www.mottcorp.com

1

Mott Corporation

SINTERED POROUS METAL FILTRATION SYSTEMS FOR

PETROLEUM REFINING APPLICATIONS

Dr. Kenn

eth L. Rubow

Louise L. Stange

Mott Corporation

Presented at the

A

merican

F

iltration and Separation Society Conference

Galveston, TX

April 9

-

12, 2002

www.mottcorp.com

2

Mott Corporation

S

INTERED POROUS METAL

FILTRATION SYSTEMS

FOR

PETROLEUM REFINING A

PPLICATIONS

Abstract:

Currently, petroleum products are the largest source of energy used in United

States, with 90 percent of these products being fuels such as gasoline, coke, kerosene

,

aviation fuels, distillate, residual oil and liquefied petroleum gas. Refineries convert

petroleum oil into finished products through physical, thermal and chemical separation

processes. Other materials produced by refineries include non

-

fuel petrochemi

cal

products such as ethylene, propylene and benzene used to manufacture chemicals and

plastics.

Stringent environmental regulations, safety concerns and productivity improvements

often necessitate modifying existing refinery and petrochemical processing

technology.

Reformulation of gasoline to reduce auto emissions and EPA regulations concerning the

handling of spent FCC catalyst have encouraged refineries to evaluate their catalyst

management strategy. Advances in filtration technology and filter media s

upport

improvements in catalyst recovery applications which improve overall product yield,

increase the market value of the filtered product, reduce wear and tear of downstream

equipment and minimize operator exposure to hazardous materials. This paper wil

l

discuss filter

-

operating parameters of sintered porous metal media and filtration system

design criteria for optimizing performance in the removal of catalyst fines from slurry oil.

INTRODUCTION

Petroleum refiners use a process called Fluid Catalytic

Cracking (FCC) to convert heavy

petroleum fractions into products such as gasoline, kerosene and feedstock for

petrochemical processes. The conversion of crude oil fractions into higher value

products requires the use of catalysts. The product stream from

the FCC unit contains

silica and alumina fines generated from catalysts used in the process. After distillation,

these fines are concentrated in the heaviest fraction or slurry oil.

Filtration systems designed for the removal of catalyst fines from slur

ry oil utilizing

sintered porous metal media were introduced in the mid 1980’s. Filtration of slurry oil

using an advanced filtration system design and sintered metal media continue to

demonstrate long term filter operating performance in the separation of

FCC catalyst

fines from slurry oil to reduce the ash content. Unlike centrifuges or electrostatic

techniques, the filtration media acts as a positive barrier to remove downstream catalyst

contamination

.

Sintered metal filtration technology using inside

-

ou

t filtration

configuration provides a reliable method of achieving high quality slurry oil product by

reducing catalyst content

.

1

The

backwash capability of the media provides an economic

alternative to the use of settling tanks. Removal of the fines incre

ases FCC product

yield, improves the market value of the filtered product and reduces wear and tear of

downstream equipment in addition to improving the catalyst recover and handling

process.

www.mottcorp.com

3

Mott Corporation

There are numerous grades and manufacturers of catalyst since

FCC was introduced in

the early 1940’s. Filtration feasibility testing continues to be an effective means in media

selection and verification of filter operating parameters to confirm process scale

-

up

design for commercial installations. Feasibility testin

g is recommended as catalyst fines

vary in size, with a range from submicron to 30

-

40 microns, and occasionally larger.

PRINCIPLE FEATURES A

ND PROPERTIES OF SIN

TERED METAL MEDIA

The primary characteristics of sintered metal media that make it well sui

ted for refinery

applications are strength, durability and pressure capacity. The inherent durability of

metal filters allows for continuous, backwash operation for extended periods. Sintered

metal media are manufactured by pressing pre

-

alloyed powders eit

her as tubes or as

porous sheet, followed by high temperature sintering. The combination of powder size,

pressing and sintering conditions defines the pore size and distribution, strength and

permeability of the porous element. The filter media is designed

and engineered with a

stable porous matrix, precise bubble point specification, close thickness tolerance and

uniformity of permeability, which assure reliable filtration performance, effective

backwash cleaning and long on

-

stream service life.

Pore size

of sintered metal media is determined using ASTM E

-

128 standard procedure

that relates pore size to the pressure required to expel a liquid from a capillary of a

certain diameter by gas. The media grade designation is equivalent to the mean flow

pore, or

average pore size of the filter. Sintered metal media are offered in grades 0.1,

0.2, 0.5, 1, 2, 5, 10, 20, 40 and 100.

