................. 43

5.2 PUMP HOUSE DESIGN AND CONSTRUCTION RECOMMENDATIONS ........................................................ 48

5.3 WELL AND PUMP HOUSE DETAILED DRAWINGS AND SPECIFICATIONS ................................................ 48

CHAPTER 6 PIPING DESIGN AND CONSTRUCTION ................................................................. 50

6.0 PIPING MATERIAL ................................................................................................................................ 50

6.1 PIPE BURIAL, BEDDING, AND THRUST BLOCKS .................................................................................... 51

6.2 ISOLATION VALVES, FLUSHING HYDRANTS, AND AIR RELEASE VALVES ............................................ 51

6.3 DISTRIBUTION SYSTEM PIPELINE EASEMENTS ..................................................................................... 52

6.4 PRESSURE AND LEAKAGE TEST ............................................................................................................ 52

6.5 DISINFECTION ...................................................................................................................................... 52

6.6 MICROBIOLOGICAL TESTING ................................................................................................................ 52

6.7 SEPARATION FROM NONPOTABLE PIPING SYSTEMS ............................................................................. 53

Group B Water System Design Guidelines (DOH 331-467) Page ii

September 2018

6.8 SERVICE CONNECTIONS ....................................................................................................................... 53

6.9 INDIVIDUAL PRESSURE REDUCING VALVES ......................................................................................... 54

6.10 DISTRIBUTION SYSTEM DETAIL DRAWINGS AND SPECIFICATIONS .................................................. 54

CHAPTER 7 ATMOSPHERIC STORAGE TANKS ......................................................................... 56

7.0 OPERATING STORAGE VOLUME ........................................................................................................... 56

7.1 EQUALIZING STORAGE VOLUME AND ELEVATION ............................................................................... 57

7.2 STANDBY STORAGE VOLUME .............................................................................................................. 58

7.3 FIRE SUPPRESSION ............................................................................................................................... 58

7.4 DEAD STORAGE VOLUME .................................................................................................................... 59

7.5 TOTAL STORAGE VOLUME ................................................................................................................... 59

7.6 RESERVOIR DESIGN REQUIREMENTS AND CONSIDERATIONS ............................................................... 60

CHAPTER 8 BOOSTER PUMPS ........................................................................................................ 63

8.0 BOOSTER PUMP STATION DETAILED DRAWINGS AND SPECIFICATIONS ............................................... 63

CHAPTER 9 TREATMENT FOR SECONDARY CONTAMINANTS........................................... 65

9.0 SECONDARY TREATMENT DESIGN ....................................................................................................... 65

9.1 COMMON STRATEGIES FOR IRON AND MANGANESE REMOVAL ........................................................... 65

9.2 SECONDARY TREATMENT DETAIL DRAWINGS AND SPECIFICATIONS ................................................... 65

9.3 CONSUMER NOTIFICATION REQUIRED ................................................................................................. 66

9.4 TREATMENT WASTE DISPOSAL ............................................................................................................ 66

CHAPTER 10 FINANCIAL VIABILITY ........................................................................................ 68

10.0 COMPLETING THE FINANCIAL VIABILITY WORKSHEET ................................................................... 68

10.1 DISCLOSURE TO CUSTOMERS .......................................................................................................... 68

10.2 EXPLANATION OF TERMS ................................................................................................................ 69

APPENDICES ............................................................................................................................................. 73

To request this document in another format, call 1-800-525-0127. Deaf or hard of hearing customers,

please call 711 (Washington Relay) or email doh.informatio[email protected]. If in need of translation

services, call 1-800-525-0127.

Group B Water System Design Guidelines (DOH 331-467) Page 3

September 2018

CHAPTER 1 Introduction

The Washington State Department of Health, Office of Drinking Water (DOH) developed these

Group B Water System Design Guidelines. They explain how to design Group B water systems

to ensure safe, adequate, and reliable drinking water for those the water system will serve. They

will also help you prepare a complete Group B Design Workbook, which you must submit for

approval before you start constructing your new or expanding Group B water system.

We recommend you review these guidelines before beginning your Group B water system

design. We organized the chapters by subject matter (basic water system information, estimating

water demand, source of supply, and so forth).

The Appendices contain helpful references, such as how to perform and report the results of a

well pump test, using special well pump controls, an outline for a water users’ agreement, and

how to complete an inventory of your proposed water system.

Group B information is available on our website at

doh.wa.gov/CommunityandEnvironment/DrinkingWater/WaterSystemAssistance/GroupB.

Group B Design Workbook

These guidelines will help you prepare a complete Group B Design Workbook (DOH 331-468)

that meets each applicable requirement of chapter 246-291 WAC in an efficient manner that

reflects sound water system design practices and public health principles. You will submit the

workbook to the reviewing authority for approval. You can view, download, or order a CD of the

workbook from DOH at http://doh.wa.gov/odwpubs/.

Make copies of all plans, design drawings, worksheets, equipment information, operations and

maintenance manuals, legal documents, and forms before you send your completed workbook to

the reviewing agency. Keep this information with your other project documents. It will help you

and others manage and operate the new water system successfully. Keep your copy of these

guidelines; do not submit them with your workbook.

Online Group B Resources

We developed the following Group B resources to help you from pre-approval of your water

system design through operation and maintenance.

• All the forms you need to meet the submittal requirements for a new or expanding

Group B water system.

• Guidance to help you operate and maintain your small system. We urge you to

review this information before you begin operating your new or expanded system.

They are online at

doh.wa.gov/CommunityandEnvironment/DrinkingWater/WaterSystemAssistance/GroupB/Resources.

Group B Water System Design Guidelines (DOH 331-467) Page 4

September 2018

Regulations

Before starting your design, become familiar with Washington’s Group B water system rule

(chapter 246-291 WAC) and the information in these guidelines. The Group B rule is online at

doh.wa.gov/CommunityandEnvironment/DrinkingWater/RegulationandCompliance/Rules.

If you have questions about these guidelines or the State Board of Health rules on Group B

Water Systems (chapter 246-291 WAC), contact the state Department of Health (see Table 1.1)

or your local health jurisdiction (LHJ). Contact information for LHJs is at

doh.wa.gov/AboutUs/PublicHealthSystem/LocalHealthJurisdictions.

1.0 Purpose and Scope

These guidelines will help developers, locally certified designers, and design engineers meet the

approval requirements for a new or expanding Group B public water system by:

• Establishing uniform and simplistic concepts for very small water system designs.

• Meeting the submittal requirements described in chapter 246-291 WAC.

• Helping DOH regional engineers and LHJ reviewers to apply consistent review

procedures.

1.0.1 Expanding Systems

Unless otherwise noted, these guidelines apply to new and expanding systems. For example,

suppose your successfully operating existing Group B water system was approved to serve four

residential connections. To expand the system to serve additional residences, your existing

system must meet all current regulatory requirements, regardless of past approval (chapter 246-

291 WAC). You must prepare a complete workbook for review and approval by the reviewing

authority before expanding your water system.

Designers may use design approaches other than those in these guidelines as long as the alternate

approach does not conflict with chapter 246-291 WAC and they give appropriate justification for

taking an alternate approach.

1.1 “Must” versus “Should”

Throughout these guidelines we use the terms “must,” “will,” “shall,” or “required” when

design practice is sufficiently standardized to permit specific delineation of requirements, or

where safeguarding the public health justifies definitive criteria or action (for example, when a

state statute or rule mandates a requirement). The terms “should” or “recommend” indicate

procedures, criteria, or methods that are not required. You can approach these with some degree

of flexibility. Designers and design engineers need to explain the basis of the altered approach

or, in specific circumstances, why another approach may be more applicable.

Group B Water System Design Guidelines (DOH 331-467) Page 5

September 2018

1.2 Jurisdiction and Standards

Many LHJs assist DOH with at least some Group B drinking water program administration.

Others direct the Group B program within their jurisdictions, including approval of Group B

water system designs. In these guidelines, the term "department" refers to the agency that is

responsible for reviewing and approving a Group B water system design in the particular county.

1.2.1 Reviewing Authority

An LHJ has authority to adopt and implement its own Group B regulations, if they are at least as

stringent as chapter 246-291 WAC. Before beginning your Group B workbook, we strongly

recommend that you contact your LHJ to ask:

1. Is it the LHJ or DOH that is responsible for reviewing and approving the Group B

workbook? If the LHJ is responsible, you must submit the completed Group B workbook

to the LHJ for approval.

2. Does the LHJ implement its own local Group B drinking water program? If so, ask

for a copy of their rules and design standards. They could specify available design

options, who can prepare the design, and the available regulatory waivers.

3. Does the LHJ regulate one- or two-connection Group B systems? (Ask if you intend

to construct a one- or two-connection Group B water system).

We based statements in these guidelines on the requirements and limitations in chapter 246-291

WAC. Your LHJ may adopt its own regulations or enter into a Joint Plan of Responsibility with

DOH that offer broader design options, allow for certain waivers, or impose increased regulation

(WAC 246-291-030 (1)(a)). Moreover, if your LHJ implements its own local Group B drinking

water program it may develop its own accompanying design guidelines and Group B design

workbook.

1.2.2 Project Location

The location of your project affects whether you can create a new Group B water system and the

standards that apply to its design and approval. Before beginning your Group B design, we

strongly recommend that you ask the reviewing authority whether the location of your

proposed Group B water system is in:

1. An area the Department of Ecology has closed or established limits to all future

appropriation of groundwater, including gallon per day limits on small

groundwater withdrawals that are normally exempt from the water right permitting

process. If so, this could significantly affect the feasibility, scope, cost, and timing of

your project.

2. A critical water supply service area, as established under the Public Water System

Coordination Act of 1977. If so, you must request service from the existing water utility

serving the area of your proposed Group B water system.

3. An area served by one or more Satellite Management Agency (SMA). If so, an

available SMA must own, or manage and operate your proposed Group B water system

before DOH can approve the water system.

4. A tribal reservation. If so, contact the local health jurisdiction and the tribe for guidance

on approval requirements. DOH has no authority to approve Group B water systems

located entirely within a tribal reservation.

Group B Water System Design Guidelines (DOH 331-467) Page 6

September 2018

1.3 Basic Design Standards

The following standards apply to DOH approval of a Group B water system workbook under

chapter 246-291 WAC. If your LHJ implements its own local Group B drinking water program it

may have its own accompanying design guidelines and Group B design workbook. (WAC 246-

291-030 (1)(a)). Ask your LHJ whether it adopted a set of regulations that affect the standards

for design approval.

1. No supply source will be approved other than a drilled well that meets the requirements

of chapter 173-160 WAC, or an agency-approved intertie with an approved Group A or

Group B water system (WAC 246-291-125). New or expanding Group B systems cannot

use a lake, river, spring, dug well, groundwater under the direct influence of surface

water (GWI), rainfall catchment, or seawater source (WAC 246-291-125).

