The U.S. Department of Energy (DOE) is pursuing an all-of-

the-above approach to developing every source of American

energy. The Ofce of Energy Efciency and Renewable Energy

(EERE) leads DOE efforts to build a strong clean energy

economy, a strategy that is aimed at reducing our reliance on

foreign oil, saving families and businesses money, creating

middle-class jobs, and reducing pollution.

This strategy will position the United States as the global leader

in clean energy, increasing our nation’s economic competitiveness.

In 2012, $268 billion was invested globally in clean energy, a

500% increase since 2004.

1

Trillions of dollars will be invested

in the coming decades. Clean energy represents one of the most

important economic development races of the 21st century. We

face a stark choice—the clean energy technologies of tomorrow

can be invented and manufactured in Indiana and the rest of

the United States for domestic use and export around the world,

or we can cede global leadership and import those technologies

from China, India, Germany, and elsewhere.

Indiana’s Clean

Energy Resources

and Economy

• CleanEconomyJobs()

• AverageAnnualGrowthRateofClean

EconomyJobs(–)

• AverageAnnualWageofCleanEconomy

Jobs()

Strongincleanenergymanufacturing

renewablesandeciencytechnologies

Indianaranksinthetopthirdofstatesinwind

energypotentialwithacapacityofmorethan

megawatts—enoughtogeneratemore

thanfourtimesthestate’scurrentelectricity

consumption

Thefourutility-scalewind

powerplantscurrentlyoperatinginIndiana

generatemorethanmegawatts—upfrom

virtuallyzeroin

SeveraldozenIndiana

companiesproducecomponentstoolsor

materialsforthewindenergyindustry

Indiana’sautomotivemanufacturingindustry

employedmorethanpeopleand

producedmorethanbillionworthofgoods

in

SeveralofIndiana’sautoandauto

partmanufacturershaveenteredorare

preparingtoenterthegrowingclean

transportationsector

Indianaisoneofstateswithabinding

energysavingstargetTheannualsavings

targetstartsatinandwillrampup

toin

Bythiseortisexpected

tosavemorethanmillionmegawatt

hours—millionworthofelectricity—per

yearstatewide

Indianautilitycompaniesalso

sponsorrebateprogramsforenergy

eciencyandrenewableenergyaswellasa

loanprogramforresidentialenergyeciency

improvements

Indiana

This Indiana State Summary educates policymakers and the public

about EERE investments and their positive impacts in Indiana.