Typically, 316L stainless steel grades 0.5 and 2 media are recommended for refinery

applications. The all

-

welded construction of porou

s media to hardware is an additional

advantage for high temperature and the abrasive nature of the slurry oil. Other corrosion

resistant alloys include: Stainless Steel 304 L, 310, 347, and 430; Hastelloy

®

2

B, B

-

2, C

-

22, C276, N and X; Inconel

®

600, 625, a

nd 690; Monel

®

400

3

; Nickel 200; Alloy 20;

Titanium.

www.mottcorp.com

4

Mott Corporation

Filter Media Selection for Removal of FCC Catalyst Fines

Due to variations in slurry oil viscosity, catalyst particle size and slurry concentration of

each refinery process the preferred method of se

lecting filter media is via laboratory or

pilot trials. Feasibility tests verify filter

-

operating parameters such as particle removal

efficiency, pressure drop vs. solids loading, recovery pressure after backwash and cycle

length. Experience in similar ser

vice may be the basis for filter selection, taking into

account the specific solids and liquid of the process and if actual test data cannot be

obtained.

The particle size range of catalyst material varies with the operating performance of the

FCC unit.

FCC catalysts are broadly classified on the basis of the method of

manufacture: silica or clay based and active alumina. The mechanical integrity of the

catalyst combined with cyclone efficiency influence solids concentration and catalyst

particle size dis

tribution of the slurry oil. Optimum filtration results are obtained with a

broad particle size distribution.

Cyclones are the first stage of catalyst fines removal in the FCC unit. Efficiently

operating cyclones can remove sufficient fines from the react

ion product to produce

slurry oil with solids content of about 0.2% by weight (2000 ppm) or lower.

4

Slurry oil

concentration evaluated in laboratory and pilot tests is typically between 500

-

1500 parts

per million (ppm) total suspended solids (TSS).

The

variations of the FCC catalyst

fines distribution are shown in

Figure 1. Normal catalyst fines

particle size distribution observed in

FCC cyclones is typically a normal

bell curve ranging from < 5 to 80

µm, with a peak in the 30

–

40 µm

range. Bimodal dis

tributions are the

result of either attrition of the

catalyst or damage to the cyclone or

plenum.

Attrition of the catalyst causes the

curve to shift to the left, with a peak

in the 2

–

3 µm range. Fracturing

catalyst at a high velocity stream

generates

submicron particles. A

shift to the right of the normal bell

shaped curve with a peak in the range

of 40 µm or greater is the result of full

-

range catalyst being drawn into the cyclone or plenum.

5

0

20

40

60

80

100

0

5

10

15

20

25

FCC Catalyst Fines Distribution

Wt. %

Particle Size, µm

Normal Distribution

Attrition

Damaged Cyclone

Figure 1. FCC catalyst fines distribution

www.mottcorp.com

5

Mott Corporation

Catalyst with a small mean particle size and narrow distr

ibution will usually require a

finer media grade and will filter more slowly. A larger mean particle size and broader

distribution will work with a coarser media grade at a slightly higher operating flux.

Sintered metal

media grades 0.5 and 2 are typica

lly recommended for refinery

applications. For applications with a catalyst particle size distribution that tends to shift

to the left of the normal distribution, grade 0.5 media ensures that the catalyst particles

are removed on the media surface preventi

ng media plugging and ensuring removal

efficiency.

Refineries have recognized improvements in filtration technology using sintered metal

cartridge filters for catalyst removal. Filtration evaluation of slurry oil streams from more

than 50 refinery locat

ions continue to show significant variation in catalyst particle and

distribution range. Samples evaluated to date have an average particle size range of

1

-

40 µm, with a mean size (based on volume %) of 15 µm. Laboratory and pilot testing

continues to b

e a reliable means to validate filter operating performance.

Table 1 summarizes several pilot studies conducted to evaluate filtrate quality using

grades 0.5, 2 and 5 media. Testing with grade 0.5 media and fine catalyst of less than

10 µm in size resul

ted in filtrate quality (based on ash analysis) of less than 20 ppm

TSS. Other refineries with larger catalyst fines have achieved similar filtrate quality with

grade 2 media. Tests using grade 5 media had the highest ash content measuring 91

ppm TSS.