2. No supply source for a new or expanding Group B water system that exceeds a primary

drinking water standard (such as nitrate, arsenic, coliform) will be approved (WAC 246-

291-125(1) and -170(5)).

3. An LHJ or DOH must inspect the location (“well site”) of any existing or proposed well.

You must submit the inspector’s written well site inspection report with the water system

workbook (WAC 246-291-125(3)).

4. Applicants for a new or expanding water system must receive written approval of the

workbook from the reviewing authority before starting any construction (WAC 246-291-

120(1)).

5. Unless the proposal meets the exemption criteria for an engineer, new and expanding

Group B water systems must be designed by a professional engineer licensed in

Washington State (WAC 246-291-120(3) and (4)). Throughout these Guidelines, we cite

“may require a professional engineer,” in recognition of the exemption criteria. Designers

should note that a professional engineer must prepare and submit the workbook

whenever DOH is the reviewing authority (WAC 246-291-120(3) and (4)).

6. New or expanding water systems designed and intended to serve 10 or more dwelling

units must follow the Group A public water system approval process (WAC 246-291-

200(2)).

7. The design must demonstrate source capacity of at least 750 gallons per day per dwelling

unit for systems located west of the Cascade Mountain crest, and 1,250 gallons per day

per dwelling unit east of the Cascade Mountain crest (WAC 246-291-125(4)).

8. If an SMA is available in the location of a new Group B water system, then the workbook

must document that an SMA will either own or manage and operate the water system

(WAC 246-291-090). This requirement does not apply to an existing Group B water

system seeking to expand its number of approved connections.

9. If a proposed Group B water system is in a Critical Water Supply Service Area, then the

workbook must show that you requested water service from the water utility operating in

the area of the proposed system (WAC 246-291-090). This requirement does not apply

to an existing Group B water system seeking to expand its number of approved

connections if the new connections are in the Group B’s existing service area.

10. Conducting a well-site inspection and undertaking review of a new or expanding

Group B water system workbook are fee-supported activities. The LHJ or DOH will

charge fees. For DOH review fees, see WAC 246-290-990.

Group B Water System Design Guidelines (DOH 331-467) Page 7

September 2018

1.4 Project Submittals

You must submit a complete Group B workbook to DOH for

written approval before construction begins whenever a new

Group B water system is being developed, and whenever an

existing Group B water system seeks an increase the number

of approved connections (an expanding system) (WAC 246-

291-120(1)).

Construction of a new or expanding water system may be

subject to local permits or approvals, including a local

government finding of physical and potable water availability.

Compliance with DOH requirements does not guarantee full

compliance with local rules. You must also satisfy and follow

local approval process. You can get information about local

approval processes from most county building departments and environmental health programs.

DOH’s review of your water system design will not confer or guarantee any right to a specific

quantity of water. We base our review on your representation of available water quantity. If the

Department of Ecology, a local planning agency, or other authority responsible for determining

water rights and water system adequacy determines that you have use of less water than you

represent, the number of approved connections may be reduced commensurate with the actual

amount of water and your legal right to use it.

If your design submittal meets all applicable requirements, you will receive an approval letter.

The letter will refer to the lot(s) the approved system serves, and include a statement such as:

The department’s approval of your water system design does not confer or guarantee

any right to a specific quantity of water. The approved number of service connections

is based on your representation of available water quantity. If the Washington

Department of Ecology, a local planning agency, or other authority responsible for

determining water rights and water system adequacy determines that you have use of

less water than you represented, the number of approved connections may be reduced

commensurate with the actual amount of water and your legal right to use it.

The designer must verify that construction was completed according to the approved plans and

specifications. The designer or inspecting engineer must complete a Construction Completion

Report and submit it to DOH within 60 days of project completion and before providing water to

the public (WAC 246-291-120(5)). The Construction Completion Report form is online at

doh.wa.gov/CommunityandEnvironment/DrinkingWater/WaterSystemAssistance/GroupB/Design.

If the designer considers significant changes from the approved project plans during

construction, the designer must submit to DOH a description of the changes and justification for

them. We must approve the proposed changes before they are constructed (WAC 246-291-120

(6)). Significant change means:

• The size, number, elevation, depth, material, and/or capacity of water system

components are different from those described in the approved workbook.

• Testing procedures differ from those described in the approved workbook.

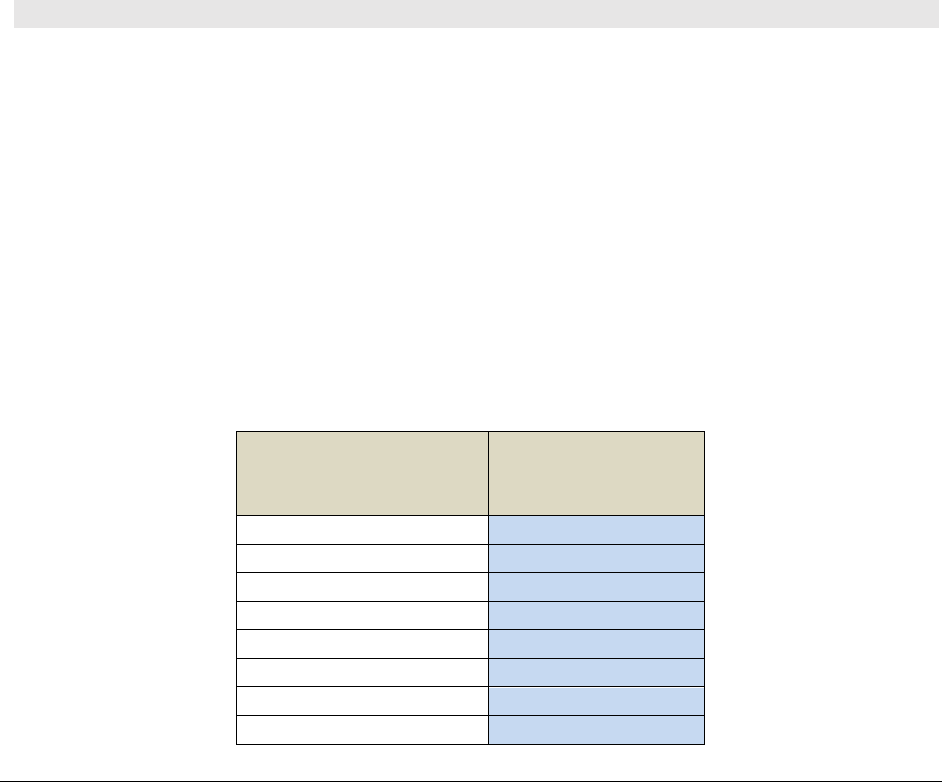

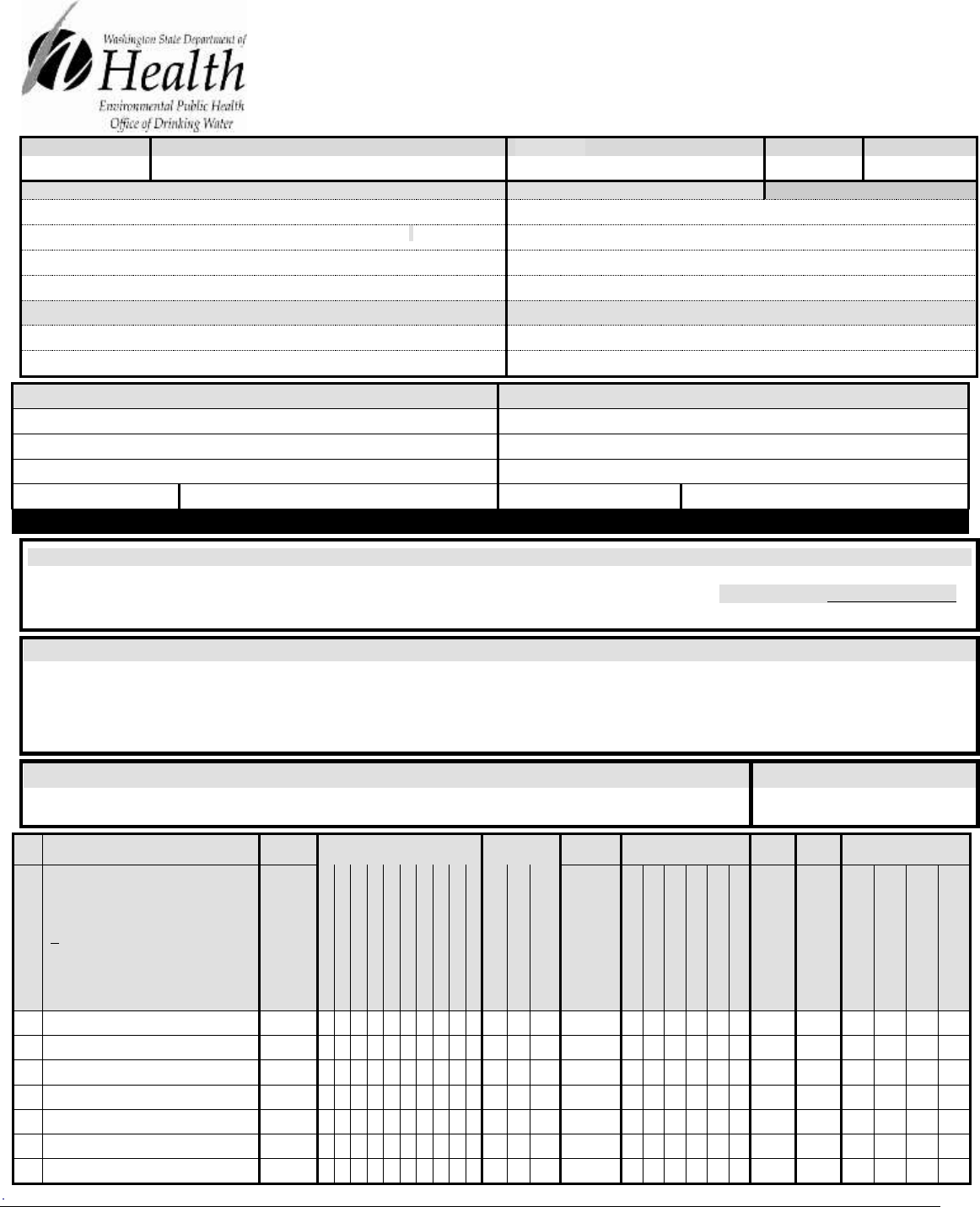

See Figure 1.1 for the project design, submittal, review, and construction process.

