Report No. CDOT-DTD-R-2002-12

Final Report

SAMPLING LOCATION IMPACT ON

MEASURED ASPHALT CONTENT OF HOT

MIX ASPHALT

Mohammad Abu-Hassan

University of Colorado at Denver

Final Report

November 2002

Technical Report Documentation Page

1. Report No.

CDOT-DTD-R-2002-12

2. Government Accession No.

3. Recipient’s Catalog No.

5. Report Date

November 2002

4. Title and Subtitle

SAMPLING LOCATION IMPACT ON MEASURED ASPHALT CONTENT

OF HOT MIX ASPHALT

6. Performing Organization Code

7. Author(s)

Mohammad Abu-Hasssan

8. Performing Organization Report No.

CDOT-DTD-R-2002-12

10. Work Unit No. (TRAIS)

9. Performing Organization Name and Address

Colorado Department of Transportation

4201 E. Arkansas Ave.

Denver, Colorado 80222

11. Contract or Grant No.

13. Type of Report and Period Covered 12. Sponsoring Agency Name and Address

Colorado Department of Transportation

4201 E. Arkansas Ave.

Denver, Colorado 80222 14. Sponsoring Agency Code

15. Supplementary Notes

Prepared in Cooperation with the U.S. Department of Transportation, Federal Highway Administration

16. Abstract

In May 2000, CDOT requested a forensic study of a project located on I- 25 north of Denver. The request was made because,

within a year of the 1997 overlay, longitudinal cracking appeared in the surface. Transverse cracks were attributed to reflective

cracking. However, the longitudinal cracks appeared to be surface initiated.

In October 2000, a forensic team reviewed the project and established a sampling and testing plan to take cores from the roadway.

Based on data analysis of the cores, the higher than expected in-place air voids, the low effective asphalt, and segregation within

the mat, all contributed to the early cracking.

The forensic team suggested that CDOT investigate the sampling locations for hot mix asphalt (HMA) that are allowed by

Colorado Procedure 41 to determine if all locations provide statistically equivalent asphalt contents.

This study indicates that there is no statistically significant difference in asphalt content of the allowed CDOT sampling locations.

This study suggests that no changes are needed to CP41 for sampling all hot mix asphalt.

17. Key Words

asphalt, segregation, binder, sampling location, sample

reduction, asphalt content

18. Distribution Statement

No restrictions. This document available to the public through

the National Technical Information Service

5285 Port Royal Road

Springfield, VA, 2216.

19. Security Classif. (of this report)

20. Security Classif. (of this page)

21. No. of Pages

40

22. Price

SAMPLING LOCATION IMPACT ON MEASURED

ASPHALT CONTENT OF HOT MIX ASPHALT

by

Mohammad Abu-Hassan

University of Colorado at Denver

Report No. CDOT-DTD-R-2002-12

Prepared by

Colorado Department of Transportation

Research Branch

Sponsored by the

Colorado Department of Transportation

In Cooperation with the

U.S. Department of Transportation

Federal Highway Administration

November 2002

Colorado Department of Transportation

Research Branch

4201 E. Arkansas Ave.

Denver, CO 80222

(303) 757-9506

DISCLAIMER

The content of this report reflects the views of the author, who is responsible for the facts and

accuracy of the data presented herein. The content does not necessarily reflect the official

views of the Colorado Department of Transportation or the Federal Highway Administration.

This report does not constitute a standard, specification, or regulation.

ACKNOWLEDGEMENTS

The author would like to express his gratitude to the many people who assisted in

performing this study. Thank you to Kim Gilbert (CDOT-Staff Materials) for setting up

sampling locations and dates.

Special thanks to the project managers and laborers who were very helpful with the

sampling.

The author gratefully acknowledges Naser Abu-Hejleh (CDOT-Research) who provided

numerous ideas and suggestions for data analysis.

iii

EXECUTIVE SUMMARY

A 1997 overlay on I-25 north of Denver experienced early cracking. While the

transverse cracking could be attributed to reflective cracking, there was no obvious

explanation for the longitudinal cracking. A team of national asphalt experts analyzed

cores and slabs from I-25 and concluded that a number of variables contributed to the

longitudinal cracking. One of the variables was low percent asphalt content. The asphalt

content was 0.5 % lower than the percent asphalt measured for Quality Control/Quality

Acceptance (QC/QA) data.

Investigation of the QC/QA data showed that project sampling was done from the

windrow. The cores taken for the study were believed to be more representative of the

material that was placed behind the paver. The study panel suggested that CDOT

investigate if the various sampling locations produced results that were consistent with

the material behind the paver.

Colorado Procedure 41 (CP 41) allows three different locations for sampling. These

locations are method A at the plant with a tube sampler, method B at the point of

delivery, and method C behind the paver. Method A has two different procedures for

sampling at the plant silo. With the first procedure the sampler tube is placed under the

silo before the discharge of mixture. With the second procedure the tube is swung

through the discharge steam. Method B is sampling from the point of delivery. Samples

may be taken from the windrow or the paver screws. Method C allows sampling behind

the paver. Samples may be collected either with or without a template.

This study compared the asphalt content (%) of samples taken by each method with the %

asphalt content of the mixture taken from behind the paver with a template. The purpose

was to ascertain if all methods provide unbiased test results of hot mix asphalt (HMA).

Statistically, it made no significant difference which sampling method was followed.

