Standard Specications For

Public Works Construction

2021

Edition

THE “WHITEBOOK” |

|

THE

“WHITEBOOK”

ARCHITECTURAL ENGINEERING & PARKS DIVISION

STANDARDS & CONTRACT DOCUMENTS SECTION

525 B STREET STE. 750

SAN DIEGO, CA 92101

DOCUMENT NUMBER: ECPI010122-02

Standard Specications

For Public Works Construction

2021 Edition

INTRODUCTION

Use the “WHITEBOOK” (also known as the City Supplement) in conjunction with the Standard

Specifications for Public Works Construction (“The GREENBOOK”), 2021 Edition

(http://www.greenbookspecs.org/

).

To address the special conditions of alternative contracting methods, Part 1 - GENERAL PROVISIONS

and Part 4 – EXISTING IMPROVEMENTS, have been divided as follows:

1. GENERAL PROVISIONS (A). These provisions apply to all contracts.

2. GENERAL PROVISIONS (B). When applicable, these additional provisions to GENERAL

PROVISIONS (A) apply to the alternative project contracting methods “Design-Build” (DB) and

“Multiple Award Construction Contract” (MACC).

3. GENERAL PROVISIONS (C). When applicable, these additional provisions to GENERAL

PROVISIONS (A) apply to the alternative project contracting method “Job Order Contracting”

(JOC).

4. EXISTING IMPROVEMENTS (A). These provisions apply to all contracts.

5. EXISTING IMPROVEMENTS (B). When applicable, these additional provisions to EXISTING

IMPROVEMENTS (A) apply to the alternative project contracting methods “Design-Build” (DB)

and “Multiple Award Construction Contract” (MACC) only.

STYLE OF SPECIFICATIONS

The City has standardized the style and language of The “WHITEBOOK”. This style follows the Federal

guidelines for “Plain Language” (http://www.plainlanguage.gov/

) to the extent possible. Therefore,

when used in the Contract Documents, statement or command phrases (active voice and imperative

mood) refer to and are directed at the “Bidder” or “Contractor” as applicable. The specifications are

written to the “Bidder” before award and the “Contractor” after award.

Before award, interpret sentences written in the imperative mood as starting with “The Bidder shall”.

Interpret the term “you” as “the Bidder” and interpret the term “your” as “the Bidder’s”.

After award, interpret sentences written in the imperative mood starting with “The Contractor shall”.

Interpret the term “you” as “the Contractor” and interpret the term “your” as “the Contractor’s.

DOCUMENT AVAILABILITY AND COMMENTS

An electronic copy of The “WHITEBOOK” is available for download from the City’s web site:

http://www.sandiego.gov/publicworks/edocref/greenbook.shtml

The City of San Diego is committed to the quality of this publication and desires to correct any errors,

omissions, or ambiguities. If you have any suggestions, comments, corrections, or additions, you may

submit them to: engineering@sandiego.gov

.

ACKNOWLEDGEMENT

The continuous contribution and support in standardizing and updating these specifications of the

following members and subject matter experts of the 2021 “WHITEBOOK” Committee are

acknowledged:

CITY ATTORNEY

Christina Rae, Adam Wander

RISK MANAGEMENT

Claudia Castillo DelMuro, Carla Stephens

PUBLIC UTILITIES

Tung Phung, John Miller, Andrea Demich, Anh Nguyen

ENGINEERING & CAPITAL PROJECTS

Ahmed Aburahmah, Alaine James, Angelita Jaro, Catherine Dungca, Ramesis Bustamante, Maryam

Jirjis Nakasha, Christopher Naval, Dwayne Abbey, Fletcher Callanta ,John Butcher, Harry Nguyen,

Nibras Romaya, Nabil Batta, Nikki Lewis, Randy Encinas, Sarah Chavez, Dino Ciafre-Garay, James

Arnhart, Nicole Salem, Yoftahe Ghiliamichael, Yousef Benyamin, Jacob Randles, Jayna Straughn, Maad

Al Kushaba, Darren Genova, Shannon Scoggins

PURCHASING & CONTRACTING

Claudia Abarca, Cindy Crocker, Stephen Samara

TRANSPORTATION

Duncan Hughes, Brian Genovese, Steve Celniker,

Joshua Lahmann, Edgar Puente, Gary Pence, Alexander Lukes, Mariana Sadek

STORM WATER

Michael Phillips, Chris Gascon, Jake Valencia, Jillian Haynes

PARKS & RECREATION

Charles Daniels

MOBILITY

Alex Warner

TABLE OF CONTENTS

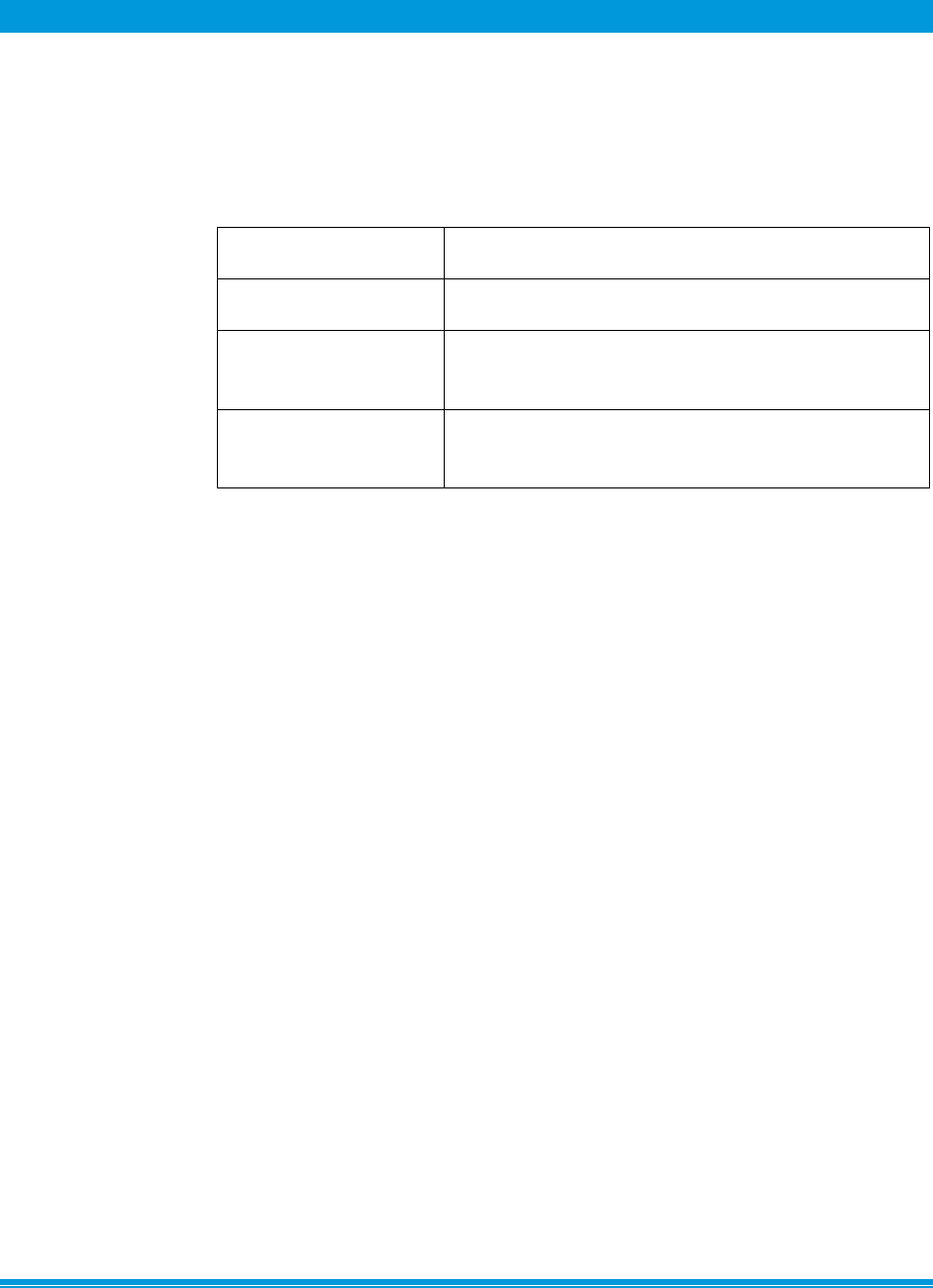

PART 1 – GENERAL PROVISIONS

GENERAL PROVISIONS (A)