Group B Water System Design Guidelines (DOH 331-467) Page 8

September 2018

Figure 1.1: Design, Submittal, Review, and Construction Process

1.5 Requirements for a Professional Engineer

The design report workbook must be prepared by a professional engineer licensed in

Washington State (chapter 18.43 RCW (WAC 246-291-120 (3)). Exceptions to the professional

engineer requirement are only possible when the LHJ has accepted primary responsibility for

review and approval of Group B design report workbooks, and the local Board of Health rules

provide an exception to the professional engineer requirement, and all of the following design

conditions are satisfied:

• No variable speed pumps.

• No fire flow.

• No special hydraulic considerations.

• No atmospheric storage in which the bottom elevation of the storage reservoir is below

the ground surface.

• No more than nine service connections to be served.

Group B Water System Design Guidelines (DOH 331-467) Page 9

September 2018

1.6 Other Referenced Documents and Standards

We cite other waterworks-related laws, guides, standards, and documents in these guidelines to

provide appropriate references. These references form a part of these guidelines, but it is not our

intent to duplicate them.

All water system designs must comply with locally adopted national model codes, such as the

International Building Code (IBC) and Uniform Plumbing Code (UPC), and conform to other

applicable industry standards and guidance, such as that from the American Water Works

Association (AWWA), American Society of Civil Engineers (ASCE), and the American Public

Works Association (APWA) (WAC 246-291-200(1)).

1.7 Department of Health Contacts

The designer or design engineer should contact us with questions or design concerns. DOH

contact information is in Table 1.1. You can get contact information for your LHJ from your

local information sources or online at

doh.wa.gov/CommunityandEnvironment/DrinkingWater/OfficesandStaff.

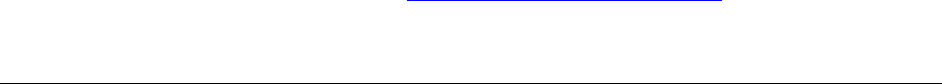

Table 1.1

Office of Drinking Water Regional Offices

Eastern Region

Serving

Drinking Water Eastern Regional Office

16201 E. Indiana Ave., Suite 1500

Spokane Valley, WA 99216

Phone: 509-329-2100

Fax: 509-329-2104

TDD Relay: 1-800-833-6388

Adams, Asotin, Benton, Chelan, Columbia,

Douglas, Franklin, Ferry, Garfield, Grant,

Kittitas, Klickitat, Lincoln, Okanogan, Pend

Oreille, Spokane, Stevens, Walla Walla,

Whitman, and Yakima counties.

Northwest Region

Serving

Drinking Water Northwest Regional Office

PO Box 47800

Olympia WA 98504

Phone: 253-395-6750

Fax: 253-395-6760

TDD Relay: 1-800-833-6388

Island, King, Pierce, San Juan, Skagit,

Snohomish, and Whatcom counties.

Southwest Region

Serving

Drinking Water Southwest Regional Office

Physical: 243 Israel Road

Tumwater, WA 98501

Mailing: P O Box 47823

Olympia, WA 98504-7823

Phone: 360-236-3030

Fax: 360-664-8058

TDD Relay: 1-800-833-6388

Clallam, Clark, Cowlitz, Grays Harbor,

Jefferson, Kitsap, Lewis, Mason, Pacific,

Skamania, Thurston, and Wahkiakum counties.

Group B Water System Design Guidelines (DOH 331-467) Page 10

September 2018

CHAPTER 2 Basic Water System Information

Chapter 2 covers the basic water system information required for most submittals. This includes

the location, size, system classification, and future ownership and management of the water

system.

2.0 Public Water System Classification

Different types of water systems are subject to different regulations. Start by establishing

whether your proposed water system is a public water system. Next, determine the system

classification.

A public water system is any system providing water for human consumption, excluding a

system serving only one single-family residence, or a system with four or fewer service

connections, all of which serve residences on the same farm. See the complete definition in

WAC 246-291-010.

We base public water system classification on population and number of connections

served. There are two classifications: Group A and Group B.

• Group A water systems serve 15 or more connections, OR 25 or more people per day

for 60 or more days within a calendar year.

• Group B water systems serve fewer than 15 service connections and

o Fewer than 25 people per day, OR

o Twenty-five or more people per day for fewer than 60 days per year provided the

system doesn’t serve 1,000 or more people for two consecutive days (WAC 246-

291-005).

These guidelines cover the design standards applicable to Group B public water systems.

2.0.1 Connections Served

Determine the total number of connections by counting each single-family home, each dwelling

unit in a multifamily building, and each nonresidential building that the water system serves. The

complete definition of “service connection” is in WAC 246-291-010.

For the purposes of assessing the number of connections associated with a Group B design, an

Accessory Dwelling Unit (ADU) is considered a separate dwelling unit if it is located outside

and separate from the single family residence. An ADU located within the single-family

residence, such as a mother-in-law apartment in the basement, is not considered a separate

connection.

In the following examples, we applied the definitions of service connection in WAC

246-291-010 and how we count ADUs.

• A system serving two duplexes and two single-family homes serves a total of six

dwelling units. Each dwelling unit is considered a separate connection.

• A system serving four single-family homes, each with an accessory dwelling unit

incorporated into the main structure of the home, serves a total of four dwelling units, and

therefore four connections.

Group B Water System Design Guidelines (DOH 331-467) Page 11

September 2018

• A system serving four single-family homes, each with an accessory dwelling unit built as

a separate structure on the same parcel, serves a total of eight dwelling units and,

therefore, eight connections.

• A system serves three single-family homes. One home has an attached shop with piped

water that serves as a place of employment for people from outside the home. The other

two homes each have a separate structure with piped water that serves as a retail or

commercial business open to customers or clients. This system serves three dwelling

units plus three nonresidential connections, for a total of six connections.

DOH will not recognize ADUs an applicant claims as a dwelling unit unless:

• The proposal assumes ADUs on each lot served.

• Zoning permits the construction of separate-structure ADUs on each lot served.

• The property title for each lot discloses the water system is designed to supply a

separate-structure ADU on each lot. See Section 2.6.

Section 2.0 of the design workbook explains how to report the number of residential and

nonresidential connections your Group B water system will serve.

2.0.2 Population Served

The population you must count is the number of people that have access to piped water for

human consumption. The population served is either residential (people living in a residence), or

nonresidential (tourists, customers, employees) entering the premises and given the opportunity

to access tap water. Here are two examples of estimating population based on access.

A Post Office has a restroom and coffee bar or sink located behind the customer counter,

where only employees can access these facilities. There is no water service provided in

the visitor or customer service area of the Post Office. The number of people served by

this water system is the number of people who work at the Post Office. Do not count

visitors.

A commercial business has a rest room accessible to the public. The estimated service

population should be based on the estimated number of customers plus employees. Count

everyone expected to enter the business.

2.0.2.1 Residential Population

For the purposes of design, and to identify the appropriate water system approval standards,

2.5 residents must be assigned to each dwelling unit (WAC 246-291-200(2)). Local health

jurisdictions cannot waive or modify this population standard. Therefore, if your

proposed system serves 10 or more dwelling units, we will review your proposal under the

approval standards for Group A public water systems (chapter 246-290 WAC). Group A

system approval standards are different from Group B system approval standards. See

Section 2.0.3 below.

2.0.2.2 Nonresidential Population

A water system designed to serve 25 or more people for 60 or more days per year will be

considered a Group A water system (WAC 246-290-005). Our data system uses the

information you provide on your Water Facilities Inventory Form (WFI) to calculate a daily

Group B Water System Design Guidelines (DOH 331-467) Page 12

September 2018

average for each calendar month. (See Section 2.9.) If your expected average daily service

population for two or more calendar months exceeds 24 people, we will review your proposal

under the approval standards for Group A public water systems. See Section 2.0.3 below.

2.0.3 Application of Group A Public Water System Approval Standards

If we conclude that the scope of your project places your proposed water system into the Group

A classification, we will return your Group B workbook to you with an explanation. Contact

your DOH regional office to discuss the conclusion and, as applicable to your circumstance, the

Group A public water system approval process.

2.0.4 Applying Under False Pretense

We are aware of the incentive for applicants to submit false or misleading information

intentionally presenting an application for a Group A water system when the intended

development actually meets the definition of a Group B water system. For example:

An applicant plans a four-lot subdivision to be served by a new Group B water

system. The Department of Health is the approving authority in this jurisdiction.

Before submitting the Group B design for approval, the applicant drills and tests a

new well. The well produces a sufficient supply but exceeds the arsenic standard.

The Group B rule prohibits DOH from approving the source (chapter 246-291

WAC). The Group A rule does not prohibit DOH from approving this source if

arsenic treatment is designed and installed (chapter 246-290 WAC).

To create a pathway for project approval, the applicant claims the water system

will serve a fictitious commercial connection in addition to the four residences,

thus pushing the population above 24 people served at least 60 days per year. The

applicant claims the design is for a Group A water system.

Because the commercial connection never occurs, the system never becomes a Group A water

system and, therefore, the treatment process is never subject to any oversight. To protect public

health for the life of the water system, the state Board of Health adopted a rule allowing

treatment only if the approving authority grants a waiver (chapter 246-291 WAC). The

approving authority must have the resources and authority to oversee the treatment process to

ensure proper treatment for the life of the water system.

To prevent applicants from bypassing the rule by pretending to propose Group A systems, DOH

will require any applicant who claims a Group A commercial use associated with a Group B

residential development to submit detailed supporting documentation if a source exceeds a

primary drinking water quality standard.