Therefore, CP41 and its various options should remain in place.

iv

TABLE OF CONTENTS

1.0 INTRODUCTION…………………………………………..…...1

2.0 SAMPLING (Colorado Procedure 41-98…………..………..….2

3.0 CP 41 SAMPLING BITUMINOUS PAVING MIXTURES……3

3.1 Tube Sampler……………………………………………..3

3.2 Point of Delivery …………………………………………3

3.3 Behind Paver…….………………………………………..4

4.0 REDUCING FIELD SAMPLES………………………………...5

5.0 DETERMINATION OF THE ASPHALT CONTENT…………5

6.0 RESULTS………………………………………………………..6

7.0 DISCUSSION OF RESULTS..………………………………….8

8.0 CONCLUSIONS………..…………………………………….…9

9.0 RECOMMENDATIONS………………………………………10

APPENDIX A…………………………………..….…………….…..A-1

APPENDIX B………………………………………………………..B-1

APPENDIX C………………………………………………………..C-1

v

LIST OF TABLES

2.1 Sampling locations and methods……………..……...………….2

6.1 %AC for all different methods in each project..…….…………..7

6.2 x,

σ

, and COV of ratios for each method…….…………………8

A-1 Ratio of % A.C. of all method to the % A.C. of samples behind the

paver with template………….……………………..……………….A-10

A-2 Probability density of each method……………………...…..A-11

LIST OF FIGURES

A-1 % AC for each project using all methods…………….……....A-1

A-2 Probability density of each method…………………………A-11

1

1.0 INTRODUCTION

A portion of I-25 just north of Denver was milled and overlaid in 1997. The hot mix

asphalt (HMA) placed on the job was a 19-mm Superpave 109 design gyration mix. The

binder met or exceeded all Colorado Department of Transportation (CDOT) PG 76-28

specifications. The 62,000-ton project received a Colorado Asphalt Pavement

Association (CAPA) award for quality in addition to bonuses for pavement smoothness

and quality materials.

In 1998, when the pavement was just one year old, both transverse and longitudinal

cracks began to appear. The cracks were originally thought to be due to reflective

cracking. The pavement continued to rapidly deteriorate and a forensic study was

undertaken in 2000.

Following completion of the forensic study by the study panel, it was discovered that the

longitudinal cracks on I-25 lined up perfectly with the paver screw and the two drive

chains on the paver that was used to pave I-25. It is believed that segregation occurred in

these locations and, mixed with other problems like low percent asphalt, contributed to

the longitudinal cracking.

One of the findings of the forensic team was that the actual percent asphalt in the

pavement was 0.5% lower than the percent asphalt reported by QC/QA testing. As a

result, the forensic team suggested that CDOT evaluate the various locations that are

permitted for sampling HMA to determine if some sampling locations give falsely high

or low percent asphalt content results.

This study was initiated in response to the forensic team’s recommendation to evaluate

the different sampling locations of hot mix asphalt to determine asphalt content.

CDOT currently allows for sampling at the plant, from a windrow, from the paver screw,

and from behind the paver both with and without a template. The purpose of this study

was to determine which of these sampling locations produced material properties that

2

were representative of those behind the paver. The objective of this study was only to

evaluate the impact that the sampling location of the hot mix asphalt had on the measured

asphalt content (%). This study did not take into consideration other mix characteristics

such as gradation, volumetric properties or mechanical properties.

The material used in this study was sampled from CDOT projects. Only grading S and

grading SX mixes were included in this study. Sampling was done per CP 41. (See

Appendix B)

2.0 SAMPLING (Colorado Procedure 41-98)

Asphalt mixtures were sampled in accordance with CP 41-98. Three different locations

were used to sample the mixture. Each location was sampled with two different methods.

It was important to understand how these different sampling methods influence the test

results. The locations and methods used are shown in Table 2.1. There was a total of 3

locations and 6 methods.

Table 2.1 Sampling Locations and Methods

Location Method

Positioning tube sampler before mix discharge

Asphalt plant

Swinging tube sampler through the mix discharge

From the windrow

Point of delivery

From the paver screws

Using a template

Behind the paver before compaction

Without using a template

Sampling correctly is as important as testing correctly. The samples must represent the

condition and the nature of the pavement. Two important considerations must be kept in

mind when sampling. First, avoid segregation. Second, prevent contamination of any

foreign matter on the sample.

3

After sampling was completed, material was split according to CP 55-97 (See Appendix

C) and tested to determine the asphalt binder content.

3.0 CP 41 SAMPLING BITUMINOUS PAVING MIXTURES

The following sampling locations and methods were used for this study.

3.1 Tube Sampler

Sampling at the plant is a convenient method to obtain samples. Often, a field laboratory

and a laboratory technician are located at the plant. This allows for a quick turnaround

time on quality control tests. The main disadvantage of this method is that the absorption

of asphalt into the aggregate may not be complete. This lack of absorption could affect

factors such as voids in mineral aggregate (VMA) and air voids, which are not being

measured by this study. It should be noted that Colorado Procedure-Laboratory 5115 has

time requirements to ensure absorption.

Samples obtained at the plant were taken from the hot-mix plant silo discharge chute.

Two methods were followed. Both methods required a tube sampler, tube sampler

holder, and a container having a tight fitting lid. These methods are

1. Swing Silo

During the discharge of mixture, swing the tube through the discharge stream.

2. Static Silo

Prior to the discharge, center the sampling tube directly under the discharge flow.

After the mixture has been discharged from the silo, return the tube holder to the storage

position away from the point of discharge. To avoid segregation, strike off any material

above the top rim of the tube sampler.

3.2 Point of Delivery

This location may provide a slow turnaround time due to transporting the sample from

the plant to the project (which might take from 30 minutes to two hours), transporting

4

samples from the project to the laboratory, and reheating the samples for testing.

However, absorption will occur during this time and the mix will better represent the mix

placed on the road.

A square ended shovel and a container with a tight fitting lid are required. In this

method, two different sampling procedures are followed.

1. Sampling from the windrow prior to laydown.

Three different locations are randomly selected. Material should be removed from

one side of the windrow for the full depth to expose a face. Using the square shovel,

trench the exposed face from bottom to top. Mixtures from all three locations are

placed into the container to obtain the required sample.

2. Sampling from paving screws.

While the paver is in motion and with the screws at least two-thirds covered with the

mixture, three increments of mixture are taken ahead of the paving screws.

3.3 Behind Paver

A square ended shovel and a container having a tight fitting lid, templates are optional.