SECTION 1 - GENERAL, TERMS, DEFINITIONS, ABBREVIATIONS, UNITS OF MEASURE, AND

SYMBOLS .............................................................................................................................. 11

SECTION 2 - SCOPE OF THE WORK .......................................................................................... 26

SECTION 3 - CONTROL OF THE WORK .................................................................................... 34

SECTION 4 - CONTROL OF MATERIALS ................................................................................... 76

SECTION 5 - LEGAL RELATIONS AND RESPONSIBILITIES ...................................................... 82

SECTION 6 - PROSECUTION AND PROGRESS OF THE WORK ................................................. 122

SECTION 7 - MEASUREMENT AND PAYMENT ......................................................................... 141

SECTION 8 - FACILITIES FOR AGENCY PERSONNEL ............................................................... 154

GENERAL PROVISIONS (B) - DESIGN-BUILD (DB) AND MULTIPLE AWARD

CONSTRUCTION CONTRACT (MACC) CONTRACTING ONLY

SECTION 1 - GENERAL, TERMS, DEFINITIONS, ABBREVIATIONS, UNITS OF MEASURE, AND

SYMBOLS ............................................................................................................ 158

SECTION 2 - SCOPE OF THE WORK ........................................................................................ 161

SECTION 3 - CONTROL OF THE WORK .................................................................................. 165

SECTION 4 - CONTROL OF MATERIALS ................................................................................. 170

SECTION 5 - LEGAL RELATIONS AND RESPONSIBILITIES .................................................... 171

SECTION 6 - PROSECUTION AND PROGRESS OF THE WORK ............................................... 174

SECTION 7 - MEASUREMENT AND PAYMENT ....................................................................... 175

GENERAL PROVISIONS (C) - JOB ORDER CONTRACTING (JOC) ONLY

SECTION 1 - GENERAL, TERMS, DEFINITIONS, ABBREVIATIONS, UNITS OF MEASURE, AND

SYMBOLS ............................................................................................................ 178

SECTION 2 - SCOPE OF THE WORK ........................................................................................ 183

SECTION 3 - CONTROL OF THE WORK .................................................................................. 184

SECTION 6 - PROSECUTION AND PROGRESS OF THE WORK ............................................... 185

SECTION 7 - MEASUREMENT AND PAYMENT ....................................................................... 186

PART 2 – CONSTRUCTION MATERIALS

SECTION 200 - ROCK MATERIALS .......................................................................................... 188

SECTION 201 - CONCRETE, MORTAR, AND RELATED MATERIALS ...................................... 194

SECTION 203 - BITUMINOUS MATERIALS ............................................................................. 197

SECTION 206 - MISCELLANEOUS METAL ITEMS ................................................................... 207

SECTION 207 - GRAVITY PIPE ................................................................................................ 208

SECTION 209 - PRESSURE PIPE .............................................................................................. 219

SECTION 210 - PAINT AND PROTECTIVE COATINGS ............................................................ 231

SECTION 211 - MATERIAL TESTS ........................................................................................... 232

SECTION 212 - WATER AND SEWER SYSTEM VALVES AND APPURTENANCES .......................... 233

SECTION 213 - ENGINEERING GEOSYNTHETICS ................................................................... 239

SECTION 217 – BEDDING AND BACKFILL MATERIALS ......................................................... 241

SECTION 218 - DETECTABLE WARNING TILES (DWT) ........................................................... 242

PART 3 – CONSTRUCTION METHODS

SECTION 300 - EARTHWORK .................................................................................................. 244

SECTION 301 - SUBGRADE PREPARATION, TREATED MATERIALS, AND PLACEMENT OF

BASE MATERIALS .......................................................................................... 247

SECTION 302 - ROADWAY SURFACING ................................................................................. 253

SECTION 303 - CONCRETE AND MASONRY CONSTRUCTION .............................................. 268

SECTION 304 - METAL FABRICATION AND CONSTRUCTION .............................................. 275

SECTION 306 - OPEN TRENCH CONDUIT CONSTRUCTION ................................................. 276

SECTION 307 - JACKING AND TUNNELING ........................................................................... 313

SECTION 308 - MICROTUNNELING ....................................................................................... 314

SECTION 309 - MONUMENTS ................................................................................................ 315

SECTION 314 - TRAFFIC STRIPING, CURB AND PAVEMENT MARKINGS, AND PAVEMENT

MARKERS ....................................................................................................... 316

SECTION 315 - HORIZONTAL DIRECTIONAL DRILLING ....................................................... 317

SECTION 316 - PIPE BURSTING.............................................................................................. 324

SECTION 317 - PIPE FUSION .................................................................................................. 327

PART 4 – EXISTING IMPROVEMENTS

EXISTING IMPROVEMENTS (A) – GENERAL

SECTION 400 - PROTECTION AND RESTORATION ............................................................... 336

SECTION 401 - REMOVAL ....................................................................................................... 343

SECTION 402 - UTILITIES........................................................................................................ 346

SECTION 403 – MANHOLE, SURVEY MONUMENT, AND GATE VALVE FRAMES AND COVERS

ADJUSTMENT AND RECONSTRUCTION ....................................................... 350

SECTION 404 - COLD MILLING .............................................................................................. 353

EXISTING IMPROVEMENTS (B) - DESIGN-BUILD (DB) AND MULTIPLE AWARD

CONSTRUCTION CONTRACT (MACC) CONTRACTING ONLY

SECTION 402 - UTILITIES........................................................................................................ 359

PART 5 – PIPELINE SYSTEM REHABILITATION

SECTION 500 - PIPELINE REHABILITATION .......................................................................... 361

SECTION 501 - SERVICE LATERAL CONNECTION SEALING .................................................. 374

SECTION 502 - MANHOLE AND STRUCTURE REHABILITATION .......................................... 378

SECTION 503 - SERVICE LATERAL REHABILITATION ............................................................ 381

PART 6 – TEMPORARY TRAFFIC CONTROL

SECTION 600 - ACCESS ........................................................................................................... 386

SECTION 601 - TEMPORARY TRAFFIC CONTROL FOR CONSTRUCTION AND MAINTENANCE

WORK ZONES ................................................................................................ 391

PART 7 – STREET LIGHTING AND TRAFFIC SIGNAL SYSTEMS

SECTION 700 - MATERIALS .................................................................................................... 408

SECTION 701 - CONSTRUCTION ............................................................................................ 459

PART 8 – LANDSCAPING AND IRRIGATION

SECTION 800 - MATERIALS .................................................................................................... 464

SECTION 801 - INSTALLATION .............................................................................................. 490

SECTION 802 - NATIVE HABITAT PROTECTION, INSTALLATION, MAINTENANCE, AND

MONITORING ................................................................................................ 510

PART 9 – WATER WORKS

SECTION 900 - MATERIALS .................................................................................................... 524

SECTION 901 - INSTALLATION AND CONNECTION ............................................................. 531

PART 10 – STORM WATER

SECTION 1000 - GENERAL ...................................................................................................... 547

SECTION 1001 - CONSTRUCTION BEST MANAGEMENT PRACTICES (BMPs) ....................... 549

SECTION 1002 - PERMANENT BEST MANAGEMENT PRACTICES (BMPs) ............................ 576

INDEX ............................................................................................................................... 599

City Supplement (Rev. 2021) Page 11

THE “WHITEBOOK”

PART 1

GENERAL PROVISIONS (A)

SECTION 1 - GENERAL, TERMS, DEFINITIONS, ABBREVIATIONS, UNITS OF MEASURE,

AND SYMBOLS

1-1 GENERAL. ADD the following:

1. The word “provide” shall mean “furnish and install”, unless otherwise stated.

1-2 TERMS AND DEFINITIONS. DELETE in its entirety and SUBSTITUTE with the following:

1. Acceptance – When all of the Contract Work, including all Punchlist items, is

deemed officially complete by the City Asset Owning Department or Deputy

City Engineer.