Group B Water System Design Guidelines (DOH 331-467) Page 13

September 2018

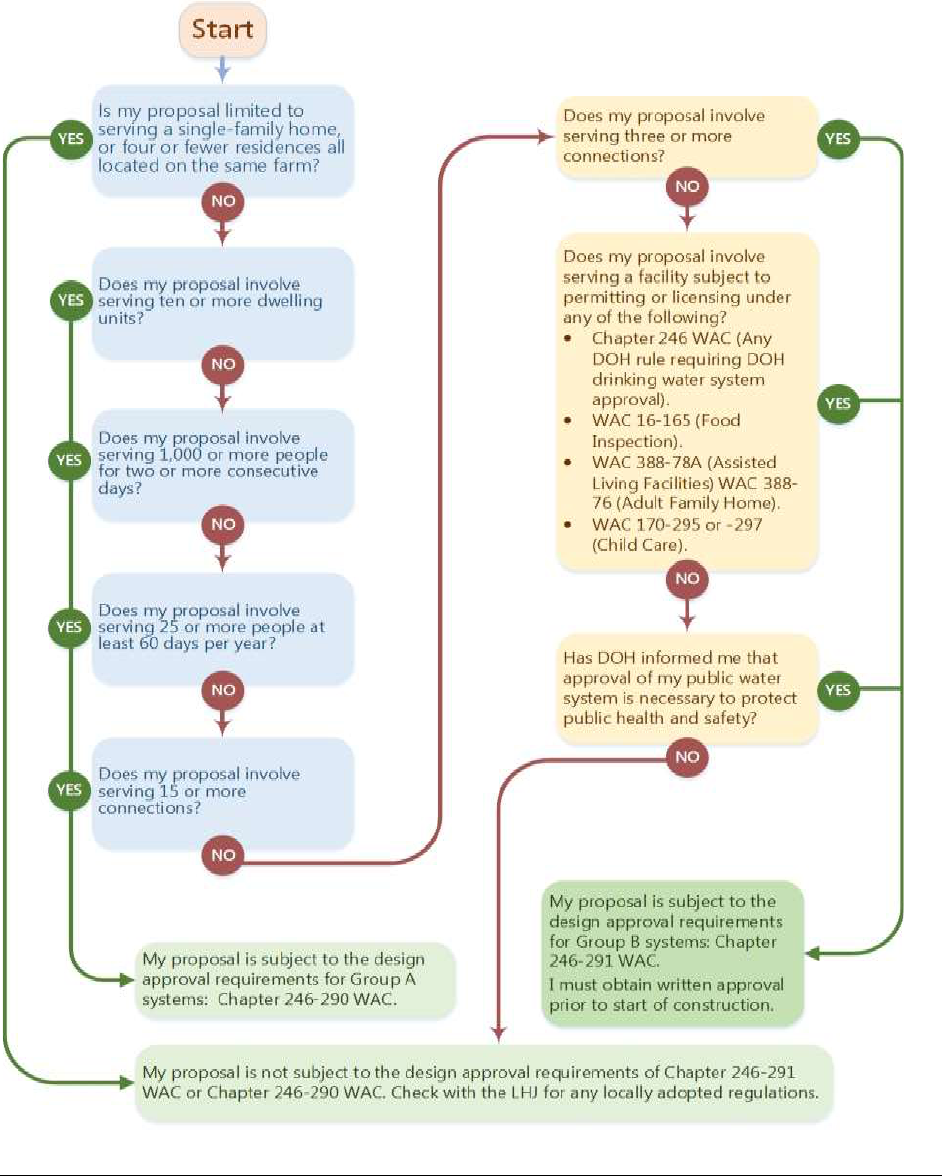

2.1 Applicability

Based on public water system definitions and classifications (see Section 2.0), the following flow

chart will help you decide whether your proposed Group B public water system is subject to the

Group B design approval process. Please note that DOH is responsible for properly classifying

public water systems. Your use of this flow chart does not replace our responsibility.

Group B Water System Design Guidelines (DOH 331-467) Page 14

September 2018

2.2 Project Approval Application Form

On the Group B Project Approval Application Form, the designer provides the information

necessary to review and process the application properly. This information includes:

• Contact information for both the water system and the person submitting the

project.

• The number and type of connections the system serves or will serve.

• The type of project.

The Group B Project Approval Application Form is online at

doh.wa.gov/CommunityandEnvironment/DrinkingWater/WaterSystemAssistance/GroupB/Design.

2.3 Service Area Map and Location

Applicants for a new or expanding water system must also provide a scaled map of the proposed

service area (WAC 246-291-140(1)). You can use the same map submitted with a land use

application or one that is similarly detailed. The map you use should include the boundaries of

the proposed service area, roads, property lines, parcel numbers, and other features helpful in

locating the project and individual features. You can use the same map to show the proposed

distribution system, or use a separate map.

2.4 Public Water System Coordination Act

The Public Water System Coordination Act of 1977 (RCW 70.116) requires applicants seeking

development of a new public water system to determine whether the proposed system is in the

future service area of an existing utility. The intent of the Coordination Act is to avoid creating

new water systems whenever an existing water system is available and willing to provide

service.

If your project is in a Public Water System Coordination Act planning area, ask the

reviewing authority to identify the utility providing service. You must request water service

from that utility. If the utility can provide service in a timely and reasonable manner, you must

obtain water service from the utility and abandon plans to develop a new water system (WAC

246-291-090). This requirement does not apply to an existing Group B water system seeking to

expand its number of approved connections if the new connections are in the Group B’s existing

service area.

To ensure compliance with this statute, you must include a written record of the request for

water service and the water supplier’s written response to that request in your workbook

(WAC 246-291-120). An example of a letter requesting water service is in the Appendix A.

If your project is outside a Public Water System Coordination Act planning area, you may

develop a new water system. However, your application is subject to the Satellite Management

Agency requirement (WAC 246-291-090).

Group B Water System Design Guidelines (DOH 331-467) Page 15

September 2018

2.5 Satellite Management Agency

A Satellite Management Agency (SMA) is an individual, water system, or other entity approved

by DOH to own or operate public water systems on a regional or countywide basis. The law

requires an approved SMA to own or operate all new water systems if one is available (RCW

70.119A.060). The intent of the SMA requirement is to place ownership, or operations and

management, of all new public water systems in the hands of experienced water suppliers

whenever possible. This requirement does not apply to an existing Group B water system

seeking to expand its number of approved connections.

All counties have at least one approved SMA. You should choose the SMA that best meets your

needs. The current approved SMA list is online at

doh.wa.gov/Portals/1/Documents/4200/sma_list.pdf.

If your project is in the service area of one or more approved SMA, ask each one whether it is

available to provide ownership or management services to your proposed public water system.

An example of a letter requesting SMA services is in Appendix B.

You must either provide a copy of an SMA agreement with your project submittal or proof that

no approved SMA is available (WAC 246-291-090 and -120).

YES, an SMA is available to own the proposed water system or provide management

services. You must provide a copy of the agreement with the project submittal.

NO SMA is available. You must provide a written record of each SMA rejection with

your project submittal.

Your SMA may require you to submit to them your water system design for review and

acceptance before you submit your application to DOH for approval, particularly if the SMA will

become the owner of the new water system.

SMA operational and management services may include:

• Creating and updating standard operating procedure and routine maintenance procedures.

• Reviewing and updating water system governance documents, including policies.

• Input on capital investment and infrastructure planning.

• Budgeting assistance and billing services.

• Sampling and treatment plant (if any) data collection and evaluation.

• Periodic inspection of sanitary control area, reservoir, and other infrastructure.

• Input on water main break, pump, and power failure response protocols.

• Response to complaints, water outages, and water quality emergencies.

Please review our publication Choosing a Satellite Management Agency (DOH 331-604).

2.6 Disclosure on Property Title

You must record an informational notice on the title of each property your new water system

will serve (WAC 246-291-140(2)). A sample notice is in Appendix C. When submitting your

workbook to the reviewing authority, provide a copy of the content you will record on the title of

each property your water system will serve. List all parcel numbers available at the time you

submit your completed Group B design workbook. The actual recorded document must include

the actual parcel numbers the water system will serve.

Group B Water System Design Guidelines (DOH 331-467) Page 16

September 2018

Ask your County Auditor which form you should use to record notice to title.

2.7 Protective Covenants

Protective covenants are required to secure the area around a public drinking water supply from

future use and development that may threaten water quality and public health (WAC 246-291-

125(5)). Section 4.3 explains how to provide legal protection for the area around a public

drinking water supply well. When submitting your workbook to the reviewing authority, provide

a copy of the actual protective covenants on record with the County Auditor for each public

drinking water supply well.

These covenants must be on each of the affected properties, and filed with the County Auditor.

Check with your local government; you may be allowed to establish the covenant on the

subdivision plat.

Ask your County Auditor which format you should use to record the protective covenants for

each public drinking water supply well.

2.8 Water Users’ Agreement

You should establish a water users’ agreement for all new Group B water systems that include

residences or multiple property owners. All owners of the water system should sign the users’

agreement when the system is constructed and operational. An outline for a water users’

agreement is in Appendix D.

You may need to complete your water system design before you can finalize your draft water

users’ agreement.

2.9 Water Facilities Inventory

We recommend that you complete a Water Facilities Inventory Form (WFI) and include it with

your Group B workbook. To ensure the information in our data system is correct, answer all the

questions on the WFI. Instructions for Group B systems and a sample WFI form are in

Appendix E. If you plan to submit a workbook for an expanding Group B system, please submit

a marked-up version of your existing WFI form.

2.10 Easements

Your Group B workbook must show the location and dimension of easements you intend to

secure in order to adequately access and maintain all distribution system components, reservoirs,

wells, and pumping stations (WAC 246-291-120).

Group B Water System Design Guidelines (DOH 331-467) Page 17

September 2018

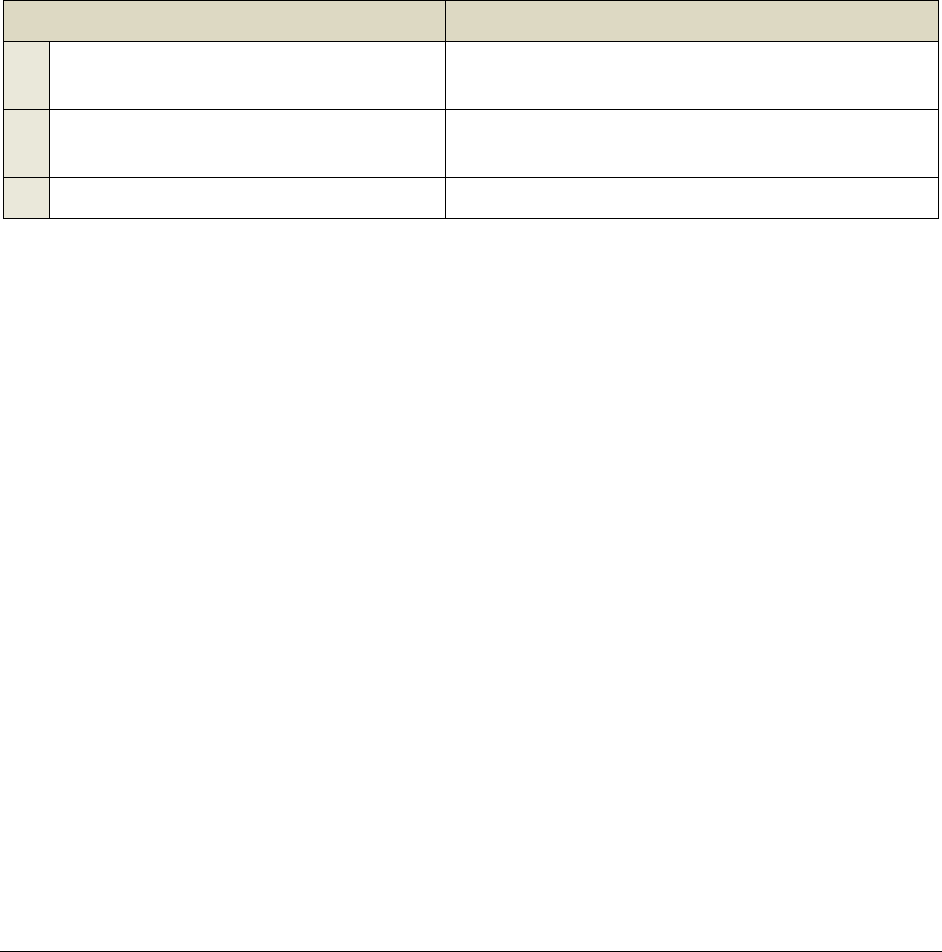

CHAPTER 3 Estimating Water Demands

Chapter 3 explains how to estimate expected Maximum Daily Demand (MDD) and Peak Hour

Demand (PHD) for your proposed water system. Engineers need water demand estimates to size

pumping equipment, transmission lines, distribution mains, and water storage facilities properly.