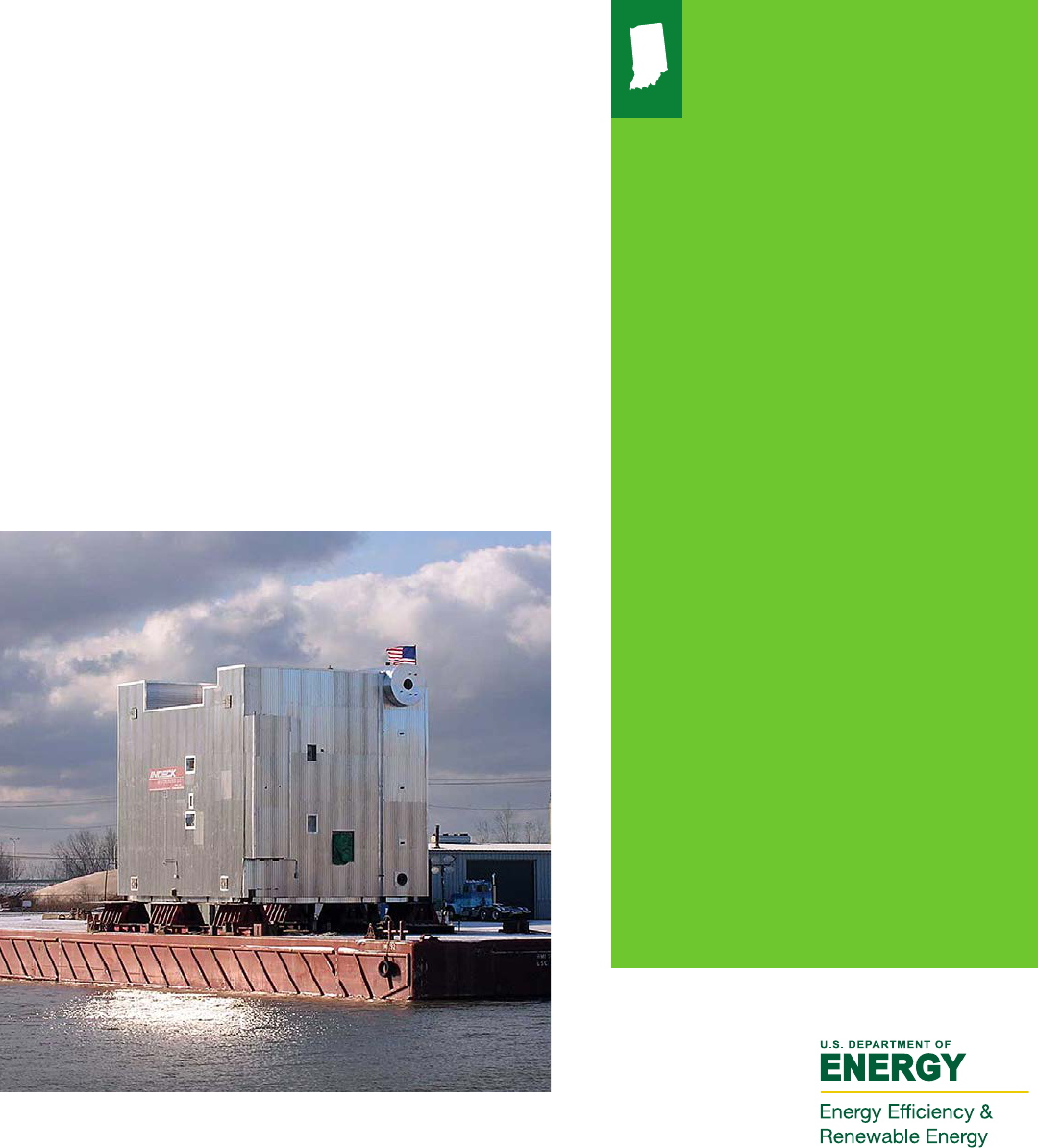

ArcelorMittal USA, Inc. installed an energy-ecient boiler at its Indiana

Harbor Steel Mill that has the capacity to reduce carbon dioxide

emissions by 330,000 tons annually.

Photo from ArcelorMittal

2

Indiana State Summary: EERE Investments in Indiana

EERE and Indiana

EERE helps create Indiana’s clean energy economy today,

developing and delivering innovative, market-driven solutions

for the following:

• Sustainable transportation – making transportation

cleaner and more efcient through solutions that put

electric drive vehicles on the road and replace oil with

clean domestic fuels

• Renewable electricity generation – reducing the cost of

renewable energy through solutions that squeeze more

usable power from sustainable resources and improve

the economics of manufacturing and installation

• Energy-saving homes, buildings, and manufacturing –

developing cost-effective energy-saving solutions that

help make our country run better through increased

efciency—promoting better plants, manufacturing

processes, and products; more efcient new homes and

improved older homes; and other solutions to enhance

the buildings in which we work, shop, and lead our

everyday lives.

EERE Investments in Indiana

EERE invests in Indiana through a broad range of clean

energy projects, including vehicles, geothermal, solar, wind,

and other technologies. Through the research, demonstration,

and deployment activities we conduct with Indiana and its

businesses, universities, nonprots, and local governments,

EERE supports cities, communities, and families to develop

innovative, cost-effective clean energy solutions.

Sustainable

Transportation

Largest U.S. Hybrid Electric Vehicle Supplier Expands

Manufacturing Facility to Create Jobs and Invigorate

Local Community

Kokomo, Indiana

EERE investment: $96.7M

Delphi, the largest North American supplier for hybrid

electric vehicle power electronics components and energy

management systems, is expanding its Kokomo manufac-

turing facility with an EERE investment of $89.3 million.

Delphi has already created more than 198 direct jobs, and

expects the expansion to create more than 900 direct and

indirect jobs.

9

EERE provided Delphi an additional $7.4

million in January 2010, which the company also matched,

to develop a novel low-temperature combustion system for

light-duty vehicles that could improve fuel economy by at

least 25%.

10

In addition, in June 2012, Delphi competed

and was selected for funds through EERE’s Innovative

Manufacturing Initiative for the development of lasers to

be used in a new production process for fuel injectors. This

new process is expected to yield energy savings of up to 25%

relative to current practices.

11

Hybrid Electric Drive Systems Come to the Commercial

Truck Market

Indianapolis, Indiana

EERE investment: $62.8M

EERE’s investment in Allison Transmission, combined with

the company’s matching $62.8 million investment, will fund

the retooling of a facility in Indianapolis for subassembly and

testing of its H3000 hybrid drive systems for the commercial

truck market. Allison estimates that this electric drive tech-

nology can improve fuel economy by 25%–35% compared to

conventional trucks with internal combustion engines. Since

the end of November 2012, Allison has had the capacity in

place to annually produce 20,000 H3000 hybrid drive systems

for medium- and heavy-duty sized trucks and buses.