In this method, two procedures are allowed. One uses a template and the other doesn’t

use a template. For either procedure, three different locations are randomly selected, and

sampled.

When using a template, place the templates in three different locations before the paver

arrives. These templates may have strings attached so the templates can be located after

the paver goes over them. The mix collected on the three templates is placed into the

container.

When not using a template, a full depth of material behind the paver should be taken

immediately. These samples should exclude any underlying material, such as tack coat,

and should be taken from three randomly selected locations.

5

4.0 CP 55 REDUCING FIELD SAMPLES (SELECTION BY CROSS

SECTION)

Samples were reduced for testing per CP 55, Method D.

In this method, a small, flat, square end scoop with square sides, a putty knife and two

slats having a height at least one inch taller than the sides of the splitting pan, are needed.

The mixture is placed into the pan per Method 2. In this method, the can containing the

sample is placed into the splitting pan with the opening of the can resting downwards on

the bottom of the pan. The can of mix is then lifted approximately one inch above the

splitting pan. The can of mix is moved in a circular motion, allowing the mix to trail out

of the can. The material should be placed into the splitting pan in not less than two

complete circular motions. If segregation is visible, the material should be turned over

onto itself using the scoop.

A sample is obtained by pushing a dividing slat vertically through the entire width of the

sample until it contacts the bottom of the pan. A second slat is placed parallel to the first

and pushed vertically to the bottom of the pan. All of the material between the slats is

removed, including the fines. Additional samples are obtained by pushing one of the

slats vertically into the remaining material and repeating the aforementioned process.

5.0 DETERMINATION OF THE ASPHALT CONTENT

(IGNITION METHOD)

The asphalt content (%) was determined using Colorado Procedure-Laboratory (CP-L)

5120. A sample of bituminous mixture was heated in an oven having a temperature of

538

o

C (1000

o

F) until the asphalt binder fraction was ignited and burned away. The

asphalt binder content was determined as follows:

100*

)(

)()(

initialm

finalminitialm

b

W

WW

P

−

=

6

Where

P

b

= Asphalt binder content, in percent, determined by the mass loss

measured on an external scale,

W

m(initial)

= External scale weight (mass) of the bituminous mixture specimen

before ignition, grams,

W

m(final)

= External scale weight (mass) of the bituminous mixture specimen after

ignition, grams.

A correction factor is normally applied to the burn-off results to obtain an accurate

asphalt content. No correction factor could be applied to any samples in this study. This

was not considered to be a problem as all samples were being compared, in an

uncorrected state, to the uncorrected value that was behind the paver, with a template.

The correction factor was likely the same regardless of sampling location.

7

6.0 RESULTS

Samples were taken from twenty-one different CDOT projects. On each project,

samples were collected from as many as three locations, with each location having up to

two methods. The locations for these methods were the plant (tube samplers), the point

of delivery, and behind the paver. Table 6.1 shows the asphalt content (%) collected

from different projects using all the above methods.

Table 6.1 %AC for All Samples Using All Methods

Method

Project #

Silo Silo Windrow

Paver Screws

Behind Paver

Behind Paver

Swing Static No Template

Template

2 0.00

0.00

5.71 5.85

5.63

5.73

3 0.00

0.00

5.83 5.54

5.41

5.58

4 4.81

5.05

0.00 4.35

4.87

5.08

5 4.96

4.94

0.00 5.01

4.96

5.06

6 0.00

0.00

0.00 5.55

4.95

4.90

7 0.00

0.00

0.00 5.14

5.12

5.01

8 0.00

0.00

0.00 5.18

5.25

5.26

9 0.00

0.00

0.00 5.21

5.34

5.35

10 0.00

0.00

0.00 6.57

6.19

6.09

11 0.00

0.00

0.00 6.16

5.61

5.79

12 5.37

5.25

0.00 5.31

5.05

5.42

13 5.16

5.77

0.00 5.39

5.40

5.39

14 5.45

5.62

0.00 5.54

5.43

5.11

16 5.05

5.17

0.00 5.02

4.97

5.13

17 4.98

5.14

0.00 5.02

4.86

5.11

18 0.00

0.00

0.00 6.26

6.20

6.21

19 0.00

0.00

0.00 6.43

6.15

6.32

20 0.00

0.00

0.00 4.65 4

.31

4.47

21 0.00

0.00

0.00 5.50

5.00

4.99

22 4.77

5.08

5.56 5.47

5.37

5.48

23 4.92

5.27

5.38 5.13

4.77

5.07

Note: Gray shading indicates the sampling method could not be used.

The data collected from behind the paver, using the template, was considered

representative of the pavement that will serve the road. All data from all other methods

were compared to the asphalt content (%) from the sample taken from behind the paver,

using templates. The ratios of the asphalt content (%) for all methods to the % AC using

8

templates are shown in Table A.1. The average of all ratios for each method was taken

utilizing Equation 6.1. The standard deviation (σ) was also calculated for each method

utilizing Equation 6.2. The coefficient of variation (COV), which expresses the

magnitude of the variability as a percentage of a fraction of the mean value, was

determined utilizing Equation 6.3. The COV must be less than 20% in order for the

method to be accepted as statistically similar to sampling from behind the paver with a

template.

−

x , σ, and COV for the ratio of each method are shown in Table 6.2.

(6.1) /

∑

=

−

Nxx

i

( )

(6.2) 1/

2

∑

−

−=

−

Nxx

i

σ

(6.3)

−

=

X

COV

σ

Table 6.2 The Average Ratio, 1- Average Ratio, the Standard Deviation, and the

Coefficient of Variation of Each Method

Silo swing Silo static Windrow

Screws Behind paver

w/ no template

−

x

0.9713 1.0099 1.0293 1.0154 0.9847

1−

−

x

0.0287 -0.0099 -0.0293 -0.0154 0.0153

σ

0.0508 0.0532 0.0291 0.0577 0.0301

COV

0.0523 0.0526 0.0283 0.0568 0.0306

Also, one may utilize the probability density charts to see the data distribution of each

method, as shown in Table A.2 and Figure A.2.