2. Addendum - Written or graphic instrument issued prior to the opening of Bids

which clarifies, corrects, or changes the Contract Documents. The term

"Addendum" shall include bulletins and all other types of written notices

issued to potential bidders prior to opening of the Bids.

3. Agency - The City of San Diego.

4. Agreed Price - The cost for new or unforeseen Work, or for adjustments in the

Contract Unit Price for changes in the character of the Work as specified in 7-

3.7, “Agreed Prices”, established by mutual agreement between you and the

City.

5. Agreement - See Contract.

6. Allowance (AL) - Payment under Allowance Bid items, denoted as “AL”, shall

be based on the actual expenditures and for pre-authorized items of the Work in

accordance with the Contract Documents. The unused portions of the Allowances

shall revert to the City upon Acceptance of the Project.

7. Apparent Low Bidder - The Bidder whose Bid having been publicly opened,

initially meets the material requirements of the Bid Documents and whose Bid

price is the lowest received.

8. Applicable Laws - Laws, statutes, ordinances, rules, orders, and regulations of

governmental authorities and courts having jurisdiction over the Project.

9. As-Builts - The CADD drawings prepared from the approved Red-lines for

record keeping purposes.

10. Award of Contract (Award) - The date on which the Mayor or designee

executes the Contract.

11. Assessment Act Contract - A Contract financed by special assessments

authorized under a State Act or procedural ordinance of a City or County.

12. Base - A layer of specified material of planned thickness placed immediately

below the pavement or surfacing.

City Supplement (Rev. 2021) Page 12

THE “WHITEBOOK”

13. Bid - The offer or proposal of the Bidder submitted on the prescribed form

setting forth the prices for the Work.

14. Bidder - Any individual, firm, partnership, corporation, or combination

thereof, submitting a Bid for the Work, acting directly or through a duly

authorized representative.

15. Board - The officer or body constituting the awarding authority of the City.

16. Bond - Bid, performance, payment bond, or other instrument of security.

17. Business Day - See Working Day.

18. Calendar Day - See Days.

19. Caltrans - The State of California Department of Transportation.

20. Cash Contract - A Contract financed by means other than special assessments.

21. Certificate of Compliance - A written document signed and submitted by a

supplier or manufacturer that certifies that the material or assembled material

supplied to the Work site conforms to manufacturer’s installation

requirements and the requirements of the Contract Documents.

22. Change Order - An amendment to the agreement signed by the City

authorizing an addition, deletion, or revision in the Work or an adjustment in

the Contract Price or the Contract time issued after the effective date of the

Contract. A Change Order may or may not also be signed by you.

23. City - The City of San Diego. See also Agency.

24. City Forces - The City’s employees who perform construction work.

25. City Supplement - the City of San Diego Standard Specifications for Public

Works Construction, the “WHITEBOOK”.

26. Code - Refer to the statutes of the State of California.

27. Contract - The written agreement between the City and you that covers the

Work.

28. Contract Documents - Contract Documents include the following: The signed

Agreement, Addenda, Notice Inviting Bids, funding agency provisions, Bid and

documentation accompanying the Bid and any post-bid documentation

submitted prior to the Notice of Award when attached as an exhibit to the

Contract, Bonds, Permits, CEQA documents, Supplementary Special Provisions

(SSP), City’s EOCP Requirements, Standard Specifications (the “GREENBOOK”), City

Supplement (the “WHITEBOOK”), Plans, Standard Drawings, Construction

Documents, Reference Specifications listed in the Notice Inviting Bids, and

Change Orders. Contract Documents, when applicable, shall also include: Site

and Coastal development permits, NEPA documents, re-vegetation plans,

biological letters or technical reports, habitat mitigation plans, storm water

documents, and local, state, and federal resource agency permits.

29. Contractor - The individual, partnership, corporation, joint venture, or other

legal entity having a Contract with the City to perform the Work. In the case of

City Supplement (Rev. 2021) Page 13

THE “WHITEBOOK”

Work being done under a permit issued by the City, the Contractor shall also

be construed as the permittee. The Contractor is referred to as “you”.

30. Contract Price - The total amount of money for which the Contract is

awarded.

31. Contract Unit Price - The amount stated in the Bid for a single unit of an item

of Work.

32. Construction Work - The portion of the Work to construct the Project as set

forth in the Contract Documents in conformance with 2-1, “WORK TO BE

DONE”.

33. Construction Documents - Your plans and details, including plans showing

installation of major systems, equipment, fixed furnishings and graphics, the

technical specifications and all other technical drawings, schedules, diagrams

and specifications, accepted Shop Drawings, Working Drawings, and

submittals that are necessary to set forth in detail the requirements for the

Project.

34. Contract Time - The number of Working Days to complete the Work as

specified in the Contract Documents. Contract Time begins at Notice to

Proceed (NTP) and ends at Acceptance.

35. County Sealer - The Sealer of Weights and Measures of the county in which

the Contract is awarded.

36. Days - Days shall mean consecutive Calendar Days unless otherwise

specified in the Special Provisions.

37. Defective Work - Work that does not conform to the Contract Documents.

38. Disputed Work - Work in which you and City are in disagreement.

39. Drawings - See Plans.

40. Electrolier - Street light assembly complete, including foundation, standard,

mast arm, luminaire, and etc.

41. Extra Work - New or unforeseen Work not covered by a Contract Unit Price or

Stipulated Unit Price.

42. Engineer - The City Engineer, Director, or other person designated, acting

either directly or through authorized agents such as the Resident Engineer.

43. Field Book - The City of San Diego Sewer Field Book or Water Gate Book

showing sewer and water facilities.

44. Field Order - A Field Order is a written agreement by the Engineer to

compensate you for Work items in accordance with 2-8, “EXTRA WORK” or 2-9,

“CHANGED CONDITIONS”. A Field Order does not change the Contract Price,

Contract Time, or the scope intent of the Contract. The unused portion of the

Field Order shall revert to the City upon Acceptance.

City Supplement (Rev. 2021) Page 14

THE “WHITEBOOK”

45. Final Environmental Document - The CEQA document issued for the Project,

such as a certified environmental impact reports, mitigated negative

declarations (MNDs), negative declarations, or exemptions.

46. Final Payment - The last payment for the Contract made to you, excluding

Retention.