12

Allison Transmission, with EERE’s support, is developing electric

drive technology which is estimated to improve fuel economy by

25%–35% for commercial trucks.

Photo from iStock 2312011

3

Indiana State Summary: EERE Investments in Indiana

Leading Automotive Parts Manufacturer Develops

Lower-Cost, Higher Performance Hybrid Electric

Motors and Controls

Pendleton, Indiana

EERE investment: $60.2M

Remy International is a leading global manufacturer and

remanufacturer of automotive parts, including starters,

alternators, and hybrid motors. EERE is partnering with

Remy to develop a standardized platform for lower-cost,

higher-performance hybrid electric motors and controls, as

well as to retool and expand its U.S.-based manufacturing

facilities. By creating a family of standardized electric drive

motors and scaling their production, the company hopes it

will be able to reduce the costs of its products for existing

customers in the automotive and heavy-duty vehicle markets.

The rst phase of the project, which refurbished an existing

facility in Pendleton, is complete and has supported 210 direct

jobs. Remy is also investing $60.2 million in the project.

13

EERE’s SuperTruck Initiative – Improving

the Tractor-Trailers that Bring Goods to Our

Communities

The SuperTruck Initiative is an ongoing collaborative

effort between EERE and private industry that seeks to

revolutionize on-highway commercial transportation by

improving the freight hauling efciency of long-haul Class

8 tractor-trailers by more than 50%. All of the major truck

and diesel engine manufacturers in the United States are

participating in this effort.

• Developing and Demonstrating Technologies that

Improve Engine Efciency

Fort Wayne, Indiana

EERE investment: $31M

Navistar, working in cooperation with DOE’s Lawrence

Livermore National Laboratory and Argonne National

Laboratory, is developing and demonstrating technologies

to improve truck and trailer aerodynamics, combustion

efciency, waste heat recovery, hybridization, idle reduction,

and reduced rolling resistance tires. Navistar, conducting

a majority of the work in Fort Wayne, is investing an

additional $52 million in the project.

14

• Improving Engine Performance

Columbus, Indiana

EERE investment: $53.8M

Cummins, the world’s largest diesel engine manufacturer,

received funds from EERE for work on in two areas:

advanced engine technology and light-duty vehicles.

Cummins’ work on Class 8 heavy-duty trucks includes

the development and demonstration of a highly efcient

and clean diesel engine, an advanced waste heat recovery

system, an aerodynamic Peterbilt tractor and trailer

combination, and a fuel cell auxiliary power unit to reduce

engine idling.

15

Cummins’ work on light-duty vehicles are

to develop a fuel-efcient, low-emissions diesel engine

that is 40% more fuel efcient than conventional gasoline

technology, while meeting 2010 EPA emissions standards.

Cummins contributed $55.3 million to these projects.

These funds will be used to develop a fuel-efcient,

low-emissions diesel engine that is 40% more fuel efcient

than conventional gasoline technology, while meeting 2010

EPA emissions standards.

16

EERE has supported Indiana’s auto and auto part manufacturers

as they enter or prepare to enter the growing clean transportation

sector.

Photo from iStock 10427481

4

Indiana State Summary: EERE Investments in Indiana

Adopting Smart Transportation Solutions

Mooresville and Crown Point, Indiana

EERE investment: $30K anually to each coalition

EERE coordinates a network of nearly 100 Clean Cities

coalitions—self-organized groups of local community,

government, and business stakeholders whose efforts to adopt

smart transportation solutions have displaced more than 4.5

billion gallons of gasoline and diesel since 1993. Indiana is

home to two Clean Cities coalitions: Greater Indiana Clean

Cities and South Shore Clean Cities. In 2011, these two

coalitions reduced fuel consumption by the equivalent of

nearly 18 million U.S. gallons of gasoline and prevented more

than 130,000 tons of greenhouse gas emissions. Together, the

coalitions include more than 350 businesses, local govern-

ments, and other organizations, and work to promote the use

of the more than 500 alternative fuel and charging stations in

Indiana. In 2011, the two coalitions leveraged DOE’s support

to raise more than $14 million from businesses, local govern-

ments, other organizations, and non-DOE grants.

Renewable

Electricity

Generation

Ball State University Completes Largest U.S.