F

iltration Principle

Sintered metal filters are high efficiency, two

-

dimensional, straining type with particulate

being collected on the media surface. The proper selection of media grade must

balance the needs of the filtration application regarding parti

cle retention, pressure drop

and backwash ability. There are basically three process factors to consider: fluid

velocity through the filter media, fluid viscosity and particle characteristics. The

important particle characteristics are particle shape, size

and density. Particles that are

hard, regular shaped and form incompressible cakes such as FCC catalyst are well

suited for surface filtration.

6

Table

1

. Pilot filtration testing using Mott grades 0.5, 2 and 5 media.

Feed Conc.

,

TSS, ppm

Particle Size

Range, µm

Avg. Particle

Size, µm

Media

Grade

Filtrate,

TSS, ppm

Operating

Flux,

gpm/ft

2

1000

N/A

< 10

0.5

< 20

N/A

750

-

1000

N/A

10

-

12

2

10

0.25

500

-

1000

1

-

30

20

2

10

-

15

0.1

-

0.5

1200

1

-

190

30

5

91

0.5

1500

1

-

190

30

0.5

10

0.34

Filtration operation is based on constant flow, increasing pressure drop until the terminal

pressure drop is reached. Terminal conditions will be reached when the catalyst cake

www.mottcorp.com

6

Mott Corporation

thickness increases to a point where the fluid flow pressure drop is a

t a maximum for a

given flow and viscosity condition. The filter is then backwashed by pressurizing the

filter with gas, then quickly opening the backwash discharge valve. This backwash

procedure generates a momentary high reverse differential pressure, wh

ich effectively

removes solids from the media surface. Reverse flows of clean liquid (filtrate) through

the media assists in the removal of solids and flushes them out of the filter.

The uniformity in the pressure drop over time for repeated cycles in fi

ltration operations

using sintered metal media is shown in Figure 2. Uniformity in the rate of rise of the

pressure drop indicates the feed slurry particle size distribution remains constant, as

does the slurry concentration. The inside

-

out filter configu

ration, utilizing filtration media

with uniform porosity, builds a uniform cake on the inside surface of the filter element

that improves particulate removal and backwash efficiency. Recovery pressure after

backwash increases slightly once media is conditi

oned, but should be within 2

-

3 PSI of

the clean flow pressure drop. Filter media recovery pressure drop must be stable for

consistent performance. Proper backwash methods and procedures must be followed

for good media cleaning. Changes in the slurry oil te

mperature will increase viscosity

and rate of rise pressure drop across the media, therefore design

-

operating

temperatures should be maintained throughout filtration process.

Figure 2. Press

ure profile for multiple cycles using Mott grade 0.5 media

0

60

0

2

4

6

8

10

TIME (hrs)

PRESSURE DROP (

psi)

TERMINAL PRESSURE DROP

CLEAN PRESSURE DROP

CONDITIONED ELEMENTS

CLEAN PRESSURE DROP

NEW ELEMENTS

www.mottcorp.com

7

Mott Corporation

FILTER SYSTEM DESCRI

PTION AND OPERATION

The inside

-

out filter housing configu

ration (Mott Hypulse

®

LSI

7

) allows solids to be

introduced to the filter on the inside surface of the tubular filter element. The filtration

unit consists of the vessel shell, a welded

-

in tube sheet, filter elements that are

threaded into the tubesheet an

d a spider plate that secures the top of the element

bundle. Figure 3 shows the filtration unit during forward flow. Standard design uses

cartridges fabricated from rolled and welded sheet to a 2 inch diameter x 70 inch overall

length filter element which

provides the highest filtration area for housing diameters

greater than 16 inches, with the minimum backwash volume per ft

2

filter area. 2”

diameter elements require filter cakes to be less than 0.5 inch thick. Collapse and burst

ratings of the 2 inch di

ameter filter elements are listed in Table 2.

Backwash procedure can be modified to suit

the process requirements. The design allows

for two basic options: Full shell (gas over liquid

backwash) and empty (drained) shell

backwash for maximum yields.

8

Each

backwash mode offers the capability to use a

different backwash liquid other than filtered

slurry. Options include light cycle or heavy

cycle oil. The choice depends on the need to

clean the elements and where the backwash is

sent for disposal.