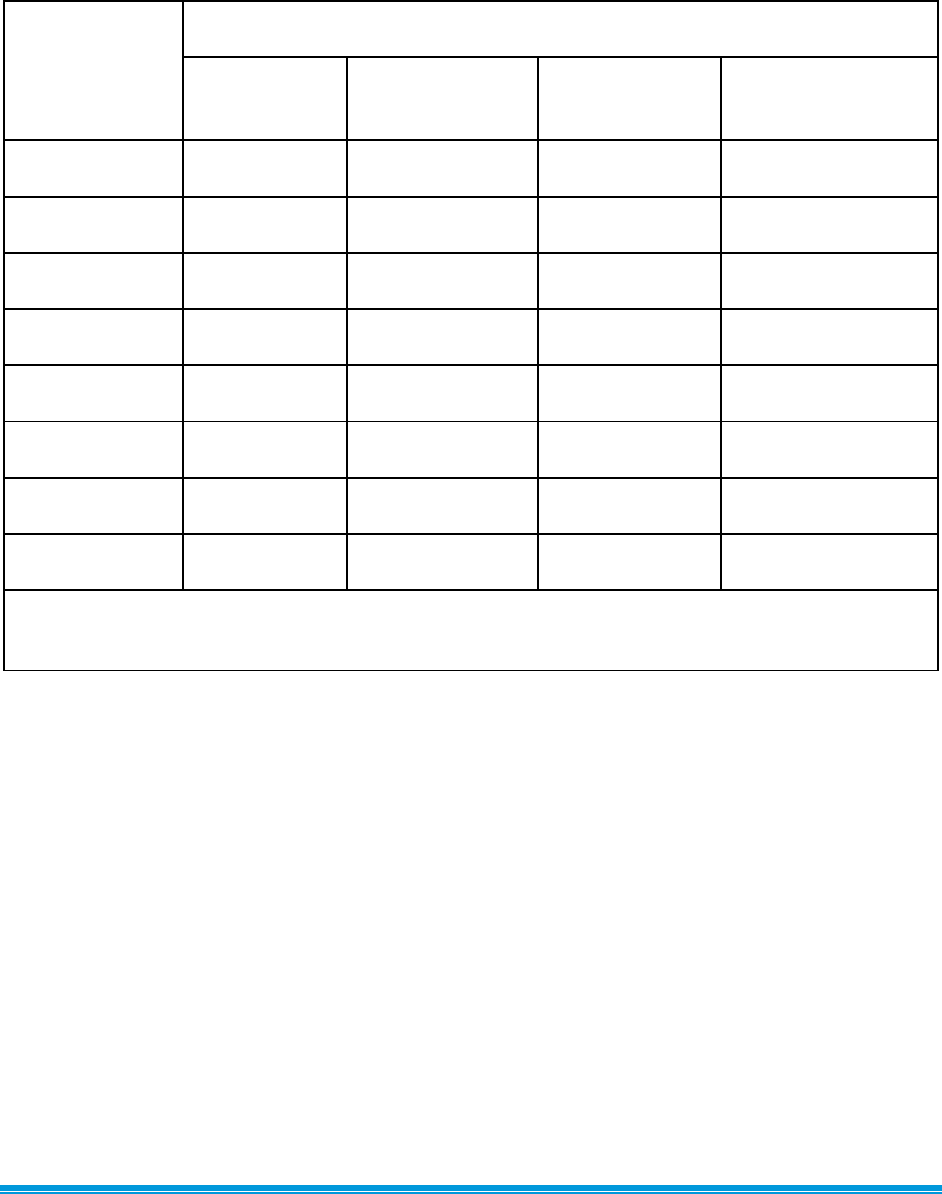

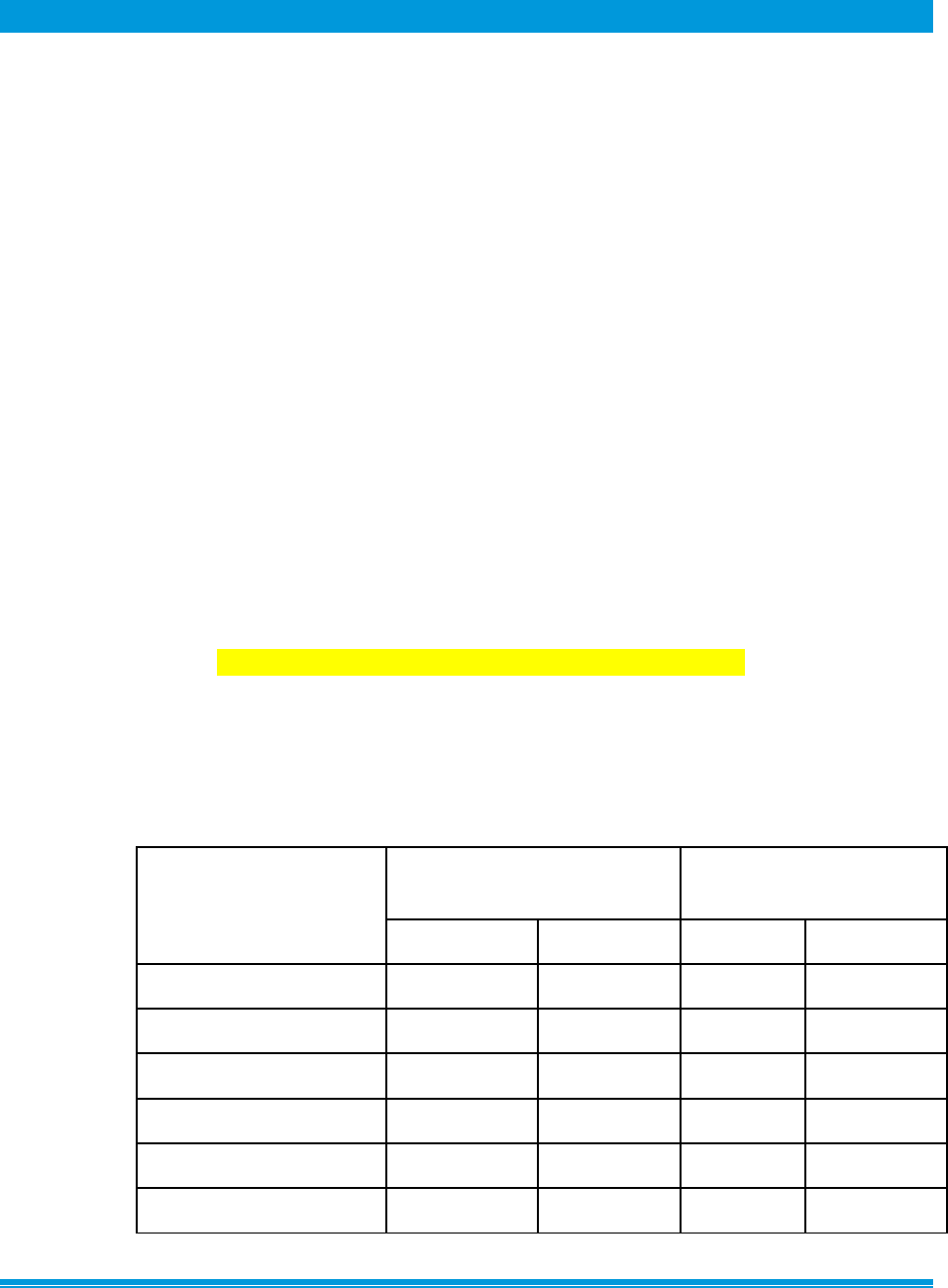

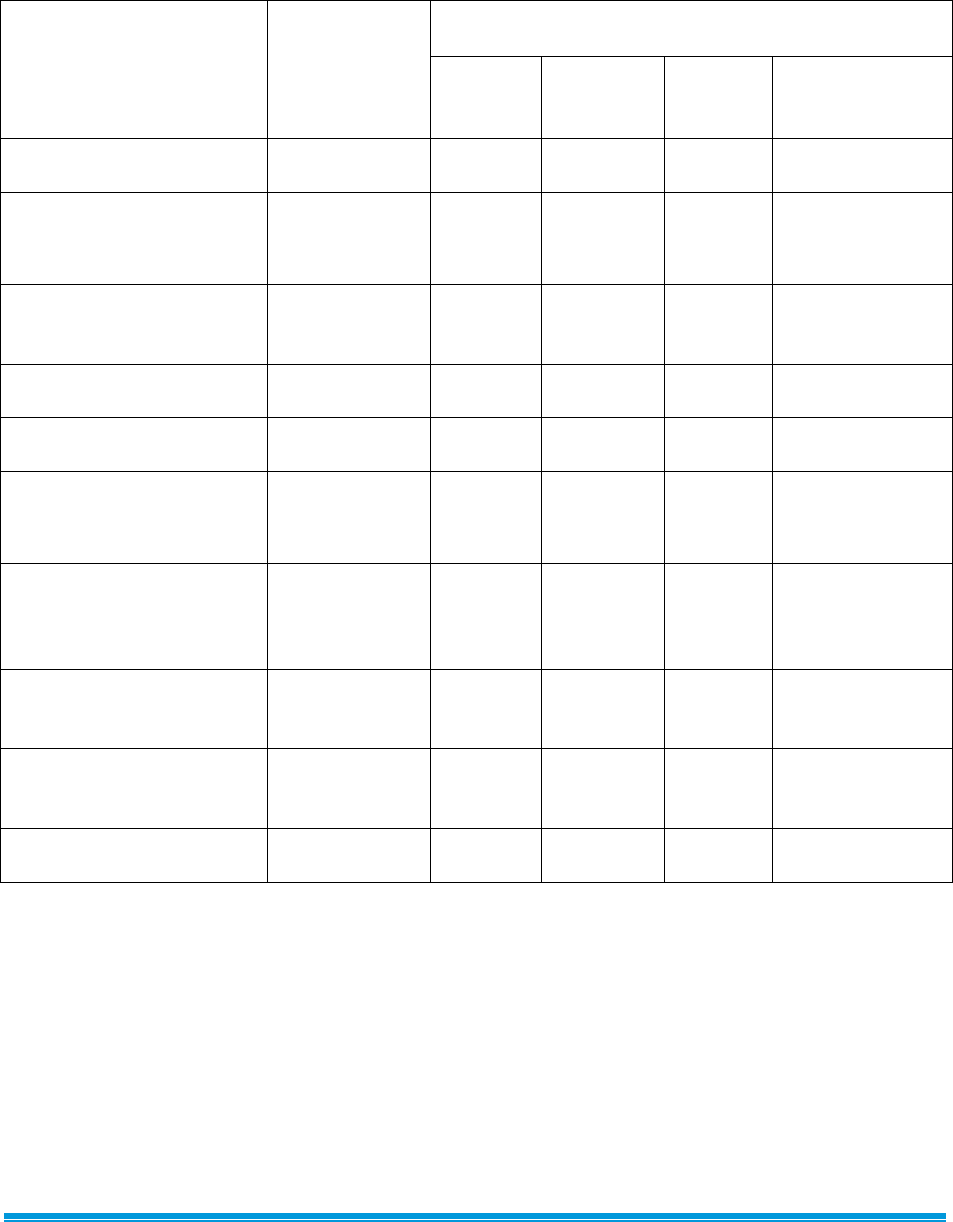

47. Holiday - Holidays observed by the City are listed below:

Holiday Observed On

New Year’s Day January 1

Martin Luther King Day 3rd Monday in January

Presidents’ Day 3rd Monday in February

Caesar Chavez Day March 31

Memorial Day Last Monday in May

Independence Day July 4

Labor Day 1st Monday in September

Veteran’s Day November 11

Thanksgiving Day 4th Thursday in November

Christmas Day December 25

If any Holiday listed falls on a Saturday, the Saturday and the preceding Friday

are both legal Holidays. If the Holiday falls on a Sunday, both Sunday and the

following Monday shall be legal Holidays. Unless specified otherwise in the

Contract Documents or authorized by the Engineer, do not work on

Holidays.

48. House Connection Sewer - A sewer, within a public street or right-of-way,

proposed to connect any parcel, lot, or part of a lot with a mainline sewer.

49. Limited Notice To Proceed (LNTP) - A written notice given from the City that

authorizes you to start a limited amount of Work that, as described in the

notice, is not Construction Work.

50. Luminaire - The lamp housing including the optical and socket assemblies

(and ballast if so specified).

51. Mast Arm - The structural member, or bracket, which, when mounted on a

Standard, supports the luminaire.

52. Mayor or Designee - The City’s Mayor or a designated representative.

City Supplement (Rev. 2021) Page 15

THE “WHITEBOOK”

53. Modification - Includes Change Orders and Supplemental Agreements. A

Modification may only be issued after the effective date of the Contract.

54. Night Work - See Working Night.

55. Normal Working Hours - Normal Working Hour core periods shall be 7:00 AM

to 5:00 PM, Monday through Friday, inclusive. Saturdays, Sundays, and City

Holidays are excluded. Unless otherwise specified, on the Traffic Control

Permits, Normal Working Hours in the are defined as 8:30 AM to 3:30 PM.

56. Notice of Award - The written notice by the City to the successful Bidder

stating that, upon its compliance with the required conditions, the City shall

execute the Contract.

57. Notice of Completion (NOC) - A document recorded with the County of San

Diego to signify that the Contract Work has been completed and accepted by

the City.

58. Notice to Proceed (NTP) - A written notice given by the City to you fixing the

date on which the Contract time shall start.

59. Occupancy – When the Owner deems a building is ready for use, the Owner

will issue a certificate of Occupancy in writing.

60. Operation, Maintenance, and Warranty Instructions - Documents published

by manufactures of pre-manufactured products describing operation,

maintenance, and any other action that shall be performed by the City as a

condition for the manufacture to honor the specified warranty.

61. Owner - See City.

62. Party or Parties - The City, you, or both, their respective permitted successors

or assigns, and any other future signatories to the Contract.

63. Person - Any individual, firm, association, partnership, corporation, trust, joint

venture, or other legal entity.

64. Plans - The Drawings, profiles, cross sections, Standard Plans, Working

Drawings, and Shop Drawings, or reproductions thereof, approved by the

Engineer, which show the location, character, dimensions, or details of the Work.

65. Prime Contractor - See Contractor.

66. Private Contract - Work subject to City inspection, control, and approval,

involving private funds, not administered by the City.

67. Private Development Projects - See Private Contract.

68. Project - The object of the Contract to be designed, constructed, or both by

you as specified, described, and shown in the Contract Documents.