Demand estimates combined with information about your water supply source ensures the water

system can meet all the demands you expect it to meet over the year. Establishing the expected

MDD also determines whether you need a water right (RCW 90.44.050).

If you do need a water right, you must get the appropriate documents from the Department of

Ecology and include them in your workbook (WAC 246-291-125(3)).

If we believe you need a water right, but you don’t provide a copy with your submittal, we will

return your submittal to you. We will also explain our decision and recommend that you consult

with Ecology before resubmitting your design.

3.0 Water Rights

3.0.1 Water Right Permit Exempt Wells

The Department of Ecology administers the regulatory and permitting processes for water rights.

Newly designed Group B water systems may only obtain water from a groundwater source. Most

Group B water systems use the groundwater permit exemption (RCW 90.44.050) rather than

obtaining a permit from Ecology prior to using any water. There are different limitations on the

use of single domestic permit-exempt wells and group domestic permit-exempt wells.

Depending on the watershed, the owner of a group domestic permit-exempt well may withdraw

up to 5,000 gallons per day for group domestic uses. In addition, the owner may have a separate

allowance to irrigate lawns or noncommercial gardens. This separate irrigation allowance under

a group domestic permit-exempt well is not limited in terms of gallons per day; it is limited in

area. In addition to the 5,000 gallons per day limit for domestic use, the owner of a permit-

exempt well may withdraw any amount of water for irrigation not to exceed a combined total of

½ acre of lawns and noncommercial gardens, so long as the water is put to beneficial use.

Depending on the watershed, the owner of a single domestic well may have a specified

maximum daily withdrawal allowance different from the group domestic permit exemption. This

limitation may include all uses from the single domestic well, including irrigation.

For a complete description of the legal uses of a permit-exempt well, consult with Ecology about

water availability or visit

www.ecology.wa.gov/Water-Shorelines/Water-supply/Streamflow-restoration.

Permit-exempt wells are exempt only from the duty to obtain a permit to use groundwater, not

the other provisions of the Water Code. A right established through a permit-exempt well has the

same legal effect and must abide by the same requirements of prior appropriation and state

regulation of water resources as a permitted withdrawal. In other words, use of water from a

permit-exempt well must be regulated or curtailed, where necessary, to protect and prevent

impairment to more senior water rights. Even if your Group B water supply is a permit-exempt

Group B Water System Design Guidelines (DOH 331-467) Page 18

September 2018

well, it’s subject to curtailment if Ecology finds such action necessary to protect senior rights or

public waters. Local government must ensure an adequate potable water supply before issuing a

building permit. Before developing a permit exempt well check with local authorities on their

criteria for establishing an adequate potable water supply for your planned water system.

When assessing the need for a water right, you should assume that the domestic in-home

portion of your total system maximum daily demand (MDD) will be at least 350 gallons per

day (gpd) per dwelling unit. The domestic in-home demand is the portion of the total system

MDD that counts toward the 5,000-gallon-per-day limit described above.

3.0.2 Basins Closed to Further Appropriation

Ecology may close a basin to all further appropriation or establish reservations of water for

permit-exempt wells to protect senior water right holders and minimum instream values.

However, Ecology may create a pathway for an applicant of a new Group B water system to

follow a basin-specific process to secure permission to withdraw groundwater to supply the

system.

A basin-specific process may involve developing and implementing a mitigation plan. To

determine whether your project is located in a closed basin, contact Ecology. If so, you must

submit Ecology’s written permission to withdraw the groundwater you need with your Group B

water system workbook. While such permission, if granted, is not a “water right,” we apply the

requirement of WAC 246-291-125 (3) to such circumstances.

3.0.3 Multiple Permit-Exempt Withdrawals

The rule permits only one exemption for any one project, no matter how many wells and separate

small systems are established to supply the project.

If you intend to develop two or more separate, contiguous Group B water systems, you may not

have the legal authority to do so. Contact Ecology for assistance on this legal requirement.

3.0.4 Group B Applicants with a Water Right

A water right may state the number of connections that can be served. With one exception (see

below), the number of connections shown on the water right is a limiting factor for a new or

expanding system intended to serve fewer than 15 residential connections. In other words, if the

water right specifies that it applies to serving six single family homes, then the maximum

number of homes that can be served by the water system is six, even if the instantaneous and

annual volume permitted under the right could supply more homes.

The one exception is when an existing municipal water supplier owns the new or expanding

Group B system. Applicants who want to know whether their organization is a municipal water

supplier should contact their DOH regional office.

Group B Water System Design Guidelines (DOH 331-467) Page 19

September 2018

3.1 Residential Water Demand

3.1.1 Residential MDD

The MDD is the maximum single-day demand the water supply must meet. It consists of in-

home domestic demand (see Section 3.0.1), outdoor demand, nonresidential demand, and

distribution system leakage. It’s important to establish the proposed water system’s MDD before

you drill and test the water supply well.

WAC 246-291-125 (4) specifies the minimum source capacity and minimum MDD for

residential service connections (see Table 3.1).