The

strong, corrosion resistant and permanent

filtration media allows for continuous and safe

operation of filter systems in the refinery

industry. Maintainence on the filters for normal

routine operations is minimal. Elements can

be cleaned in place or remo

ved from service

for commercial cleaning to remove tars and

gums. Use of back

-

washable sintered metal

filters enables the design of filtration systems

with the least amount of moving parts and

minimizes operator exposure to hazardous

materials. These filte

r systems are operated and controlled remotely and can be

integrated with the control system of the plant.

Table

2

. Element collapse and burst pressure of 2 inch diameter cartridges.

Media Grade

Collapse Pressure, PSID

Burst Pres

sure, PSI

0.5

107

503

2.0

180

420

Figure 3. Inside

-

out filter configuration

www.mottcorp.com

8

Mott Corporation

Filter Design Specifications

Filter housings are ASME coded pressure vessels built according to requirements of the

process, with standard filter systems of 24, 36 and 42

-

inch diameter housings. Table 3

describes filt

er design considerations such as filtration area, backwash volume and

barrels per day capacity. The 36” and 42” systems are single vessel installations

operating on a continuous basis with interruptible flow. The 24” system is a triple filter

system operat

ing on a continuous basis as shown in Figure 4. One filter operates on

-

line, one is on stand

-

by, and one is a spare used during maintenance periods. The

unique design incorporates inside

-

out flow through the filter elements for increased

pressure drop cap

ability, reduced filter complexity and operational flexibility. Standard

design is 600°F at 300 psi with 100 psi differential pressure.

Figure 4. FCC Filter System Schematic

Table

3

. Filter Design Parameters (Standard 2” OD x 70

” length elements).

Housing

Diameter,

Inches

Number

of

Elements

Filtration

Area, ft

2

Backwash

Volume

Full Shell, Gal

Backwash

Volume

Empty Shell,

Gal

Max.

Capacity,

BPD*

24

61

174

150

70

3600

36

151

432

380

180

8900

42

199

570

564

261

11,700

*Maxim

um capacity barrels per day (BPD) based on flux rate of 0.6 gpm/ft

2

.

www.mottcorp.com

9

Mott Corporation

0

10

20

30

37

40

0

5

10

15

20

25

30

35

40

45

Pressure Profile Slurry Oil Filtation

Mott HyPulse LSI Filter

Media Grade 2 @ 0.5 gpm/ft

2

Filter Operating Pressure, PSI

Cycle Time, Minutes

1 Day

4 Days

30 Days

APPLICATIONS

Backwash Filter Performance: Case Study 1

Pilot studies at a commercial refinery used a 10

GPM (340 BPD) automated pilot filter

(Figure 5) to verify filter operating perf

ormance and media selection in tests conducted

during a two

-

month trial. The filter was cycled continuously between filtration and

backwash, with more than 2500 cycles performed. Backwash liquid was intermediate

cycle gas oil. Tests were conducted to maxi

mize the number of cycles during the test

period.