69. Project Site (Site) - Areas where the Work is performed pursuant to the Contract.

70. Proposal - See Bid.

71. Punchlist - A list of items of Work or corrections generated after a Walk-through

that is conducted when you consider that the Work and Services are complete,

City Supplement (Rev. 2021) Page 16

THE “WHITEBOOK”

71. Punchlist - A list of items of Work or corrections generated after a Walk-through

that is conducted when you consider that the Work and Services are complete,

and as verified by the Owner. The Punchlist may be completed in phases if defined

in the Contract.

72. Quality Control Standards and Procedures - The standards and procedures

that are stated in a written manual that can be furnished to the Engineer upon

request. The standards and procedures are followed by the Supplier in the

production of materials supplied to the Work site.

73. Red-lines - Plans with annotations of changes made during construction to

reflect the actual product built during construction whether concealed or

visible.

74. Reference Specifications - The latest edition, including amendments, in effect

as of the date of advertisement of the Contract or issuing the permit, unless

otherwise specified, of the following:

a) Bulletins

b) Standards

c) Rules

d) Methods of analysis or testing

e) Codes

f) Installation instructions

g) Specifications of other agencies, engineering societies, manufactures,

or industrial associations referred to in the Contract Documents.

75. Retention - The amount withheld from the money due to you in accordance

with 7-3.2, “Partial and Final Payment”.

76. Roadway - The portion of a street reserved for vehicular use.

77. Samples - Physical examples which illustrate materials, equipment, or

workmanship and which establish standards that the Work shall be evaluated.

78. Schedule - A Critical Path Method (CPM) schedule prepared by you in

accordance with 6-1, “CONSTRUCTION SCHEDULE AND COMMENCEMENT OF

THE WORK” and accepted by the Engineer.

79. Scope of Work (SOW) - Labor, materials, equipment, facilities, and services

required to be performed or provided by you to complete the entire Project or

the various separately identifiable parts of the Project pursuant to the

provisions of the Contract Documents.

80. Services - Professional services such as design, engineering, and construction

management of the Project that are required in accordance with the Contract

Documents. Services are included in the Work.

81. Service Connection - All or any portion of the conduit cable or duct, including

meter, between a utility distribution line and an individual consumer.

City Supplement (Rev. 2021) Page 17

THE “WHITEBOOK”

82. Service Lateral Connection - The interface of the House Connection Sewer

with the host pipe.

83. Separate Contractors - Those individuals or entities that have entered into

arrangements with the City for the provision of labor, materials, or other services

in connection with the Project who are not under contract with you.

84. Sewer - Any conduit intended for the reception and transfer of sewage and

fluid industrial waste.

85. Shop Drawings - Drawings showing details of manufactured or assembled

products proposed to be incorporated into the Work.

86. Signal Pre-Check - The procedure that the City uses to evaluate traffic signal

systems prior to Signal Turn-On and generating a Punchlist.

87. Signal Turn-On - The day the City activates new traffic signals.

88. Special Provisions - Additions and revisions to the Standard Specifications

setting forth conditions and requirements peculiar to the Work. Examples

include the City’s EOCP Requirements, provisions for Design-Build and Job

Order Contracting Contracts, funding agency provisions, technical

specifications prepared in CSI format, the “WHITEBOOK” (City Supplement),

and Supplementary Special Provisions (SSP).