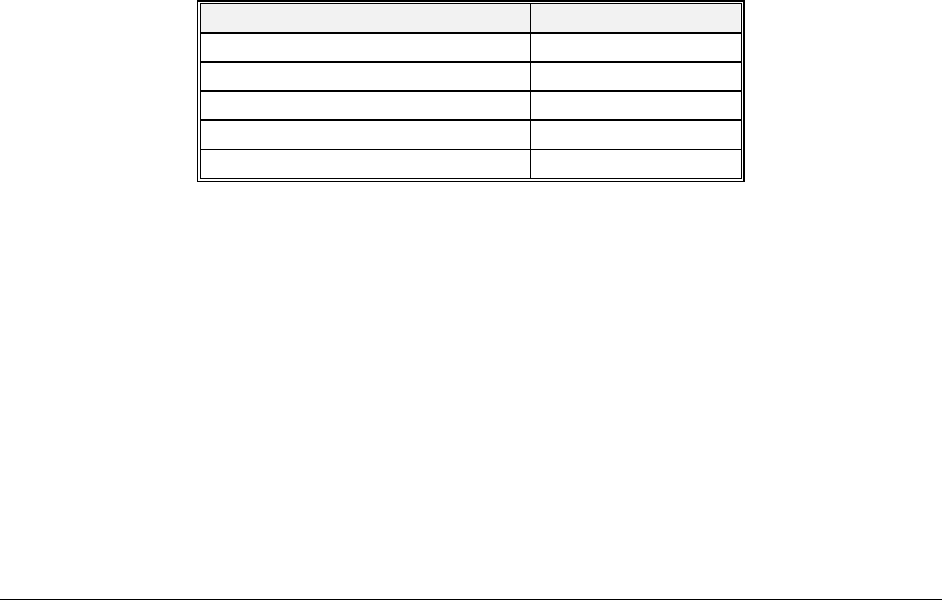

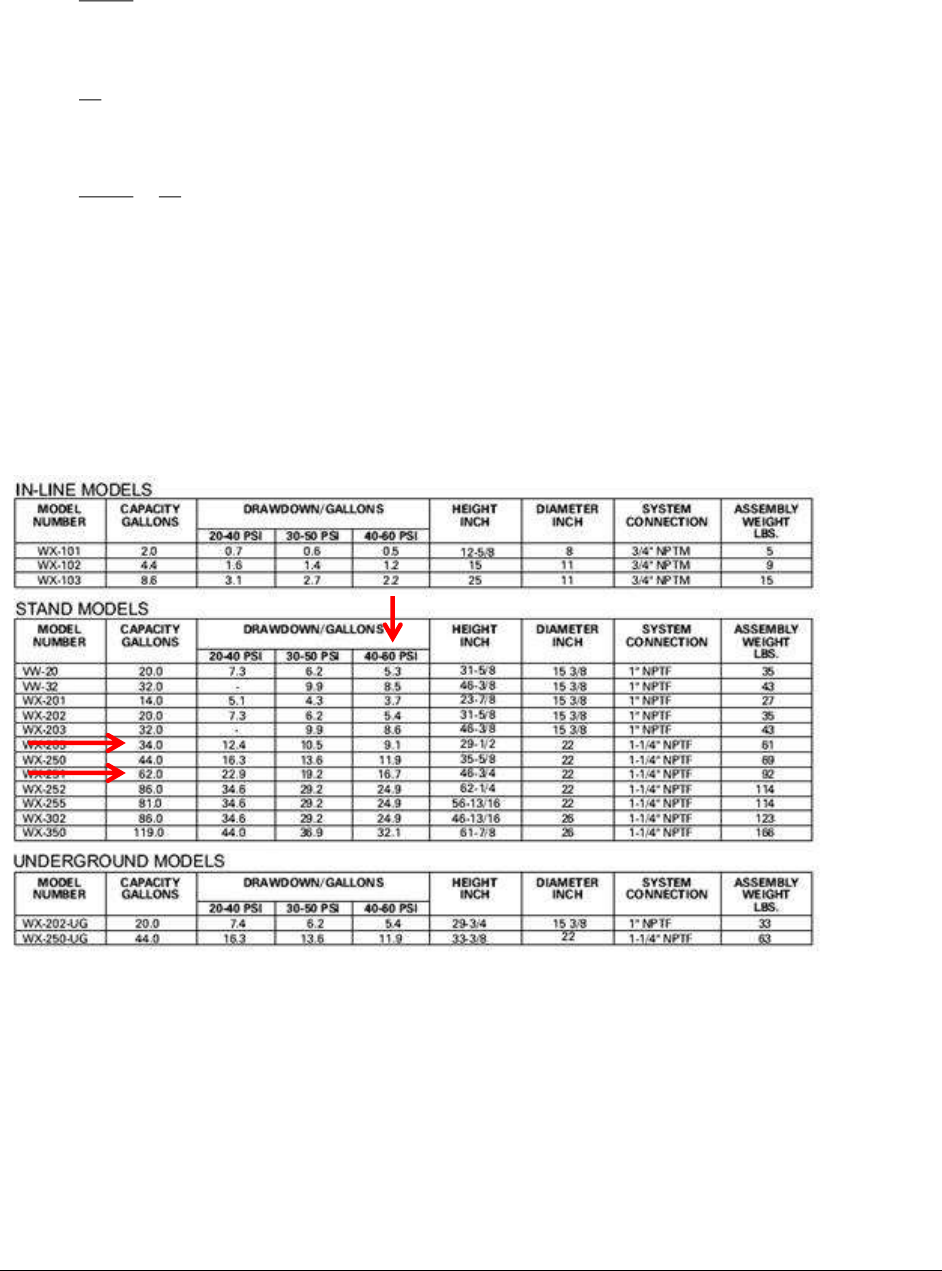

Table 3.1

Standards for Minimum Source Capacity and

Minimum MDD for Residential Service Connections

County

Gallons per day per

dwelling unit

Clallam, Clark, Cowlitz, Grays Harbor, Island, Jefferson, King,

Kitsap, Lewis, Mason, Pacific, Pierce, San Juan, Skamania, Skagit,

Snohomish, Thurston, Wahkiakum, and Whatcom

750

Adams, Asotin, Benton, Chelan, Columbia, Douglas, Ferry,

Franklin, Garfield, Grant, Kittitas, Klickitat, Lincoln, Okanogan,

Pend Oreille, Spokane, Stevens, Walla Walla, Whitman, and

Yakima

1,250

Because residential MDD includes inside and outside uses, the actual demand could be

considerably higher than the minimum values listed in Table 3.1. In general, the demand for

water increases along with lot size, home size, and average summer temperatures. Other site-

specific considerations, such as the development’s Covenant, Conditions, and Restrictions; cost

of water; soil type; and irrigation system technology, may also affect water demand. The

designer and design engineer should strongly consider whether the minimum values in Table 3.1

are sufficient to meet the expected demands of future customers. The effect of under-estimating

the MDD includes low pressure, summertime water rationing, dissatisfied customers, and

increased vulnerability to backsiphonage of nonpotable water into the distribution system.

3.1.2 Residential PHD

It’s important to establish the peak hourly demand (PHD) before designing the system of wells,

pumps, pipes, and pressure tanks. The relationship between PHD, sustained well yield, and well

pump capacity will determine whether the proposed water system requires atmospheric storage

to supplement the supply source(s) to meet the expected PHD. See Chapter 5 for details.

Table 3.2 provides guidance on establishing the minimum PHD for residential demand. For the

same reasons cited in 3.1.1 above, the actual PHD of the customers your proposed Group B

system will serve could be considerably higher than the values in Table 3.2. The effect of under-

estimating the PHD includes low pressure, dissatisfied customers, and increased vulnerability to

backsiphonage of nonpotable water or other potential contaminants into the distribution system.

Group B Water System Design Guidelines (DOH 331-467) Page 20

September 2018

Table 3.2

Guide for Minimum Residential Peak Hourly Demand

Number of

dwelling units

Peak Hour Demand

(in gallons per minute)

2

23

3

26

4

28

5

31

6

34

7

36

8

39

9

41

Source: Adapted from DOH Water System Design

Manual.

3.2 Nonresidential Water Demand

3.2.1 Nonresidential MDD

Table 3.3 provides guidance on nonresidential average maximum daily demand (MDD). We use

the values here as guidance with the following assumptions:

• Unit nonresidential demand will vary little from day to day.

• MDD is based on a full facility (the campsite or hotel is fully occupied or the school is

operating at capacity).

Table 3.3

Guide for Nonresidential Water Demand

Type of Establishment

Maximum Daily

Demand

(in gallons per day)

Bathhouse (per bather)

10

Boardinghouse (per boarder)

Additional kitchen requirements for nonresident boarders

50

10

Camp:

Construction, semi-permanent (per worker)

Day, no meals served (per camper)

Luxury (per camper)

Resort, day and night, limited plumbing (per camper)

Tourist, central bath and toilet facilities (per person)

50

15

100 - 150

50

35

Factory (gallons per person per shift)

15 - 35

Highway rest area (per person)

5

Hotel:

Private baths (2 persons per room)

No private baths (per person)

50

50

Institution other than hospital (per person)

75 - 125

Laundry, self-serviced (gallons per washing (per customer))

50

Motel:

Bath, toilet, and kitchen facilities (per bed space)

Bed and toilet (per bed space)

50

40

Group B Water System Design Guidelines (DOH 331-467) Page 21

September 2018

Type of Establishment

Maximum Daily

Demand

(in gallons per day)

Park:

Overnight, flush toilets (per camper)

Trailer, individual bath units, no sewer connection (per trailer)

Trailer, individual baths, connected to sewer (per person)

25

25

50

Picnic:

Bathhouses, showers, and flush toilets (per picnicker)

Toilet facilities only (gallons per picnicker)

20

10

Restaurant:

Toilet facilities (per patron)

No toilet facilities (per patron)

Bar and cocktail lounge (additional quantity per patron)

7 - 10

2 ½ - 3

2

School:

Day, cafeteria, gymnasiums, and showers (per pupil)

Day, cafeteria, no gymnasiums or showers (per pupil)

Day, no cafeteria, gymnasiums or showers (per pupil)

25

20

15

Service station (per vehicle)

10

Store (per toilet room)

400

Worker:

Construction (per person per shift)

Day (school or offices, per person per shift)

50

15

Sources: Adapted from Design and Construction of Small Water Systems American Water Works

Association, 1984; and Planning for an Individual Water System. American Assoc. for Vocational

Instruction Materials, 1982.

3.2.2 Nonresidential PHD

Tables 3.4 and 3.5 provide guidance on establishing nonresidential PHD.

Table 3.4

Demand Weight in Fixture Units

Fixture Type

Weight in Fixture Units

per Fixture Type

Shower

2

Kitchen sink

1.5

Urinal

3

Toilet (flushometer)

5

Toilet (tank flush)

2.5

Bathroom sink (lavatory)

1

Clothes washer

4.0

Drinking fountain

0.5

Dishwasher

1.5

Hose Bibb

2.5

Source: Adapted from the 2009 Uniform Plumbing Code, Appendix A, Table A-2.

After determining the total number of fixture units (sum of fixture type times fixture weight),

round the total to the next value given in Table 3.5, and determine the peak hourly demand.

Group B Water System Design Guidelines (DOH 331-467) Page 22

September 2018

Table 3.5

Nonresidential Peak Hourly Demand

Based on Total Fixture Units

Total Number of

Fixture Units

PHD (gpm)

10

8

15

12

20

15

25

18

30

20

35

22

40

25

50

29

60

32

70

35

80

38

90

41

100

43

Source: Adapted from the 2009 Uniform Plumbing Code,

Appendix A.

3.3 Examples

Example 3-1

A new Group B water system proposed east of the Cascade Mountains consists of six single-

family homes. The plan for development allows each lot to irrigate up to 3,500 square feet, for a

total irrigated area of 21,000 square feet. The design relies on supply from a group domestic

permit-exempt well. The system will not supply fire-suppression requirements (fire hydrants or

residential sprinkler systems).

Check water right:

✓ Maximum daily residential in-home demand is assumed to be 350 gpd per residence

6 residences x 350 gpd per residence = 2,100 gpd

This is less than the 5,000-gpd limitation on a group domestic permit-exempt well. OKAY

✓ Total irrigated area is below the maximum 21,780 square feet allowed without a water right.

OKAY

Minimum required MDD and water supply capacity = 6 homes x 1,250 gpd/home (per Table 3.1)

= 7,500 gpd

PHD = 34 gpm (per Table 3.2)

Group B Water System Design Guidelines (DOH 331-467) Page 23

September 2018

Example 3-2

A new Group B water system proposed west of the Cascade Mountains consists of four single-

family homes. The plan for development allows each lot to irrigate up to 5,000 square feet, for a

total irrigated area of 20,000 square feet. The design relies on supply from a group domestic

permit-exempt well. The system will not supply fire-suppression requirements (fire hydrants or

residential sprinkler systems).

Check water right:

✓ Maximum daily residential in-home demand is assumed to be 350 gpd per residence

4 residences x 350 gpd per residence = 1,400 gpd.

This is less than the 5,000 limitation on a group domestic permit-exempt well. OKAY

✓ Total irrigated area is below the maximum 21,780 square feet allowed without a water right.

OKAY

Minimum required MDD and water supply capacity = 4 homes x 750 gpd/home (per Table 3.1)

= 3,000 gpd

PHD = 28 gpm (per Table 3.2)

Example 3-3

A new water system proposed east of the Cascade Mountains consists of nine single-family

homes. The planning documents for this development indicate that each lot is 10 acres and each

lot owner will be allowed to irrigate up to 5,000 square feet. The design relies on supply from a

group domestic permit-exempt well. The system will not supply fire-suppression requirements

(fire hydrants or residential sprinkler systems).

Check water right:

✓ Maximum daily residential in-home demand is assumed to be 350 gpd per residence

9 residences x 350 gpd per residence = 3,150 gpd

This is less than the 5,000 limitation on a group domestic permit-exempt well. OKAY

Total irrigated area is 45,000 square feet (9 x 5,000). This exceeds the area allowed without a

water right. NOT OKAY.

We will return the workbook with instruction to change the irrigation allowance, or obtain a

water right.

Example 3-4

An existing Group B water system located west of the Cascade Mountains consists of six single-

family homes. The owner wishes to add five single-family homes to the existing system. We

approved the existing system in 2001.

As described in Section 1.4, the Group B design requirements apply to new and expanding

Group B systems. There is no “grandfathering” of existing system design when the owner of the

Group B Water System Design Guidelines (DOH 331-467) Page 24

September 2018

system proposes an expansion. So, the owner must apply the requirements of the current Group

B Rule to all 11 connections (6 existing and 5 proposed), including such standards as minimum

MDD and demonstrated source capacity per dwelling unit, population per dwelling unit, notice

to title, and limits on irrigation per parcel.

An expanding system proposing to serve 11 single-family homes must meet the planning,

engineering, and design standards for Group A public water systems because the design

population exceeds 24 people (WAC 246-291-200(2)).

11 dwelling units x 2.5 people per dwelling unit = 28 people

Example 3-5

A proposed catering business in Western Washington will employ 20 daytime employees and

have no visitors. The proposed building will have its own drinking water system, using a permit-

exempt well for commercial purposes. The area around the building to be irrigated is 3,000 sq.

feet. A fire pond filled by a nonpotable water supply will meet the building’s fire-suppression

requirements. The fire pond and associated fire-suppression piping have no physical connection

with the potable water system.