9

7.0 DISCUSSION OF RESULTS

All methods have a COV of less than 20% and, therefore, are statistically similar to

sampling from behind the paver with a template. Sampling from the windrow had the

lowest COV at 0.0283. Sampling from behind the paver had the second lowest COV at

0.0306. Sampling from the screws or from the silo all provided COVs greater than 0.05.

8.0 CONCLUSIONS

All sampling locations for determing the asphalt content used in this study produced

similar asphalt content test results and are considered acceptable.

9.0 RECOMMENDATIONS

The scope of this study was limited to determining the asphalt content of the mix placed.

This study did not investigate gradation, addition of lime, volumetric properties or

mechanical properties of the mix. Further evaluation needs to be conducted to determine

if the location of sampling has an effect on these mix characteristics.

Based on the results from this study no changes are needed to CP-41. CDOT should

continue sampling for asphalt content (%) using the current procedure. However, when

possible the material should be sampled from behind the paver for testing as this material

is the most representative of actual material in-place.

A-2

Appendix A

Results of % AC from All Locations

A-2

A. Results of % A.C. from All Locations

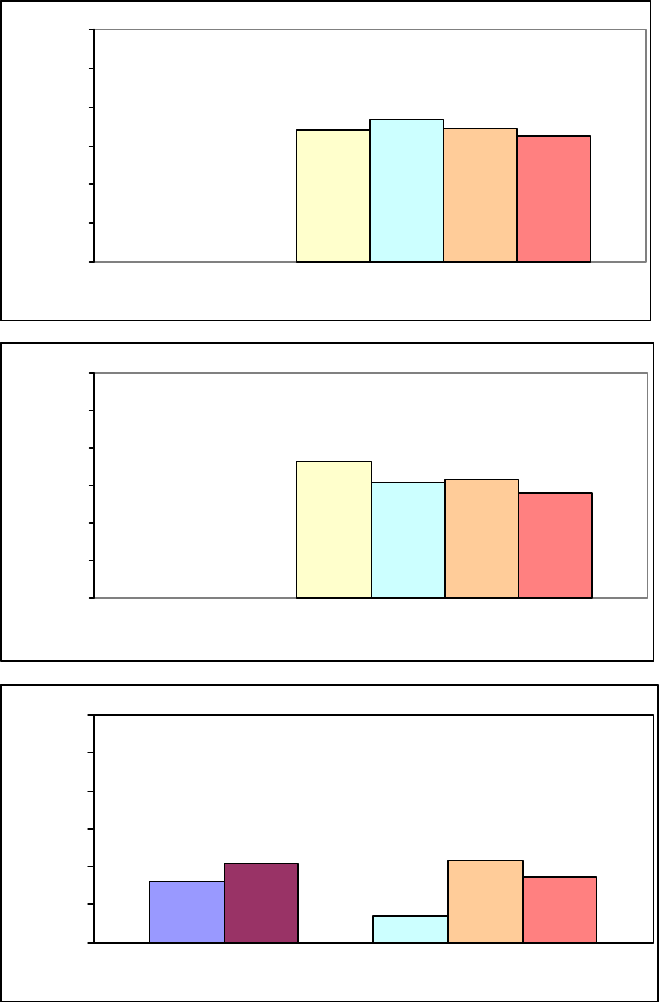

Figure A.1 % AC for Each Project Using All Methods

4.00

4.50

5.00

5.50

6.00

6.50

7.00

Project # 2

% A.C.

Paver screw

Windrow

Template

No template

4.00

4.50

5.00

5.50

6.00

6.50

7.00

Project # 3

% A.C.

Windrow

Paver screw

Template

No template

4.00

4.50

5.00

5.50

6.00

6.50

7.00

Project # 4

% A.C.

Silo swing

Silo static

Paver screw

Template

No template

A-3

4.00

4.50

5.00

5.50

6.00

6.50

7.00

Project # 5

% A.C.

Silo swing

Silo static

Paver screw

Template

No template

4.00

4.50

5.00

5.50

6.00

6.50

7.00

Project # 6

% A.C.

Paver screw

Template

No template

4.00

4.50

5.00

5.50

6.00

6.50

7.00

Project # 7

% A.C.

Paver screw

Template

No Template

A-4

4.00

4.50

5.00

5.50

6.00

6.50

7.00

Project # 8

% A.C.

Paver screw

Template

No Template

4.00

4.50

5.00

5.50

6.00

6.50

7.00

Project # 9

% A.C.

Paver screw

Template

No Template

4.00

4.50

5.00

5.50

6.00

6.50

7.00

Project # 10

% A.C.

Paver screw

Template

No template

A-5

4.00

4.50

5.00

5.50

6.00

6.50

7.00

Project # 11

% A.C.

Paver screw

Template

No template

4.00

4.50

5.00

5.50

6.00

6.50

7.00

Project # 12

% A.C.

Silo swing

Silo static

Paver screw

Template

No template

4.00

4.50

5.00

5.50

6.00

6.50

7.00

Project # 13

% A.C.

Silo swing

Silo static

Paver screw

Template

No template

A-6

4.00

4.50

5.00

5.50

6.00

6.50

7.00

Project # 14

% A.C.

Silo swing

Silo static

Paver screw

Template

No template

4.70

4.80

4.90

5.00

5.10

5.20

Project # 16

% A.C.

Silo swing

Silo static

Paver screw

Template

No template

4.00

4.50

5.00

5.50

6.00

6.50

7.00

Project # 17

% A.C.

Silo swing

Silo static

Paver screw

Template

No template

A-7

4.00

4.50

5.00

5.50

6.00

6.50

7.00

Project # 18

% A.C.

Paver screw

Template

No template

4.00

4.50

5.00

5.50

6.00

6.50

7.00

Project # 19

% A.C.