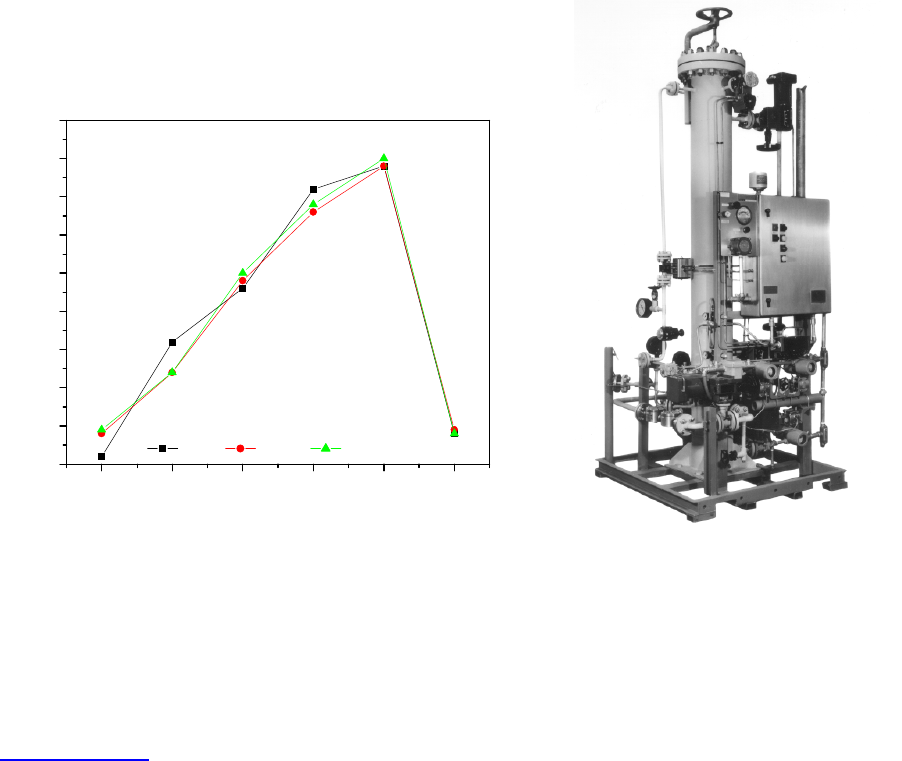

Figure 6 shows a uniform pressure profile comparing the rate of rise in pressure drop

over time of grade 2 media after 1, 4 and 30 days. Slurry oil concentration ranged from

500

-

1000 PPM. Average particle

size was about 20 µm. The filtration cycle was about

40 minutes with terminal pressures of 37

-

40 PSI. Recovery pressure after backwash

ranged from 2

-

5 PSI. Filtrate quality was less than 25 PPM TSS with most cycles < 10

ppm or less.

Increase in solid

s concentration will shorten cycle time as pressure drop increases at a

faster rate. This effect can be overcome somewhat by increasing the cycle terminal

pressure drop. If the increased solids concentration is due to the addition of large

particles increa

sed solids cake permeability may

result, which will increase the solids loading capacity

at the same pressure drop.

Figure 6. Pressure profile comparison

Figure 5. Automated Filter

www.mottcorp.com

10

Mott Corporation

Table

4

. Filtration cycle time and backwash sequence

Backwash Sequence Description

Cycle Time

Filter forwar

d flow to 60 PSID

80 minutes

Drain Filtrate Shell

1.5 minutes

Fill with LCO

1.5 min

Pressurize

0.25 minutes

Backwash and Drain

0.25 minutes

Total Time

83.5 minutes

Filter Operating Efficiency: Case Study 2

Online and throughput efficiency of

backwashable sintered metal filter were evaluated

using both full shell and empty (drained) shell backwash methods using an automated

filter system. The filtration unit consists of 24” diameter filter housing with standard 2”

diameter elements, having a to

tal filtration area of 174 ft

2

. Filter operation parameters

were 40 GPM with solids load to filter of 0.75#/min. Filter design operating flux is 0.23

gpm/ft

2

. The filter cycle time and backwash sequence is described in Table 4.

Filter efficiency is also

measured as throughput efficiency, or amount of product

processed as filtrate compared to the amount of product or feed delivered to the filter.

This is defined as:

E

T

=(V

FIL

/ V

FD

) x 100%

Where: E

T

= efficiency of liquid recovery

V

FIL

= volume

of filtrate recovered

V

FD

= volume of feed to the filter

Online efficiency is measured as forward flow cycle time divided by entire filtration cycle

time (including backwash) or 80/83.5 x 100 = 95.8% efficiency.

The filtration unit is designed to minimi

ze loss of product, which consists primarily of the

backwash and recovered solids. Throughput efficiency comparing full shell and drained

shell backwash is described in Table 5. The total volume processed (40 GPM x 80

minutes) was 3200 gallons.

Table

5

. Throughput Efficiency

Full Shell

Drained Shell

Backwash Volume, gallons

150

70

(V

FIL

/ V

FD

)

3050/3200

3130/3200

Throughput Efficiency

95 %

98%

www.mottcorp.com

11

Mott Corporation

Figure 7. Schematic of triple filter system

Filter Operating Experience

–

Commercial Installations

In 1985, the first cont

inuous use of a sintered metal filter using inside

-

out (LSI)

HyPulse

®

filtration technology developed by Mott Corporation demonstrated the

suitability of sintered metal media for high temperature filtration of slurry oil for a carbon

fiber development proc

ess. Slurry oil came from tankage where large particles had

settled and oil had cooled to 350°F, increasing the viscosity to 9 cp. The filter operated

reliably for many years producing clean oil with solids content of less than 20 ppm. The

filter was even

tually shut down because of low product demand.

Since then, refineries around the world have become aware of the benefits of filtration

using sintered metal media for catalyst fines removal in slurry oil service. The largest

systems to date are located i

n the United States and China.