To determine the need for a water right, follow the steps below.

Step 1: Apply the fixture weight to each fixture type (Table 3.4), and determine the building’s

total fixture units.

Fixture Type

Number of Fixtures x Fixture Weight = Fixture Units

Drinking fountain

2

0.5

1

Toilet (tank flush)

4

2.5

10

Urinal

1

3

3

Lavatory

2

1

2

Kitchen sink

2

1.5

1.5

Dishwasher

2

1.5

3

Total

22

Step 2: Round the total fixture units from 22 up to 25 (the next increment in Table 3.5).

Step 3: Use Table 3.5 to establish peak hourly demand for internal use within the building.

Nonresidential internal PHD is 18 gallons per minute. If the irrigation system is not

operated while the building is occupied, then the estimated design PHD should be 18

gpm. If the irrigation system can be operated while the building is occupied, then the

design estimate for PHD should include both the internal PHD (18 gpm in this example)

plus the peak flow rate of the irrigation system.

Check water right:

✓ To estimate nonresidential MDD, multiply 20 workers x 15 gallons per day (per Table 3.3).

Therefore, the nonresidential MDD is 300 gpd.

Group B Water System Design Guidelines (DOH 331-467) Page 25

September 2018

The water supply for food preparation is estimated at 1,000 gpd. Total water use in the

building is 1,300 gpd. This is less than the 5,000 limitation on a commercial/industrial

permit-exempt well. OKAY

✓ Total irrigated area is below the maximum 21,780 square feet allowed without a water right.

OKAY

3.4 Fire Suppression

If the project is in a Critical Water Supply Service Area, the water system design must provide

the minimum stipulated fire suppression capacity (WAC 246-291-090 (1)). The local fire

authority may require greater fire suppression capacity for the proposed water system. Minimum

fire-flow requirements for public water systems in a Critical Water Supply Service Area are in

WAC 246-293-640.

If the project is not in a Critical Water Supply Service Area, we recommend you consult with the

local fire authority to determine what, if any, fire suppression capacity it expects from the

proposed water system.

3.4.1 Design for Individual Structure Sprinkler Systems

If the water system will provide the direct supply of water to individual sprinkler systems in

homes or other nonresidential structures, you must include the added supply and pressure

requirements these sprinkler systems demand (WAC 246-291-200 and -210).

If you intend to design a water system capable of providing fire flow, either through hydrants or

individual structure sprinklers, a professional engineer licensed in Washington State must

prepare and submit the water system design (WAC 246-291-120(4)). For further guidance,

please see our Water System Design Manual (331-123) online at

doh.wa.gov/portals/1/Documents/pubs/331-123.pdf.

References

WSDOH, 2009. Water System Design Manual, DOH 331-123, Washington State Department of

Health, Olympia, WA.

American Association for Vocational Instructional Materials. 1982. Planning for an Individual

Water System, 4th Edition, American Association for Vocational Instructional Materials,

Athens, GA.

AWWA. 1984. Design and Construction of Small Water Systems, American Water Works

Association, Denver, CO.

Group B Water System Design Guidelines (DOH 331-467) Page 26

September 2018

Chapter 4 Sources of Supply

Chapter 4 covers design considerations for your water source(s). The first consideration and a

potential limiting factor in small water system design is the capacity of the source(s). The goal of

your water system design is to provide the quantity of water needed to reliably meet the expected

maximum day and peak hourly demands of your future customers.

The rule permits two types of sources for new or expanding Group B water systems: a well or an

intertie with an existing, approved public water system (chapter 246-291 WAC).

If you intend to supply your proposed water system with an intertie, please refer to Section 4.4.

The rest of this chapter is devoted exclusively to using a well as your Group B water supply.

4.0 Well Construction

In your workbook, you must demonstrate that your Group B groundwater supply:

• Is a drilled well, constructed according to chapter 173-160 WAC (WAC 246-291-

125(1)). We will not approve springs, surface water, dug wells, and wells found to be

under the direct influence of surface water as a Group B water supply.

• Is capable of reliably delivering the minimum supply described in WAC 246-291-125

(4).

• May be used in compliance with Washington’s Water Code and other applicable

regulations (WAC 246-291-125(3)) and the water right discussion in Chapter 3.

• Is physically connected to the distribution system. Trucked or hauled water is not an

acceptable Group B public water supply, regardless of the trucked water source (WAC

246-291-125(1)).

• Meets all primary water quality standards without needing treatment (WAC 246-291-

125(1) and -170(5)).

• Is protected adequately from potential contamination sources. Protective covenants

establishing the minimum sanitary control area must be filed for each source (WAC 246-

291-125(5)).

A totalizing source meter and sample tap are required on each new supply source (WAC 246-

291-200). In addition, we recommend individual service meters on each service connection.

The well casing must extend at least six inches above the finished ground surface, or at least six

inches above the pump house finished floor. Further, the top of the well casing must be at least

24 inches above the 100-year flood elevation (WAC 246-291-125(1) and chapter 173-160

WAC). Your submitted workbook must document the height of the well casing above the

finished ground surface or floor. You may find flood-mapping information at your local planning

office. If your well is in the 100-year flood plain, you must note this on your drawings. (See

Section 5.3.)

The pitless adaptor or pitless unit, and the well cap must be manufactured according to Standard

PAS-97 (2012) (WAC 246-291-200 (13)).

Group B Water System Design Guidelines (DOH 331-467) Page 27

September 2018

4.1 Source Water Quantity

Groundwater is the most common form of public drinking

water supply in Washington State. Your groundwater source(s)

must provide sufficient water to meet the Maximum Daily

Demand (MDD) for your water system (WAC 246-291-

125(4)). If your well can produce the maximum daily demand,

but not the Peak Hour Demand (PHD), you must provide

equalizing water storage (WAC 246-291-200 (5)). If storage is

required, a professional engineer may need to design the water

system (WAC 246-291-120(4)).

4.1.1 Well Log

The well log, otherwise known as a “water well report,”

provides important information about the construction of your

well and its vulnerability to contamination. It also contains information about your aquifer and

sometimes your well capacity and pump setting. You must include a copy of the well log in the

workbook, even when the design intends to use an existing well (WAC 246-291-125(3)).

If a well log is not available, we may not approve the source, or we may require additional

information before considering the source for approval.

4.1.2 Pump Tests

All wells submitted for approval must be pump tested (WAC 246-291-125(3)). The goal of the

pump test is to demonstrate the source’s capacity to meet or exceed proposed water system

demand during a range of conditions likely to occur over the course of a year and the life of the

well. See Appendix F for detailed pump test guidance.

The pump test must provide the:

• Static water level.

• Sustainable yield.

• Drawdown.

• Recovery rate.

• Duration of pumping.

To demonstrate sustainable yield, a successful pump test must show the proposed well (or

combination of wells) can provide a sustainable and reliable yield equal to or exceeding the

minimum supply requirements in WAC 246-291-125 (4)(d). In addition, the water level in the

proposed well must recover to 95 percent or more of the pre-test water level within a normal 24-

hour operational period.

A successful pump test will provide data needed for source approval, well design, and water

system planning decisions. By analyzing the pump test data, you can:

• Identify the capacity and reliability of your well.

• Establish well pump settings (depth and discharge rate).

• Define the area of influence of your well.

• Identify whether the system requires a water supply contingency plan because of a low-

yield well (defined as 5.0 gpm or less) (WAC 246-291-140 (1)).