Paver screw

Template

No template

4.00

4.50

5.00

5.50

6.00

6.50

7.00

Project # 20

% A.C.

Paver screw

Template

No template

A-8

4.00

4.50

5.00

5.50

6.00

6.50

7.00

Project # 21

% A.C.

Paver screw

Template

No template

4

4.5

5

5.5

6

6.5

7

Project # 22

% A.C.

Silo swing

Silo static

Paver screw

Template

Windrow

No template

4

4.5

5

5.5

6

6.5

7

Project # 23

% A.C.

Silo swing

Silo static

Paver screw

Template

No template

Windrow

A-9

Table A.1 Ratio of % C of All Methods to the % AC of Samples Behind the Paver

with Template

Project #

RS

swing

RS

static

R

windrow

R

screws

R

no template

2

0.9965

1.0209

0.9825

3

1.0448

0.9928

0.9695

4 0.9469

0.9941

0.8563

0.9587

5 0.9802

0.9763

0.9901

0.9802

6 1.1327

1.0102

7 1.0259

1.0220

8 0.9848

0.9981

9 0.9738

0.9981

10 1.0788

1.0164

11 1.0639

0.9689

12 0.9908

0.9686

0.9797

0.9317

13 0.9573

1.0705

1.0000

1.0019

14 1.0665

1.0998

1.0841

1.0626

15

16 0.9844

1.0078

0.9786

0.9688

17 0.9746

1.0059

0.9824

0.9511

18 1.0081

0.9984

19 1.0174

0.9731

20 1.0403

0.9642

21 1.1022

1.0020

22 0.8704

0.9270

1.0146

0.9982

0.9799

23 0.9704

1.0394

1.0611

1.0118

0.9408

Average

0.9713 1.0099 1.0293 1.0154

0.9847

1-average 0.0287 -0.0099 -0.0293 -0.0154

0.0153

Standard deviation 0.0508 0.0532 0.0291 0.0577

0.0301

COV 0.0523 0.0526 0.0283 0.0568

0.0306

The shaded area means no data entry

RS

swing

= Silo swing / Behind paver with template

RS

static

= Silo static / Behind paver with template

Rscrews= Screws / Behind paver with template

R

windrow

= Windrow / Behind paver with template

R

no template

= Behind paver without template / Behind paver with template

( )

1/

/

2

−

−

−

=

−

−=

=

∑

∑

X

COV

Nxx

Nxx

i

i

σ

σ

valuesdata ofNumber N

variationoft coefficien The

deviation standard The

(average) mean value The

=

=

=

=

−

COV

x

σ

A-10

Table A.2 Probability Density of Each Method

RS

swing

Frequency

.85-.90 0

.901-.95

1

.951-1

7

1.001-1.05

0

1.051-1.1

1

1.101-1.15

0

RS

static

Frequency

.85-.90 0

.901-.95

1

.951-1

3

1.001-1.05

3

1.051-1.1

2

1.101-1.15

0

R

screws

Frequency

.85-.9 1

.901-.95

0

.951-1

9

1.001-1.05

6

1.051-1.1

3

1.101-1.15

2

1.151-1.2 0

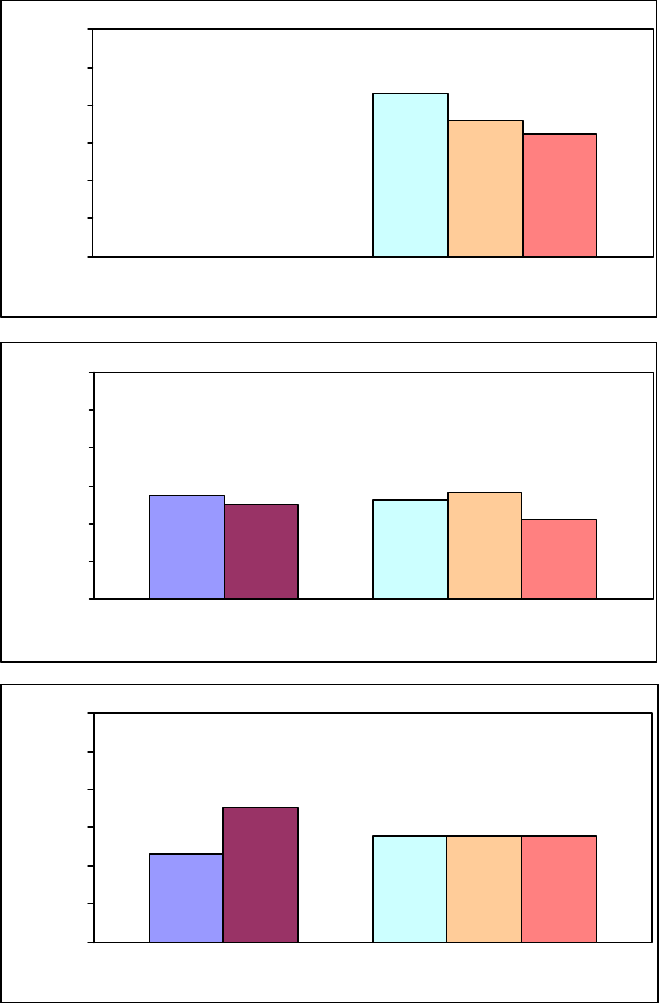

Figure A.2 Probability Density of Ratios in Each Method

R

no template

Frequency

.85-.9 0

.901-.95 2

.951-1 13

1.001-1.05

5

1.051-1.1

1

1.101-1.15

0

1.151-1.2 0

R

windrow

Frequency

.85-.9 0

.901-.95 0

.951-1 1

1.001-1.05

2

1.051-1.1

1

1.101-1.15

0

1.151-1.2 0

The percentage of the range between 0.95 - 1.05

67

75

86

78

71

Histogram of % AC of Silo Swing to % AC of Behind

the Paver (Template)