Throughout the 1990’s numerous LSI filtration systems have been installed for FCC

slurry oil filtration at numerous refineries worldwide the largest employing (3) 66” LSI

filters. A schematic of a triple filter system is sh

own in Figure 7. Filtration cycle time

ranges from 2 to 16 hours operating at 30 & 60 PSI, respectively in the filtration of 1000

ppm slurry oil. Extended cycle times were obtained by running two filters

simultaneously, but staggered in cycle time, with th

e third being on stand

-

by for

utilization when one of the other filter units is backwashed. The filter design uses a full

shell backwash. Efficiency of the recovered product using two filters on line exceeds

99.8%

9

.

Since 1997, several refineries in Chi

na

have installed LSI filtration systems for

catalyst removal in resid fluid catalytic

cracking (RFCC) units. A filtration

system with (2) 24” LSI filters was

installed in a RFCC unit with 1.4 million

metric tons (mt) per year capacity and an

output of sl

urry oil of 180 mt/day. The

filter is controlled by local PLC that

communicates with refineries distributed

control system (DCS) to enable the

operator monitor the filtration in the

control room. The slurry oil has an

average 3,000

-

5,000 ppm solids

concent

ration. Cycle time varies from 2

-

8

hours. The filtrate solids content is under

50 ppm. The system is running

continuously since then supplying a local company with clean filtrate to produce carbon

black.

Another unit has 1.2

-

million mt/year capacity but on

ly has about 75

-

mt/day slurry oil

output. The system utilizes (3) 20” LSI filters controlled by local PLC. Each filtration unit

is capable of handling entire flow, or two filters can run simultaneously to optimize

www.mottcorp.com

12

Mott Corporation

product yield. The unit operates mostly du

ring the winter months to supply the clean

slurry oil to replace fresh crude as fuel oil for heating in the oilfield and local residential

area. Average slurry oil concentration is 4,000

-

6,000 ppm, and is occasionally over

10,000 ppm under unstable conditi

ons. Cycle time varies from 30 minutes to 4 hours

depends on the operating conditions and solids concentration.

SUMMARY

Sintered metal media has demonstrated its suitablity in a highly efficient catalyst

removal filter system for slurry oil service. Com

mercial FCC installations using grades

0.5 and 2 media are capable of producing quality clean oil product with suspended

solids content of less than 20 PPM. Filtrate quality of RFCC is typically about 50 ppm.

Filtration offers a slurry stream of higher pr

oduct value that can be used as a clean fuel

blend component, feed stock for needle coke or high

-

grade carbon black slurry oil

stream.

Filtration utilizing a unique housing configuration that allows feed to be fed to the inside

of the filter cartridge op

timizes both operating efficency and backwash efficiency of the

filter.

Proper media selection, along with filtering within specified operating parameters,

provides product recovery up to 99.8% efficiency. The inside

-

out filter configuration

minimizes back

wash volume that is either recycled back to the reactor or handled as a

waste product. Backwash volume is 0.5 to 1 gal/ft

2

, depending on whether filtrate is

drained from the shell or used as backwash. On a capacity basis, for 1000 BPD

processed, 20

-

50 BPD

go back to the reactor as backwash. This is a low rate in

comparison to other types of backwash filters used in this application.

A benefit of the filter system design is the scale

-

ability of the filtration unit to handle high

flow rates and solids cap

acities without complicated changes to hydralic flows. Filtration

systems are

suitable for both batch and continuous processes. Optimum sizing and high

pressure drop capacity result in quick filter turnaround.

REFERENCES

1

Mott Technical Bulletin,

FCC Slurry Oil Filtration with Mott Hypulse® LSI Filters

,

www.mottcorp.com

.

2

Hastelloy is a registered trademark of Hayes

International Inc.

3

Inconel and Monel are registered trademarks of International Nickel Co., Inc.

4

Allen, Jackman and Powell,

Petroleum Refining Industry Waste Audit

, page 204, May 1990.

5

Akzo Nobel Technical Information Bulletin,

Advanced FCC Fines

Analysis

,

www.akzonobel

-

catalysts.com

.

6

Mott Technical Bulletin,

Porous Metal as a Filter Medium.

7

U.S. Patent #4,552,669, R.S. Sekellick, assigned to Mott Metallurgical Corp., November 1985.

8

Mott Technical Handbook,

Porous Metal Technology in Liquid/

Solids Separation,

Section 9.

9

Mott Technical Bulletin,

Recent Advancements in FCC Slurry Oil Filtration with Mott HyPulse LSI Filters.