Group B Water System Design Guidelines (DOH 331-467) Page 28

September 2018

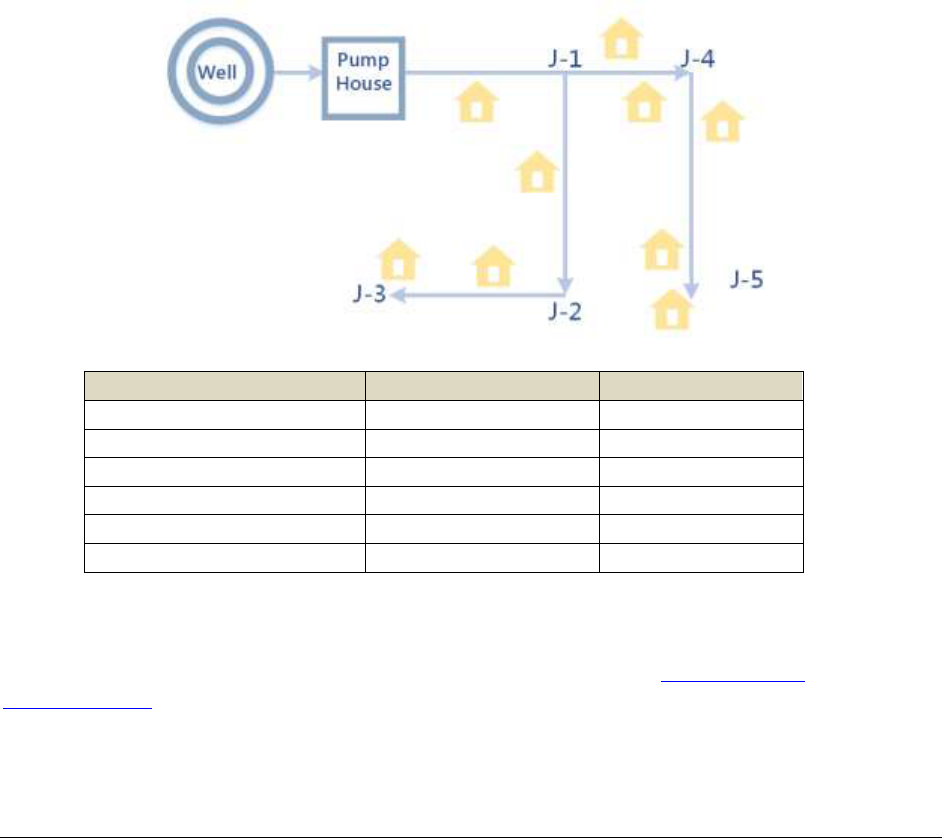

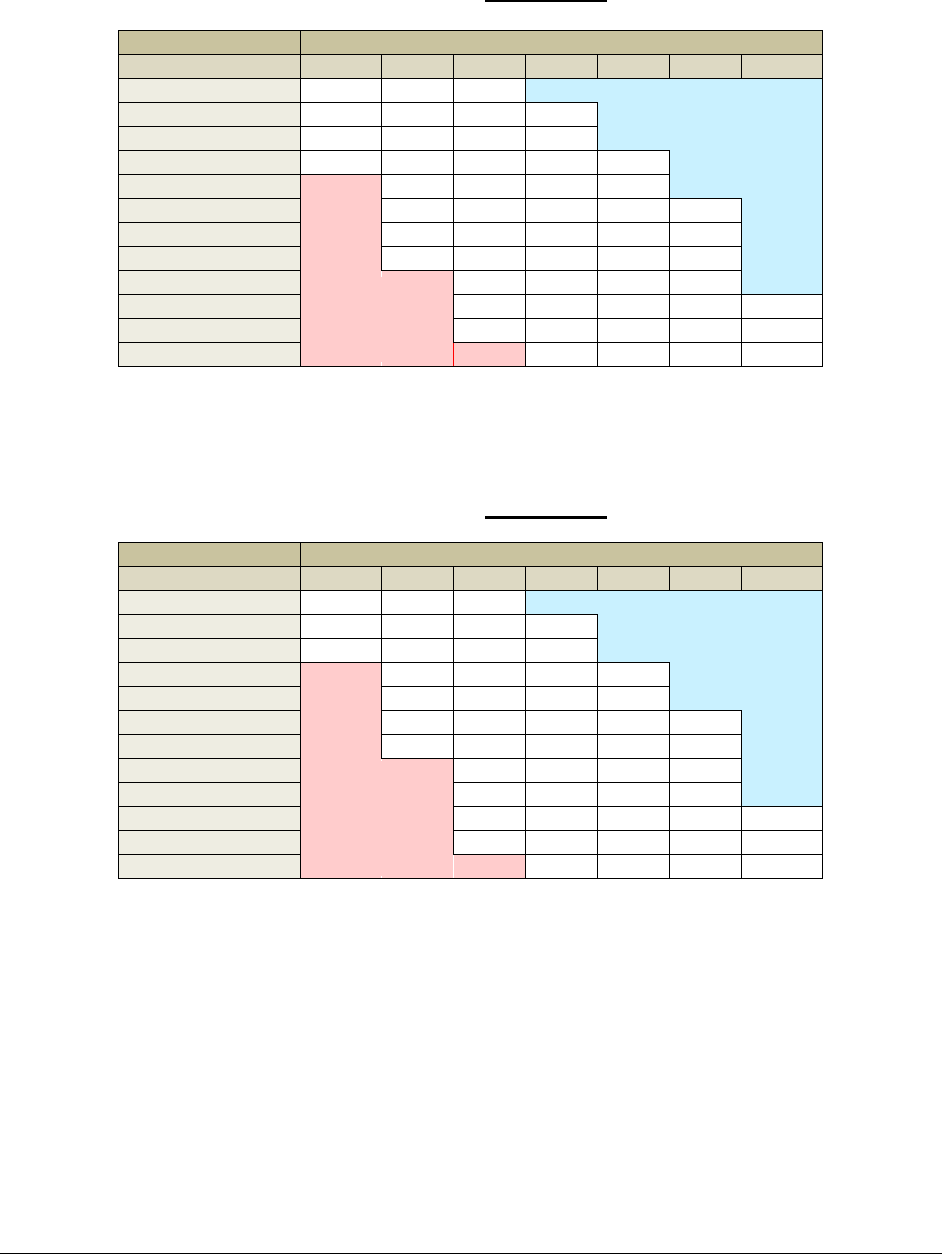

4.1.2.1 Elements of a Pump Test

A pump test is an aquifer and well stress test. The test subjects the well to a series of

controlled pump and recovery (rest) challenges. Pumping rates and the water level in the well

are monitored and recorded. The designer can use an analysis of the data to identify aquifer

characteristics, such as transmissivity, hydraulic capacity, and specific yield.

A design engineer can use the capacity of the well (in gallons per minute), established from

the pump test, and the required pump head (in feet) to select the proper pump size, pump

placement and determine overall well efficiency.

Because aquifer conditions vary, Appendix F describes three different pump test procedures,

each suited for different hydrologic conditions.

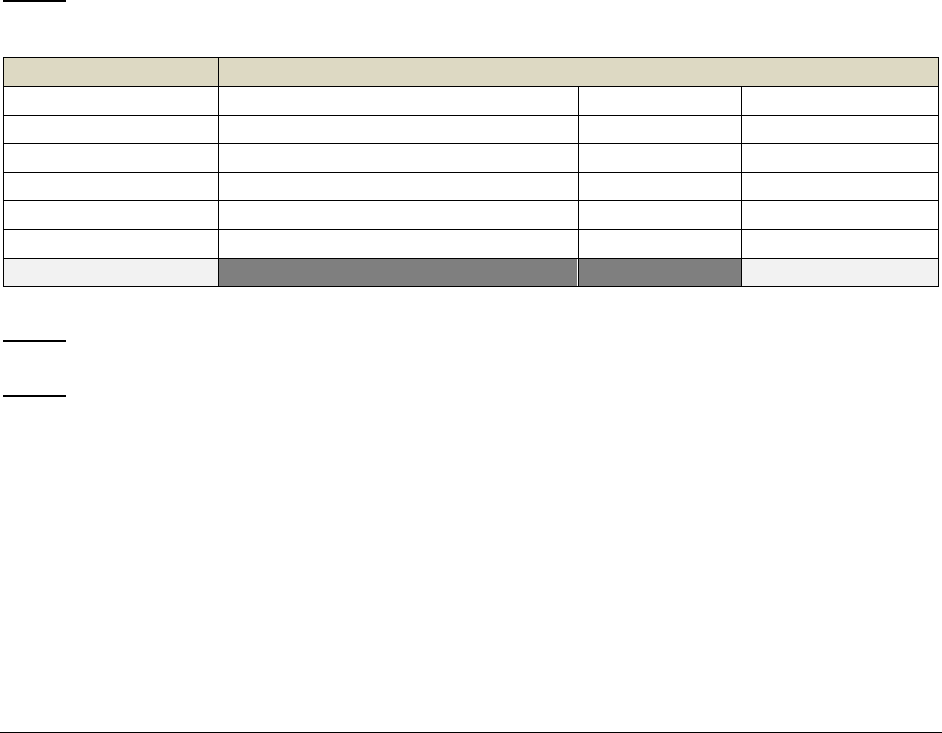

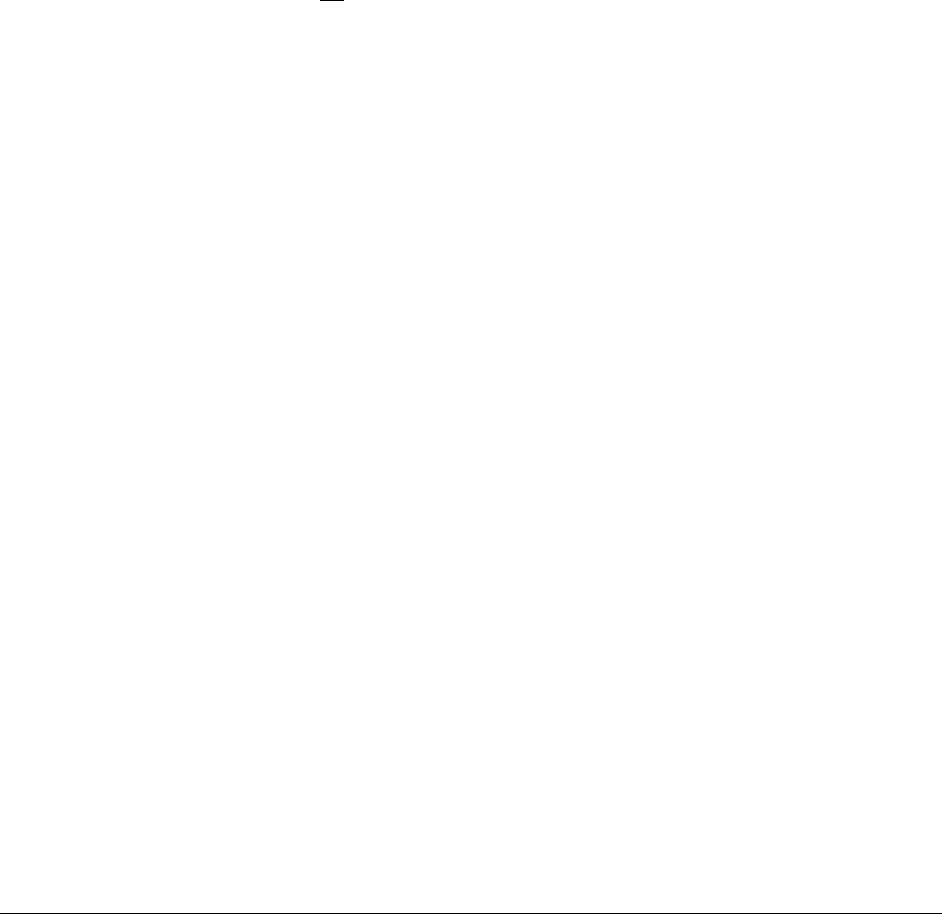

Test Procedure

Application

1

Standard Step Drawdown/ Constant

Rate

Complex or unknown hydrologic settings

2

Extended Step Drawdown

Small systems with low demand located in high

yield aquifers

3

Alternating Pump and Recovery

Very small systems in very low yield aquifers

Every pump test must include regularly recorded pumping and water level measurements

taken before the test begins (pre-pumping conditions), during the pumping phase

(drawdown), after the pump is shut off, and as water levels return to pre-pumping or near

normal conditions (recovery). Pre-pumping and recovery water level measurements are as

important as measurements taken during the pumping phase of a test.

A pump test must be long enough to demonstrate that the well can produce the minimum

supply requirements defined in WAC 246-291-125 (4)(d) and recover to at least 95 percent

of pre-pumping levels within a normal 24-hour operational period. The length of an

individual pump test will vary based on the structure of the test and the aquifer conditions.

Pump tests may take longer than 24 hours to complete and still be considered successful. It is

the analysis of the data collected during the pump and recovery tests that demonstrates

sustainable operating conditions. The designer is responsible for ensuring that a pump test

provides sufficient data to achieve its objectives.

To conduct a pump test on an existing drinking water supply (to an individual home or an

existing Group B water system), you must disconnect the pump discharge from the

distribution system and any pressure tanks. This will allow you to measure the unrestricted

pump discharge. Be sure to disinfect the well and pump discharge piping after completing the

pump test and before placing the well pump back into service. Follow the disinfection

standards in WAC 246-291-220.

If not already present, the designer must install an access port permitting “depth to water”

measurement prior to the pump test (WAC 173-160). We recommend that you measure water

levels to the nearest 0.01 ft. However, not all measuring devices have the same level of

Group B Water System Design Guidelines (DOH 331-467) Page 29