0

5

10

.85-.90 .901-.95 .951-1 1.001-

1.05

1.051-

1.1

1.101-

1.15

% A.C (Silo swing)/% A.C. (Template)

Frequency

A

-

11

Histogram of % AC of Silo Static To % AC of Behind the

Paver (Template)

0

2

4

.85-.90 .901-.95 .951-1 1.001-

1.05

1.051-1.1 1.101-

1.15

% A.C (Silo static)/% A.C. (Template)

Frequency

Histogram of % AC of Paver Screws to % AC of Behind

the Paver (Template)

0

5

10

.85-.9 .901-.95 .951-1 1.001-

1.05

1.051-

1.1

1.101-

1.15

1.151-

1.2

% A.C (screws)/% A.C. (Template)

Frequency

Histogram of % AC of Windrow to % AC of Behind the

Paver (Template)

0

1

2

3

.85-.9 .901-.95 .951-1 1.001-

1.05

1.051-

1.1

1.101-

1.15

1.151-

1.2

% A.C (windrow)/% A.C. (Template)

Frequency

Histogram of % AC of Behind the Paver (No

Template) to % AC of Behind the Paver (Template)

0

5

10

15

.85-.9 .901-

.95

.951-1 1.001-

1.05

1.051-

1.1

1.101-

1.15

1.151-

1.2

% A.C (No template)/% A.C. (Template)

Frequency

B

-

1

Appendix B

Colorado Procedure 41-98

Standard Method of Test for

Sampling Bituminous Paving Mixtures

B

-

2

Colorado Procedure 41-98

Standard Method of Test for

Sampling Bituminous Paving Mixtures

This procedure modifies AASHTO T 168-91, AASHTO T 168-91 may not be used in-place of this

procedure.

1. Scope

1.1 This procedure covers sampling of

bituminous paving mixtures at points of

manufacture, storage, or delivery.

1.1.1 Samples obtained by this procedure

may be used for acceptance and quality

control of bituminous paving mixtures.

1.2 This standard may involve

hazardous materials, operations, and

equipment. This standard does not purport

to address all of the safety problems

associated with its use. It is the

responsibility of the user of this standard to

establish appropriate safety and health

practices and determine the applicability of

regulatory limitations prior to use.

1.3 The values stated in acceptable

English units are to be regarded as the

standard. The values in parentheses are

provided for information purposes only.

2. Referenced Documents

2.1 Colorado Procedures:

CP 75 Stratified Random Sampling of

Materials

3. Significance and Use

3.1 General:

3.1.1 Sampling is equally as important as

the testing, and the sampler shall use every

precaution to obtain samples that will yield

an acceptable estimate of the nature and

conditions of the materials which they

represent.

3.1.2 Care shall be taken in sampling

to avoid segregation of the material

being sampled. Care shall be taken also

to prevent contamination by dust or

other foreign matter.

3.1.3 Samples to be used for acceptance

or assurance testing shall be taken by the

contractor or his representative. An

authorized representative of the Colorado

Department of Transportation shall be

present during the sampling procedure. The

CDOT Representative present shall take

immediate possession of all samples taken.

CDOT reserves the right to designate the

method and location of material to be

sampled.

4. Procedure

4.1 Sampling Equipment - The

contractor shall provide equipment needed

for safe and appropriate sampling.

4.2 Sample Handling - Combine all

sample increments. Place sample in a

suitable container having a tight fitting lid.

4.3 Sampling - The procedures for

selecting samples are described in CP 75.

The material shall be sampled using

stratified random sampling from all of the

material delivered to the job site.

METHOD A - TUBE SAMPLER

5. Apparatus

5.1 Tube sampler, with a minimum of 2-

7/8 in. (73 mm) inside diameter, 16 gauge

B

-

3

minimum thickness, length and diameter

variable with desired test specimen size.

5.2 Tube sampler holder with a metal

collar into which the sampler fits, with a 3 ft.

(1 m) handle or a tube sampler holder with

suitable arm arrangement to hold two tube

samplers which can be positioned directly

beneath the discharge opening.

5.3 Container, of suitable capacity and

having a tight fitting lid.

6. Procedure

6.1 Batch Plant and Storage Silos -

Insert one or two tube samplers into the

sampler holder arm while the arm is swung

away from the discharge. Obtain one or

more samples from the material being

loaded into a single truck using one of the

following methods: (1) during discharge of

mixture, swing the arm holding the tube(s)

through the discharge stream at a rate fast

enough to obtain a representative sample

filling the tube(s) (2) prior to the discharge,

center the sampling tube(s) directly under

the discharge flow. After the mixture has

been discharged, return the apparatus to the

storage position away from the point of

discharge and remove the tube(s). Strike off

any material above the top rim of the tube

sampler.

METHOD B - POINT OF DELIVERY

7. Apparatus

7.1 Small flat scoop with vertical sides

or square ended shovel.

7.2 Container, of suitable capacity and

having a tight fitting lid.

8. Procedure

8.1 Sampling from the Windrow Prior to

Laydown - Select three or more locations at

random from the windrow. Samples of the

windrow shall be secured at each location

by removing material from one side of the

windrow for the full depth to expose a face.

Using the flat scoop, or a square shovel with

sides, trench the exposed face from bottom

to top, taking care to avoid segregation of

particle sizes. Combine the samples from

the different locations to obtain the required

sample size as specified in Section 11.

8.2 Sampling from Paving Machine

Spreading Screws - While the paver is in

motion, observe the operation of the

spreading screws which transport the

mixture from the slat feeders to either side of

the paver. These screws should be

operating eighty percent or more of the time

and be at least two-thirds covered with the

mixture, if this is not the case, samples

taken from the screws may be segregated

and this method of sampling should not be

used.

8.2.1 If the conditions of 8.2 are met,

obtain at least three approximately equal

increments of mixture ahead of the

spreading screws which transport the

mixture from the slat feeders to either side of

the paver as follows: insert the flat scoop or

shovel into the mixture and remove the

portion with minimal loss of the larger

particles.