Ground-Source Geothermal System, Saving Millions

in Operating Costs

Muncie, Indiana

EERE investment: $5M

EERE has partnered with Ball State University in Muncie to

install a campus-wide ground-source geothermal heating and

cooling system—currently the nation’s largest. The university

anticipates that this system will help save $2 million annually

in operating costs and cut the university’s carbon footprint

in half. Ball State’s geothermal system will replace four aging

coal-red boilers to provide renewable power that will heat

and cool 47 university buildings, comprising 5.5 million

square feet on the 660-acre campus. The rst half of the

project was completed in March 2012, with the nal half

scheduled for completion in 2014. Nearly every component

of the system was manufactured in the United States, and

Ball State contracted with more than 50 Indiana rms to

complete the project.

17

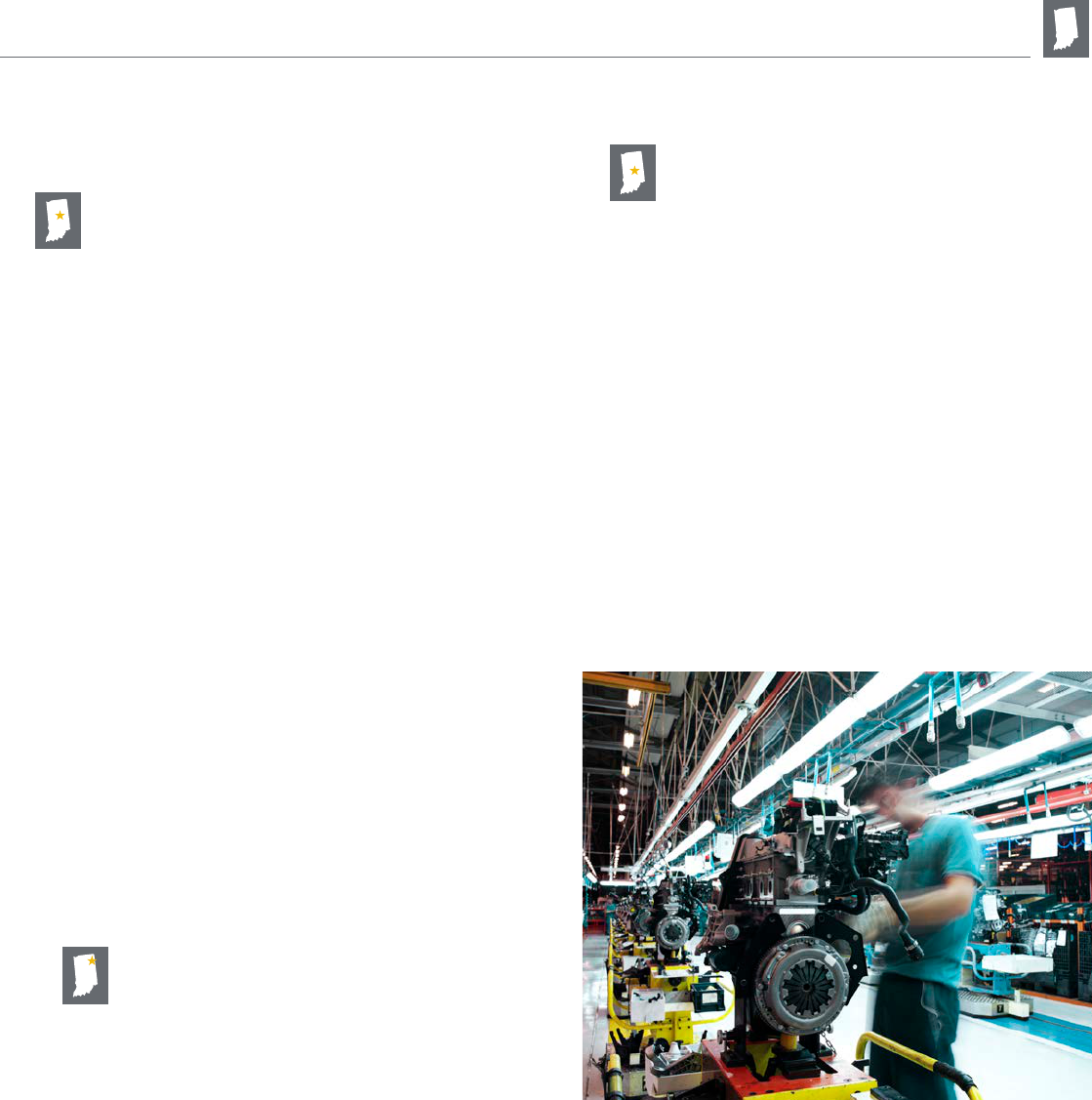

EERE sponsored Ball State University’s campus-wide geothermal

system, which is expected to save $2 million annually in operating

costs and cut the university’s carbon footprint in half. Here,

geothermal boreholes are dug to install the system next to an

existing coal-fired power plant.