89. Specifications - Standard Specifications, Reference Specifications, Special

Provisions, and specifications in Change Orders or Supplemental Agreements

between you and the City.

90. Standard (Signal and Lighting) - The shaft or pole used to support street

lighting luminaires, traffic signal heads, mast arms, and etc.

91. Standard Plans - Details of standard structures, devices, or instructions

referred to on the Plans or in the Specifications by title or number.

92. Standard Specifications - The Standard Specifications for Public Works

Construction (SSPWC), the “GREENBOOK”.

93. State - State of California.

94. Stipulated Unit Price - Unit prices established by the City in the Contract

Documents.

95. Storm Drain - Any conduit and appurtenances intended for the reception and

transfer of storm water.

96. Street - Any road, highway, parkway, freeway, alley, walk, or way.

97. Subbase - A layer of specified material of planned thickness between the base

and the subgrade.

98. Subcontractor - An individual, firm, or corporation having a direct contract

with you or with any other Subcontractor for the performance of a part of the

Work.

City Supplement (Rev. 2021) Page 18

THE “WHITEBOOK”

99. Subgrade - For roadways, that portion on which pavement, surfacing, base,

subbase, or a layer of other material is placed. For structures, the soil prepared

to support a structure.

100. Substantial Completion – When all Contract Work is deemed complete by the

Contractor in writing, and as verified by the Owner. Substantial Completion

may be completed in phases if defined in the Contract.

101. Supervision - Supervision, where used to indicate supervision by the

Engineer, shall mean the performance of obligations, and the exercise of

rights, specifically imposed upon and granted to the City in becoming a party to

the Contract. Except as specifically stated herein, supervision by the City shall not

mean active and direct superintendence of details of the Work.

102. Supplemental Agreement – An additional agreement to the Contract

Documents signed by you and the City.

103. Surety - The company who issued the performance and payment bond.

104. Utility - Tracks, overhead or underground wires, pipelines, conduits, ducts,

structures, sewers, or storm drains owned, operated, or maintained in or

across a public right of way or private easement.

105. Walk-through - An inspection the City uses to verify the completion of the

Project or phase of the Project and to generate a Punchlist prior to Acceptance.

106. Work - That which is proposed to be constructed or done under the Contract

or permit, including the furnishing of all labor, materials, equipment, and

services.

107. Working Day - Any day other than Holidays, Saturdays, and Sundays.

108. Working Night (Night Work) - Night Work is allowed only on Sunday through

Thursday.

109. Working Drawings - Drawings showing details not shown on the Plans which

are required to be designed by you.

110. Work Site - See Project Site (Site).

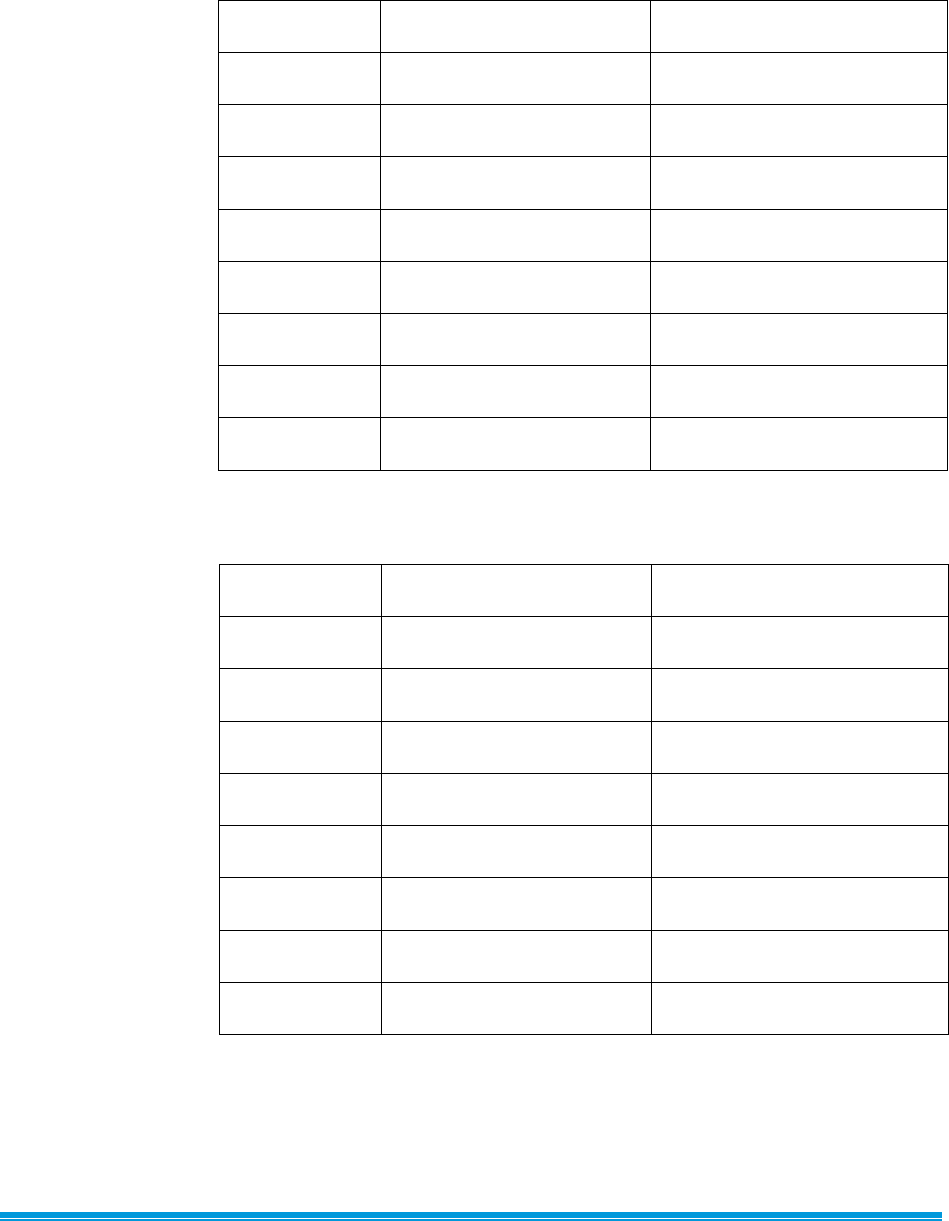

1-3.2 Common Usage. ADD the following:

1. AML ........................ Approved Material List

2. CADD ..................... Computer Aided Design and Drafting

3. CA MUTCD ............ California Manual on Uniform Traffic Control Devices

4. CCT ........................ Correlated Color Temperature

5. CEQA ..................... California Environmental Quality Act

6. CFR ......................... Code of Federal Regulations

7. CIPM ...................... Cured-In-Place-Manhole

8. CMS ....................... Content Management System Database

City Supplement (Rev. 2021) Page 19

THE “WHITEBOOK”

9. CNC ........................ Computer Numerical Control

10. CRI .......................... Color Rendering Index

11. CSA ........................ Canadian Standards Association

12. DBE ........................ Disadvantaged Business Enterprise

13. DCE ........................ Data Computer Equipment

14. DG .......................... Decomposed Granite

15. DVBE ...................... Disabled Veteran Business Enterprise

16. DWT ....................... Detectable Warning Tiles

17. EBE ......................... Emerging Business Enterprise

18. ELBE ....................... Emerging Local Business Enterprise

19. EOCP ...................... Equal Opportunity Contracting Program

20. ESL ......................... Environmentally Sensitive Lands

21. ESO ........................ Electrical Service Orders

22. FRP ......................... Fiberglass Reinforced Thermosetting Plastic

23. GFE......................... Good Faith Effort

24. GMT ....................... Greenwich Mean Time

25. GPS ........................ Global Positioning System

26. IDA ......................... International Dark Sky Association

27. IP ............................ Ingress Protection

28. LCD ........................ Liquid Crystal Display

29. LD ........................... Laser Diode

30. LER ......................... Luminaire Efficiency Rating

31. MBE ....................... Minority Business Enterprise

32. MDFT ..................... Minimum Dry Film Thickness

33. MHPA .................... Multiple Habitat Planning Area

34. MHs ....................... Manholes

35. MIL ......................... Military

36. MJ .......................... Mechanical Joint

37. M&M ...................... Maintenance and Monitoring

38. MMC ...................... Mitigation and Monitoring Coordination

39. MOV ....................... Metal Oxide Varistor

40. NA .......................... Numerical Aperture

41. NC .......................... Not connected

City Supplement (Rev. 2021) Page 20

THE “WHITEBOOK”