8.3 Sampling from a Conveyor Belt --

CDOT no longer utilizes this sampling

technique.

METHOD C - BEHIND PAVER

9. Apparatus

9.1 Small flat scoop, square ended

shovel with vertical sides, or sampling

device similar to Figure 41-1.

9.2 Container, of suitable capacity

having a tight fitting lid.

10. Procedure

10.1 Sampling from the Roadway Prior to

Compaction- Obtain at least three

approximately equal increments, at a

longitudinal location selected at random

using CP 75, and combine to form a field

sample whose quantity equals or exceeds

the minimum recommended in Section 11.

B

-

4

10.1.1 Take all increments from the

roadway immediately behind the machine

for the full depth of the material, taking care

to exclude any underlying material. Locate

the sampling position across the width of the

roadway using CP 75. When necessary,

place templates on the existing roadway to

exclude any underlying material. Clearly

mark the specified area from which each

increment or sample is to be removed.

Templates which are placed before the

mixture is spread will be a definite aid in

securing approximately equal increment

weights.

10.2 Sampling from Roadway after

Compaction - Select the areas to be

sampled using CP 75 from the material in

place. Obtain at least three approximately

equal increments selected from the area

being sampled. Take all increments from the

roadway for the full depth of the material,

taking care to exclude any underlying

material. Each increment shall be obtained

by coring, sawing, or other methods in such

a manner as to ensure a minimum

disturbance of the material.

11. Size of Sample

11.1 Number and Quantities of Field

Samples:

11.1.1 The number of field samples

required is specified in the Schedule for

Minimum Materials Sampling, Testing, and

Inspection contained in the CDOT Field

Materials Manual. The CDOT Field

Materials Manual specifies the quantities of

sample required for testing in the Central

Lab and the Region Lab. Project field tests

will require a minimum sample size of 30 lbs

(14 kg).

12. Shipping Samples

12.1 Transport samples in suitable

containers having a tight fitting lid, so

constructed as to preclude loss or

contamination of any part of the sample, or

damage to the contents from mishandling

during shipment.

12.2 Samples shall have individual

identification attached giving the information

required by the sample user. Utilization of

CDOT Form # 633, Sample Tag (Sacks), is

required for all submitted samples. This

information is included in CDOT Form # 157

and a sample form is shown in Chapter 400

of the CDOT Materials Manual.

C

-

1

Appendix C

Colorado Procedure 55-97

Standard Method of Test for

Reducing Field Samples of Hot Bituminous Pavements to Testing Size

C

-

2

Colorado Procedure 55-97

Standard Method of Test for

Reducing Field Samples of Hot Bituminous Pavements to Testing Size

This procedure modifies AASHTO T 248-89, AASHTO T 248-89 may not be used in place of this procedure.

1. SCOPE

1.1 These methods cover the reduction

of field samples of hot bituminous

pavements (HBP), having a nominal

maximum size equal to or less than 1.5 in.

(37.5 mm), to the appropriate size for

testing, employing techniques that are

intended to minimize variations in measured

characteristics between the test samples so

selected and the field sample.

1.2 The values stated in English units

are to be regarded as the standard.

2. REFERENCED DOCUMENTS

2.3 Colorado Procedures:

CP 41 Sampling Bituminous

Paving Mixtures

3. SIGNIFICANCE AND USE

3.1.1 The necessity for selecting

representative samples and reducing them

to test specimen size is emphasized in many

test procedures. Using the proper

equipment for the type of material to be

reduced in size is important. However,

unless used correctly, the final test

specimen will not necessarily be

representative of the total sample.

3.1.2 Specifications for HBP require

sampling portions of the material for testing.

Other factors being equal, larger samples

will tend to be more representative of the

total supply. These methods provide for

reducing the large sample obtained in the

field to a convenient size for conducting a

number of tests to describe the material.

The reduction is done in a manner such that

the smaller portion is most likely to be a

representation of the field sample, and thus

of the total supply. The individual test

methods provide for minimum weights of

material to be tested.

4. SAMPLING

4.1 The field sample of HBP shall be

taken in accordance with CP 41, or as

required by individual test methods. The

user shall satisfy himself that the initial size

of the field sample is adequate to

accomplish all intended tests.

4.2 Before sample reduction, the field

sample of HBP should be heated just until a

temperature which allows for the easy

separation of particles is attained. HBP

samples should not be reheated more than

necessary to separate particles.

5. SAMPLE PREPARATION

HBP samples shall be prepared for the

reduction required for Methods A, B, or D by

using either method 1 or 2.

5.1 Method 1

5.1.1 APPARATUS

5.1.2 Apparatus shall consist of a small,

flat, square end scoop with sides and a large

flat-bottomed mixing pan.

5.1.3 PROCEDURE

5.1.4 Place the field sample of HBP into

the mixing pan where there will be neither

loss of material nor the accidental addition of

foreign material. Mix the material thoroughly

by turning the entire sample over three

times. Flatten the sample in the pan to a

uniform depth, which should be the same or

lower than the sides of the scoop.

C

-

3

5.2 Method 2

5.2.1 APPARATUS

5.2.2 Apparatus shall consist of a small,

flat, square end scoop with sides and a large

flat-bottomed mixing pan.

5.2.3 PROCEDURE

5.2.4 Place the can containing the field

sample of HBP into the mixing pan with the

opening of the can resting downwards on

the bottom of the pan. Elevate the can

approximately 1 inch above the pan bottom.

Move the can in a circular motion allowing a

thin, uniform layer to form a trail behind the

can. Try to distribute the material into two or

more layers. If visible areas of segregation

exist, mix the material thoroughly by turning

the entire sample over onto itself using the

scoop.

METHOD A - SELECTION BY SCOOP

6. APPARATUS

6.1 Apparatus shall consist of a small,

flat, square end scoop with sides and a putty

knife.