Photo from Ball State

Educating Workers, Consumers, and Students about

Wind Power

Statewide

EERE’s Wind Powering America (WPA) is a nationwide

initiative designed to educate, engage, and enable critical

stakeholders to make informed decisions about how wind

energy contributes to the U.S. electricity supply. In Indiana,

WPA has education and workforce training programs at

Purdue University-Calumet in Hammond and at Ivy Tech

Community College in Lafayette. WPA conducted various

wind resource analysis exercises, developed a small wind

consumer’s guide for the state, and supports school wind

projects at high schools, colleges, and universities in Akron,

Albion, Francesville, Union City, and Upland.

Indiana has the wind energy potential of over 40,000 megawatts,

which is more than four times the state’s current electricity

consumption.

Photo from Iberdrola Renewables, Inc., NREL 16706

5

Indiana State Summary: EERE Investments in Indiana

Energy-Saving

Homes, Buildings,

and Manufacturing

Steel Mill Powered by Waste Heat Recovery System

Improves Competitiveness

East Chicago, Indiana

EERE investment: $31.6M

EERE worked with ArcelorMittal USA, Inc. to install an

efcient recovery boiler to use waste heat generated during

iron‐making operations to produce electricity and steam

onsite at the company’s Indiana Harbor Steel Mill in East

Chicago, Indiana. The steam is being used to drive existing

turbogenerators onsite, creating enough electricity to power

the equivalent of 30,000 households each year and reducing

carbon dioxide emissions by 330,000 tons annually, which

is equivalent to removing approximately 60,800 cars from

the road. The project is estimated to have created 360 jobs

related to the design and manufacture of the equipment alone;

employ 200 local construction workers; and, by reducing

energy costs, help support 5,900 jobs associated with the mill.

18

Deploying Clean Energy Solutions

in Indiana Communities

EERE invests in the deployment of energy efciency and

renewable energy projects in communities across the Hoosier

State, catalyzing economic development, creating jobs, gener-

ating clean energy, and reducing utility bills. Of the more

than $249 million in American Recovery and Reinvestment

Act (ARRA) funds allotted to the State of Indiana from

EERE specically for deployment projects, more than

99% has been spent as of March 2013 through the Energy

Efciency and Conservation Block Grant Program, State

Energy Program, and Weatherization Assistance Program.

Building Clean Energy Infrastructure

With nancial and technical support from EERE, energy

ofcials at the state level and in 34 communities have selected

and overseen the completion of hundreds of projects that are

delivering the benets of clean energy to citizens throughout

Indiana. EERE allocated $116 million in ARRA funds to

support activities that

• Increased energy efciency and cost savings of nearly

1,000 buildings (more than 20 million square feet)

through building retrots

• Installed approximately 20 renewable energy systems,

with a total capacity of more than 500 kilowatts of

solar energy systems

• Funded nearly 130 workshops, teaching nearly 5,000

people to perform energy audits and install renewable

energy systems

• Installed more than 6,000 energy-efcient streetlights

and more than 3,000 energy-efcient trafc signals.

19

Weatherizing Homes for Lower Income Families

Indiana has spent more than 99% of the more than $133

million in ARRA funds it received to weatherize approxi-

mately 23,000 homes, exceeding its goal. This resulted in

annual energy savings of approximately 700 billion British

thermal units and prevented more than 60,000 metric tons of

carbon pollution, the equivalent of taking more than 12,000

passenger vehicles off the road for a year.

20

The projects have

enabled income-eligible families to save hundreds of dollars

per year on heating and cooling bills by improving their

homes’ energy efciency as well as the health and safety of

home environments.

21

ARRA funds have enabled the state of Indiana to weatherize

approximately 25,000 homes.

Photo from iStock 5392656

6

Indiana State Summary: EERE Investments in Indiana

Deployment Project Examples

in Indiana Communities

City of Carmel Replaces Street Lights and Deploys

Community Wind Turbines

Carmel, Indiana

EERE investment: $633K

The City of Carmel replaced half of its existing street lights

with light-emitting diodes and deploy small wind turbines to

power the city’s sewer treatment plant. In addition to creating

30 jobs and saving energy, the project is leveraging hundreds

of thousands of dollars from state and local sources.

Purdue Develops the U.S. Renewable Energy Workforce

West Lafayette, Indiana

EERE investment: $500K

Purdue University has established a comprehensive wind

energy program with educational and research components.