42. NEPA ...................... National Environmental Policy Act of 1969

43. NEXT ...................... Near End Crosstalk

44. NCHRP ................... National Cooperative Highway Research Program

45. NOC ....................... Notice of Completion

46. NTP ........................ Notice to Proceed

47. OC .......................... On Center

48. ODP ....................... Open Drip Proof

49. ONFR ..................... Optical Fiber Nonconductive Riser

50. OTDR ..................... Optical Time Domain Reflectometer

51. PB ........................... Pull Box

52. PCMS ..................... Portable Changeable Message Signs

53. PCU ........................ Photoelectric Control Unit

54. PEP ......................... Plant Establishment Period

55. PIC .......................... Polyethylene Insulated Cable

56. RFP ......................... Request for Proposal

57. RPMS ..................... Rubber Polymer Modified Slurry

58. SIC .......................... Standard Industry Classification

59. SLBE ....................... Small Local Business Enterprise

60. SMS ........................ Short Message Service

61. SMTP ..................... Simple Mail Transfer Protocol

62. SOW ....................... Statement of Work

63. SOV ........................ Schedule of Values

64. SPDT ...................... Single Pole Double Throw

65. SSD ........................ Surge Suppression Devices

66. TDR ........................ Time Domain Reflectometer

67. TEES ....................... Transportation Electrical Equipment Specifications

68. TFFN ...................... Thermoplastic Flexible Fixture Wire Nylon Jacketed

69. TIG ......................... Tungsten Inert Gas

70. UF ........................... Underground Feeder

71. UPRR ...................... Union Pacific Railroad Company

72. VAC ........................ Volts AC

73. VPC ........................ Vitrified Polymer Composite

74. WBE ....................... Women Business Enterprise

City Supplement (Rev. 2021) Page 21

THE “WHITEBOOK”

1-3.3 Institutions. ADD the following:

1. AMTRACK .............. American Track National Railroad Passenger Corp.

2. BNSF ...................... Burlington Northern Santa Fe Railway

3. DSD ........................ Development Services Department

4. IPCEA ..................... Insulated Power Cable Engineers Association

5. IES .......................... Illuminating Engineering Society (Photometric Data)

6. ISO ......................... International Organization for Standardization

7. MTS ........................ San Diego Metropolitan Transit System

8. NACE ...................... National Association of Corrosion Engineers

9. NAFP ...................... National Association of Pipe Fabricators

10. NCTD ..................... North County Transit District

11. NFPA ...................... National Fire Protection Association

12. PCI .......................... Prestressed Concrete Institute

13. PUD ........................ Public Utilities Department

14. SANDAG ................ San Diego Association of Governments

15. SD&AE ................... San Diego & Arizona Eastern Railroad

16. SDTI ....................... San Diego Trolley, Inc.

17. SDUSD ................... San Diego Unified School District

18. UPRR ...................... Union Pacific Railroad Company

1-6.2 Subcontractor Listing. ADD the following:

1. The use of Subcontractors in no way relieves you of any obligations or

responsibilities under the Contract.

2. For Subcontractor Extra Work, you shall submit Form CC10, “CONTRACT

CHANGE ORDER (CCO)” with each CCO proposal. Form CC10 is available for

download from the City’s EOCP internet site: http://www.sandiego.gov/eoc/

1-7.1 General. DELETE in its entirety and SUBSTITUTE with the following:

1-7.1 Standard Contract Provisions.

1-7.1.1 Successor's Obligations.

1. All grants, covenants, provisions and claims, rights, powers, privileges and

abilities contained in the Contract Documents shall be read and held as made

by and with, and granted to and imposed upon, you, the City, and your and the

City’s respective heirs, executors, administrators, successors, and assigns.

City Supplement (Rev. 2021) Page 22

THE “WHITEBOOK”

1-7.1.2 Waiver of Legal Rights.

1. The City’s failure to insist, in any one or more instances, upon the performance

of any provision of the Contract, or to exercise any right therein, shall not be

construed as a waiver or relinquishment of such provisions or rights.

2. Any waiver of any breach of the Contract shall not be held to be a waiver of

any other or subsequent breach.

3. Any waiver the City issues to any provision of the Contract shall only be

effective if it is agreed upon in writing by the City and if it is specific to the

particular matter concerned.

1-7.1.3 Requests for Information (RFI).

1. Should you discover a conflict, omission, errors in the Contract Documents,

differences with existing field conditions, or have any questions concerning

interpretation or clarification of Contract Documents, or when you propose

deviations to the standards or design, you shall submit a Request for

Information (RFI) to the City regarding your question or clarification within 1

Working Day.

2. Your RFI shall meet the following requirements:

a) All RFIs, whether by you or your Subcontractor or supplier at any tier,

shall be submitted by you to the City.

b) RFIs shall be numbered sequentially.

c) You shall clearly and concisely set forth the single issue for which

interpretation or clarification is sought, indicate Specification Section

numbers, Contract Drawing numbers, and details, or other items

involved, and state why a response is required from the City.

d) RFIs shall be submitted within 1 Working Day in order that they may

be adequately researched and answered before the response affects

any critical activity of the Work.

e) Should you believe that a response to an RFI causes a change to the

requirements of the Contract, you shall, before proceeding, give

written notice to the City, indicating that you believe that City response

to the RFI to be a Change Order. Failure to give such written notice

within 5 Working Days of receipt of the City’s response to the RFI shall

waive your right to seek additional time or cost.

3. The City will respond to RFIs within 5 Working Days unless the City notifies

you in writing that a response will take longer. The 5 Working Days shall begin

when the RFI is received and dated by the City. Responses from the City will

not change any requirement of the Contract unless so noted by the City in the

response to the RFI. The City will not issue a Change Order for Extra Work or

additional time when the issue raised in the RFI was due to your fault, neglect,

or any unauthorized deviations from the project design or specifications.

City Supplement (Rev. 2021) Page 23

THE “WHITEBOOK”

4. If you proceed in resolving a conflict, omission, or any error in the Contract

Documents without sending the City an RFI in accordance with the

requirements stated above, the City may require you to remove such work at

your cost or back charge You the cost to remove this work.

1-7.1.4 Assignment to Awarding Body.

1. In accordance with §7103.5(b) of the California Public Contract Code, you and

your Subcontractors shall conform to the following requirements:

a) In entering into a public works contract or a Subcontract to supply goods,

services, or materials pursuant to a public works contract, you or your

Subcontractor offer and agree to assign to the awarding body all rights,

title, and interest in and to all causes of action it may have under §4 of the

Clayton Act (15 U.S.C. Sec. 15) or under the Cartwright Act (Chapter 2

(commencing with §16700) of Part 2 of Division 7 of the Business and

Professions Code) arising from purchases of goods, services, or materials

pursuant to the public works contract or the Subcontract.

b) This assignment shall be made and become effective at the time the

awarding body tenders to you, without further acknowledgment by the

Parties.

1-7.2 Contract Bonds. DELETE in its entirety and SUBSTITUTE with the following:

1. Before execution of the Contract, file payment and performance bonds with

the City to be approved by the Board in the amounts and for the purposes

noted. Bonds shall be executed by a responsible surety as follows:

a) If the Work is being funded with state or local money, consistent with

California Code of Civil Procedure §995.670, the Surety shall be an

“admitted surety” authorized by the State of California Department of

Insurance to transact surety insurance in the State.

b) If the Work is being funded with federal money, the Surety shall be

listed in the U.S. Treasury Department Circular 570 and shall be in

conformance with the specified Underwriting Limitations.