7. PROCEDURE

7.1 Prepare the sample for reduction

per Section 5.1 or Section 5.2

7.2 Obtain a sample for each test by

selecting at least three increments of

material at random locations, using a small,

flat, square end scoop. Insert the scoop to

the full depth of the material. Every attempt

should be made to minimize the loss of

particles, especially large aggregate

particles, over the sides of the scoop. A

putty knife may be used to separate the

material in the scoop from the material in the

pan and also to cut increments of material

from the main body of material in the scoop.

Do not shake the material in the scoop to

add small, additional amounts of material to

the specimen, as this may introduce

segregated material to the specimen.

Combine the portions to obtain a test

specimen having the required weight. Save

the remaining portion of the sample until

tests are completed.

METHOD B - QUARTERING

8. APPARATUS

8.1 Apparatus shall consist of a small,

flat, square end scoop with sides and a putty

knife.

9. PROCEDURE

9.1 Prepare the sample for reduction

per Section 5.1 or Section 5.2

9.2 Divide the mixture into four equal

quarters with a square scoop and remove

two diagonally opposite quarters, including

all fine material. Successively mix and

quarter the remaining material until the

sample is reduced to the desired size. Save

the remaining portion of the sample until

tests are completed.

METHOD C -MECHANICAL SPLITTER

10. APPARATUS

10.1 Sample Splitter - Sample splitters

shall have an even number of equal width

chutes, but not less than a total of eight for

coarse aggregate, or twelve for

fine-aggregate, which discharge alternatively

to each side of the splitter. For HBP

samples, the minimum width of the

individual chutes shall be approximately 50

percent larger than the largest particles in

the sample to be split (Note 1). The splitter

shall be equipped with a minimum of two

collection pans, having a width equal to or

slightly less than the overall assembly of

chutes in the splitter to hold the two halves

of the sample following splitting. It shall also

be equipped with a hopper, a flat scoop,

putty knife or straight-edged pan which has

a width equal to or slightly less than the

overall width of the assembly of chutes, by

which the sample may be fed at a controlled

rate to the chutes. The splitter and

accessory equipment shall be so designed

that the sample will flow smoothly without

C

-

4

restriction or loss of material. A splitter

brush should be used to clean the chutes of

adhering fines.

NOTE 1 - Mechanical splitters are

commonly available in sizes adequate for

coarse aggregate having the largest particle

not over 1 1/2 in. (37.5 mm).

11. PROCEDURE

11.1 The riffle splitter must be clean and

dry before use. Place the material into a

large, flat bottomed mixing pan. Mix the

material thoroughly. Using a flat scoop

equal in width to the overall length of the

riffles, remove material from the pan and

slowly pour the material into the riffle splitter

first from one side and then the other.

Alternatively, use a flat, square end scoop to

load the sample from the mixing pan into

two extra splitter pans placed side by side.

Slowly pour approximately half of the

sample in the pan from one side and then

reverse the ends of the pan and pour the

remainder from the other side. A slight

jarring action by the pan against the splitter

helps keep the riffles from clogging.

Uniformly distribute the sample from edge to

edge, so that when it is introduced into the

chutes, approximately equal amounts will

flow through each chute. The rate at which

the sample is introduced shall be such as to

allow a free flow through the chutes into the

receptacles below. Do not allow any of the

riffles to become plugged since this will

divert material to the two adjacent riffles and

send too much material to the opposite

receiving pan.

11.2 Reintroduce the portion of the

sample from alternating receptacles into the

splitter as many times as necessary to

reduce the sample to the size specified for

the intended test. Retain the portion of the

material collected in the other receptacle at

the last split until tests are completed.

NOTE 2 - As an alternative to Section 11.2,

further splitting to testing size can be

achieved with Section 11.3.

11.3 After splitting the material into two or

four equal measures (depending on the size

of the field sample), leave the divided

sample in the splitter pans and place in the

oven. Use the flat, square end scoop to

obtain individual test samples of the required

weight. Work from one end of the pan to the

other. Insert the scoop to the full depth of

the material. Every attempt should be made

to minimize the loss of particles over the

sides of the scoop. A putty knife may be

used to separate the material in the scoop

from the material in the pan and also to cut

increments from the main body of material in

the scoop. Do not shake the material in the

scoop to add small, additional amounts to

the specimen, as this may introduce

segregated material to the specimen. Save

the remaining portion of the sample until

tests are completed.

METHOD D -

SELECTION BY CROSS SECTION

12. APPARATUS

12.1 Apparatus shall consist of a small,

flat, square end scoop with square sides; a

putty knife; and two slats having a height at

least one inch taller than the sides of the

splitting pan. The slats shall conform within

one inch to the sides of the pan, so that

material can not fall from the vertical face

into the sample being separated.

13. PROCEDURE

13.1 Prepare the sample for reduction

per Section 5.1 or Section 5.2.

13.2 Obtain a sample for each test by

pushing a dividing slat vertically through the

entire width of the sample until it contacts

the bottom of the pan. Next, place a second

slat parallel to the first and push it vertically

to the bottom of the pan. Remove all of the

material between the slats. Take care to

include all fines from the pan, the slat sides,

and the utensil in the sample. Obtain

additional samples by pushing one of the

slats vertically into the remaining material

and repeating the process. Save the

remaining portion of the sample until tests

are completed.

C

-

5

METHOD E -

QUARTERMASTER MECHANICAL

SPLITTER

14. APPARATUS

14.1 Apparatus shall consist of a

Quartermaster mechanical splitter and a

spatula.

15. PROCEDURE

15.1 This procedure may be used for

combining and splitting large samples for

testing between two labs.

15.2 Close the hopper doors. Place the

HBP material into the hopper and level it out

with a spatula. Place 4 empty buckets tightly

in each corner with the handles facing

outward, away from the splitter. Turn the

Quartermaster handle to the left.

15.3 For further reductions in sample

size, choose two opposite corner containers

and repeat Section 15.2