Funding has helped Purdue develop graduate and undergrad-

uate curricula for energy engineering, focusing on wind energy

and including a wind energy certicate program. This funding

will help develop the U.S. renewable energy workforce.

Indianapolis Harnesses the Sun and Wind to Power

City Infrastructure

Indianapolis, Indiana

EERE investment: $250K

Indianapolis installed a solar photovoltaic system, solar thermal

system, and wind-powered outdoor lighting on the City-County

Building, a 731,119-square-foot downtown landmark.

22

Warrick County Saves Energy and Money through

Efciency Measures

Warrick County, Indiana

EERE investment: $58K

Warrick County retrotted its lighting in the Warrick

County Courthouse and the Warrick County Security

Center. The county has already realized more than $8,000

in energy savings.

23

Metal Halide Lighting Puts Out More Light for

Less Energy

Shelbyville, Indiana

EERE investment: $500K

Ryobi Die Casting USA used this investment, administered

through Indiana’s Conserving Hoosier Industrial Power

program, to replace the high bay xtures in all three of its

manufacturing buildings with Pulse Start Advanced Metal

Halide xtures. These xtures increased lighting on the shop

oor by 300%, while using only 45% of the initial power

input. The Pulse Start xtures were designed and manufac-

tured in Casey, Illinois.

MD Logistics Upgrades Heating, Cooling, Lighting,

and Control Systems

Plaineld, Indiana

EERE investment: $212K

MD Logistics used this investment, also administered

through Indiana’s Conserving Hoosier Industrial Power

grant program, to retrot heating, ventilating, and air

conditioning (HVAC); lighting; and control systems at its

facility. The company replaced three HVAC units with high

efciency units, retrotted eight cooling units with ultraviolet

C lighting, and installed direct digital control systems to

reduce winter heating costs and summer cooling demand.

MD Logistics also had its warehouse lighting upgraded to T5

High Output uorescent xtures with motion sensors to turn

lights off when an area was unoccupied.

7

Indiana State Summary: EERE Investments in Indiana

References

1

“Who’s Winning the Clean Energy Race?” Pew Charitable Trusts, April 2012.

http://www.pewtrusts.org/uploadedFiles/wwwpewtrustsorg/Reports/Clean_Energy/Clean%20

Energy%20Race%20Report%202012.pdf.

2

“Sizing the Clean Economy: The Clean Economy in the State of Indiana.” The Brookings Institution

and Battelle, July 2011. http://www.brookings.edu/~/media/Series/Clean%20Economy/18.pdf.

3

“Wind Resource Potential.” EERE, 2010. http://www.windpoweringamerica.gov/windmaps/

resource_potential.asp.

4

“NREL’s Wind Powering America Team Helps Indiana Develop Wind Resources.” NREL, October

2010. http://www.nrel.gov/docs/fy11osti/48938.pdf.

5

“Annual State Personal Income and Employment” and “Gross Domestic Product by State.” U.S.

Bureau of Economic Analysis, 2012. http://www.bea.gov/iTable/iTable.cfm?reqid=70&step=1&isuri=1

&acrdn=4#reqid=70&step=1&isuri=1; http://www.bea.gov/iTable/iTable.cfm?reqid=70&step=1&isuri=1

&acrdn=1#.

6

“Cause #42693.” Indiana Utility Regulatory Commission, December 2009. http://www.in.gov/iurc/

files/Cause_No._42693.pdf.

7

Assumes savings equal to 2% of 2010 electricity consumption.

8

“Database of State Incentives for Renewables & Eciency,” EERE, 2012. http://www.dsireusa.org/.

9

“Low Cost U.S. Manufacturing of Power Electronics for Electric Drive Vehicles.” Delphi Automotive

Systems, May 2012. http://www1.eere.energy.gov/vehiclesandfuels/pdfs/merit_review_2012/

adv_power_electronics/arravt022_ape_grant_2012_p.pdf.

10

“2011 DOE Vehicle Technologies Review: Gasoline Ultra Fuel Ecient Vehicle.” Delphi Automotive

Systems, May 2012. http://www1.eere.energy.gov/vehiclesandfuels/pdfs/merit_review_2012/

adv_combustion/ace064_confer_2012_o.pdf.

11

“Innovative Manufacturing Initiative.” EERE, 2012. http://www5.eere.energy.gov/projects/foa/

project/innovative-manufacturing-initiative.

12

“Electric Drive Component Manufacturing Facilities.” Allison Transmission, May 2011.

http://www1.eere.energy.gov/vehiclesandfuels/pdfs/merit_review_2011/adv_power_electronics/

arravt023_ape_tuttle_2011_p.pdf.

13

“Providing Vehicles OEMs Flexible Scale to Accelerate Adoption of Electric Drive Vehicles.” Remy

International, May 2012. http://www1.eere.energy.gov/vehiclesandfuels/pdfs/merit_review_2012/

adv_power_electronics/arravt025_ape_shives_2012_p.pdf.

14

“SuperTruck – Development and Demonstration of a Fuel- Ecient Class 8 Tractor & Trailer.”

Navistar, May 2012. http://www1.eere.energy.gov/vehiclesandfuels/pdfs/merit_review_2012/

veh_sys_sim/vss064_jadin_2012_o.pdf.

15

“Technology and System Level Demonstration of Highly Ecient and Clean, Diesel Powered Class 8

Trucks.” Cummins, May 2012. http://www1.eere.energy.gov/vehiclesandfuels/pdfs/merit_review_2012/

adv_combustion/ace057_koeberlein_2012_o.pdf.

16

“Recovery Act Announcement.” EERE, January 11, 2010. http://apps1.eere.energy.gov/news/

progress_alerts.cfm/pa_id=284.

17

“EERE Network News.” EERE, April 4, 2012. http://apps1.eere.energy.gov/news/archive.cfm/

pubDate=%7Bd%20%272012-04-04%27%7D.

18

“Steel Manufacturer Proves its ‘Mittal’ by Doing More with Less Energy.” DOE, November 2010.

http://energy.gov/articles/steel-manufacturer-proves-its-mittal-doing-more-less-energy.

19

“Recovery Act and the State Energy Program” and “EECBG Allocations for Indiana.” EERE, 2010.

http://www1.eere.energy.gov/wip/recovery_act_sep.html; http://www1.eere.energy.gov/wip/

eecbg_state_allocations.html.

20

“Greenhouse Gas Equivalencies Calculator.” EPA, 2010. http://www.epa.gov/cleanenergy/energy-

resources/calculator.html.

21

“Residential Energy Consumption Survey.” U.S. Energy Information Administration, 2009.

http://www.eia.gov/consumption/residential/.

22

“Greening of the City-County Building.” City of Indianapolis, 2011. http://www.youtube.com/

watch?v=ayJ5EykSisw.

23

“Indiana Energy Insights.” Indiana Oce of Energy Development, December 8, 2011.

http://indianaenergyinsights.blogspot.com/2011/12/warrick-county-lights-it-up-with-eecbg.html.

24

“Retrospective Benefit-Cost Evaluation of U.S. DOE Vehicle Combustion Engine R&D Investments:

Impacts of a Cluster of Energy Technologies.” DOE, May 2010.

http://www1.eere.energy.gov/analysis/pdfs/advanced_combustion_report.pdf.

25

“Retrospective Benefit-Cost Evaluation of DOE Investment in Photovoltaic Energy Systems.” DOE,

August 2010.

http://www1.eere.energy.gov/analysis/pdfs/solar_pv.pdf.

26

“Retrospective Benefit-Cost Evaluation of U.S. DOE Wind Energy R&D Program,” DOE,

June 2010. http://www1.eere.energy.gov/analysis/pdfs/wind_bc_report10-14-10.pdf.

27

National Research Council. Energy Research at DOE: Was It Worth It? Energy Eciency and Fossil

Energy Research 1978 to 2000. Washington, DC: National Academies Press, 2001.

28

“DOE Hydrogen and Fuel Cells Program Record #12020,” DOE, September 27, 2012.

http://hydrogen.energy.gov/pdfs/12020_fuel_cell_system_cost_2012.pdf. Based on projections to

high-volume manufacturing.

29

“Retrospective Benefit –Cost Evaluation of DOE Investment in Photovoltaic Energy Systems.” DOE,

August 2010. http://www1.eere.energy.gov/analysis/pdfs/solar_pv.pdf.

30

“Retrospective Benefit-Cost Evaluation of U.S. DOE Wind Energy R&D Program,” DOE,

June 2010. http://www1.eere.energy.gov/analysis/pdfs/wind_bc_report10-14-10.pdf.

31

“Weatherization Assistance Program.” EERE, May 2009. http://www1.eere.energy.gov/wip/pdfs/

wap_factsheet.pdf.

32

“Building Technologies Program: History and Impacts.” EERE, 2013.

http://www1.eere.energy.gov/buildings/appliance_standards/history_and_impact.html.

33

“Energy Technology Solutions: Public-Private Partnerships Transforming Industry.” EERE, December

2010. http://www1.eere.energy.gov/manufacturing/pdfs/itp_successes.pdf.

34

“Facilitating Cost-Eective Federal Energy Management.” EERE, December 2012.

http://www1.eere.energy.gov/femp/pdfs/femp_fs.pdf.

Page 2: iStock 17393871; page 4: Dennis Schroeder, NREL 19156; page 5: Jim Tetro,

U.S. Department of Energy Solar Decathlon

Indiana State Summary: EERE Investments in Indiana

eere.energy.gov | EE.Communica[email protected].gov

DOE/GO-102013-3791 • March 2013

Printed with a renewable-source ink on

paper containing at least 50% wastepaper,

including 10% post consumer waste.

A Proven Track Record

Snapshot of National Outcomes from EERE Investments

• EERE’s $931 million investment in vehicles combustion engine R&D from 1986 to 2007 achieved a net benefit of $69 billion

(2008 dollars) in fuel savings for users of heavy-duty diesel trucks.

24

• EERE’s $3.7 billion investment in solar photovoltaic R&D from 1975 to 2008 resulted in a net economic benefit of $15 billion

(2008 dollars) due to module eciency and reliability improvements.

25

• EERE’s $1.7 billion investment in wind energy R&D from 1976 to 2008 resulted in a net economic benefit of $8.7 billion

(2008 dollars) due to wind turbine eciency, energy capture, and reliability improvements.

26

• A 2001 National Academy of Sciences analysis found that investments of $1.6 billion in energy eciency R&D in the first two

decades of DOE’s existence from 1978 to 2000 realized a net economic benefit of approximately $30 billion (1999 dollars).

27

• EERE research has helped reduce production costs of automotive lithium-ion batteries by more than 50% since 2008 and is on

track to reach its goal of enabling cost-competitive market entry of plug-in hybrid electric vehicles within the next 10 years.

• EERE’s activities to achieve cost-competitiveness for biofuels have resulted in the recent achievement of reaching a modeled

cellulosic ethanol production cost of $2.15 per gallon of ethanol (or $3.27 per gallon of gasoline equivalent).

• EERE’s eorts have reduced the projected costs of automotive fuel cells (assuming high-volume manufacturing) by more than

35% since 2008 and 80% since 2002—doubling the durability of fuel cells from 950 hours of demonstrated operation in 2006

to more than 2,500 hours of operation on the road.

28

• Without EERE involvement, the average solar photovoltaic (PV) module production cost per watt would have been $5.27 in

2008, rather than $1.92. EERE has accelerated solar industry progress by an estimated 12 years.

29

• Without EERE involvement, cumulative wind power deployment through 2008 would have been less than a third of actual

2008 levels. EERE has accelerated the overall progress of the wind industry by an estimated 6 years.

30

• More than 6,200,000 homes have been weatherized with EERE funding provided to states or leveraged from other sources with

EERE support since 1976—creating an average energy savings of $350 or more per year and avoiding $1.6 billion in energy costs

during winter 2005 alone for all households weatherized.

31

• Due to EERE appliance standards implemented through 2012, a typical household today already saves about $180 per year o its utility

bills. Households can expect to save more than $300 per year by 2030, as they replace their existing appliances with newer models that

use less energy—a cumulative savings to consumers of more than $900 billion by 2020, and more than $1.6 trillion through 2030. The

cumulative energy savings of these standards phased in through 2012 will be about 70 quadrillion British thermal units (quads) of energy

through 2020, and will amount to 120 quads through 2030. (The United States consumes a total of about 100 quads of energy per year.)

32

• EERE and its partners in the manufacturing sector have successfully launched 220 new, energy-ecient technologies, received 78

R&D 100 Awards, and delivered technical assistance to more than 33,000 industrial plants.

33

• Since 2005, EERE has facilitated $3.1 billion of eciency investments in federal government facilities from performance-based

contracts, which will result in energy cost savings of approximately $8.5 billion over the life of the energy-saving measures. The

savings on utility bills and operation and maintenance created through the facility upgrades will be used to pay for the project over

the term of the contract, and the agencies will continue to save money and energy after the contract term has ended.

34

The Oce of Energy Eciency and Renewable Energy is at the center of creating the clean energy economy today. We lead U.S. Department of Energy

eorts to develop and deliver market-driven solutions for renewable electricity generation; sustainable transportation; and energy-saving homes, buildings,

and manufacturing. To learn more about the activities of the Oce of Energy Eciency and Renewable Energy, visit eere.energy.gov. If you have questions

or comments about the information in this document, please contact us at EE.Communications@ee.doe.gov.

EERE’s Return on Investment

for Clean Energy Technologies

Sustainable Transportation

Renewable Electricity Generation

Energy-Saving Homes,

Buildings, and Manufacturing