2. Each bond shall incorporate, by reference, the Contract and shall be signed by

both the Bidder and the Surety. The signature of the authorized agent of the

Surety shall be notarized. You shall provide the following bonds:

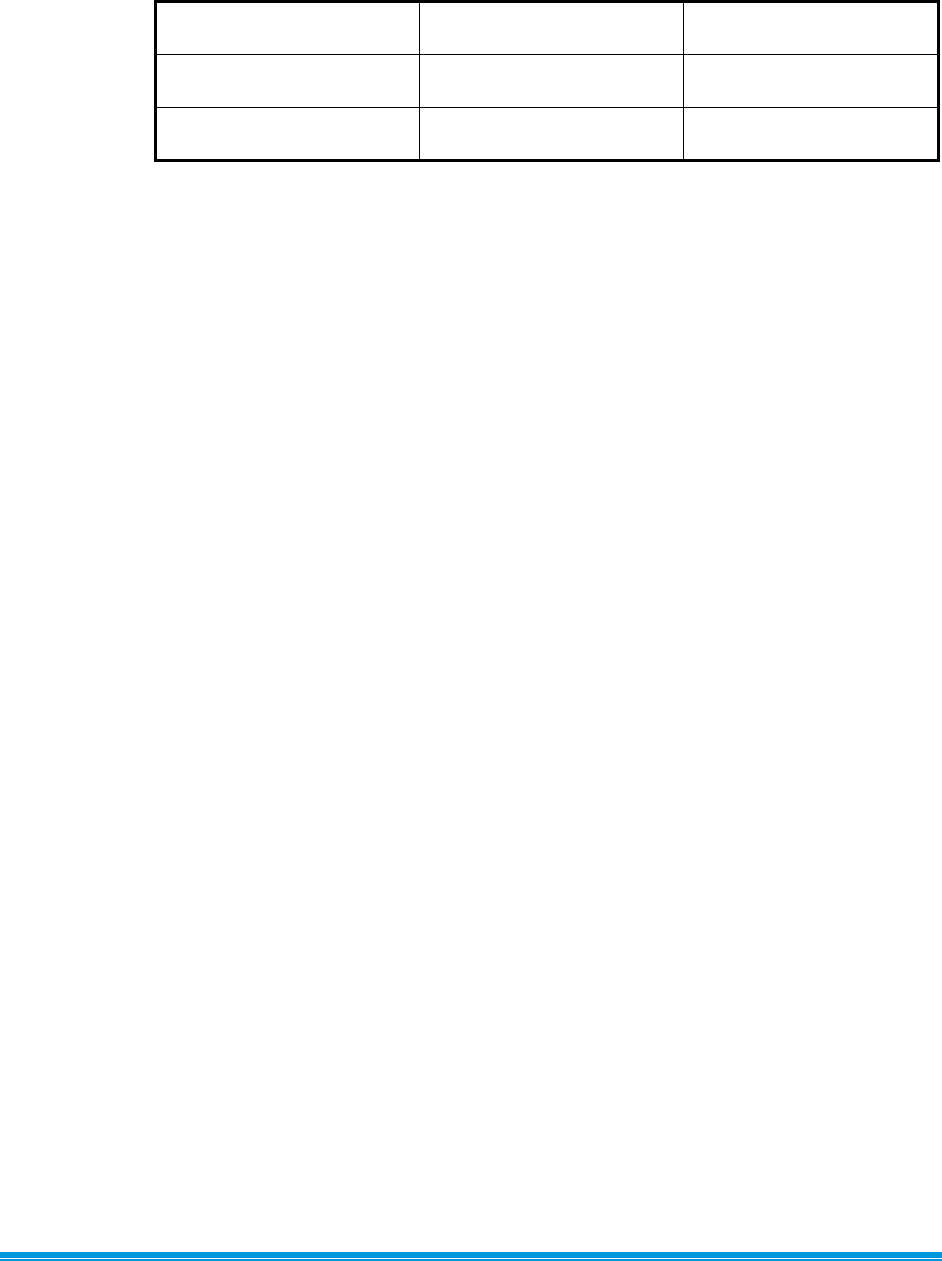

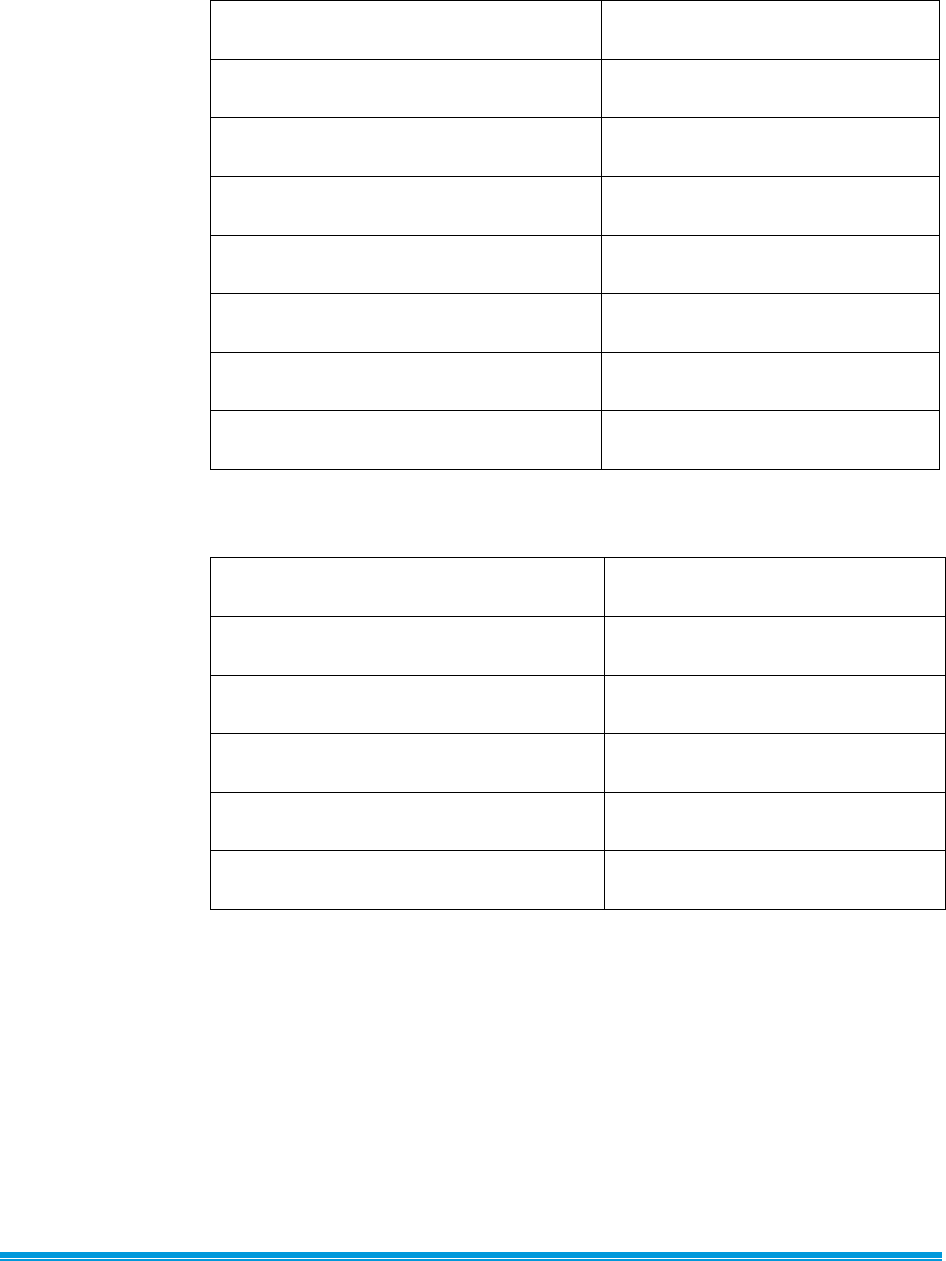

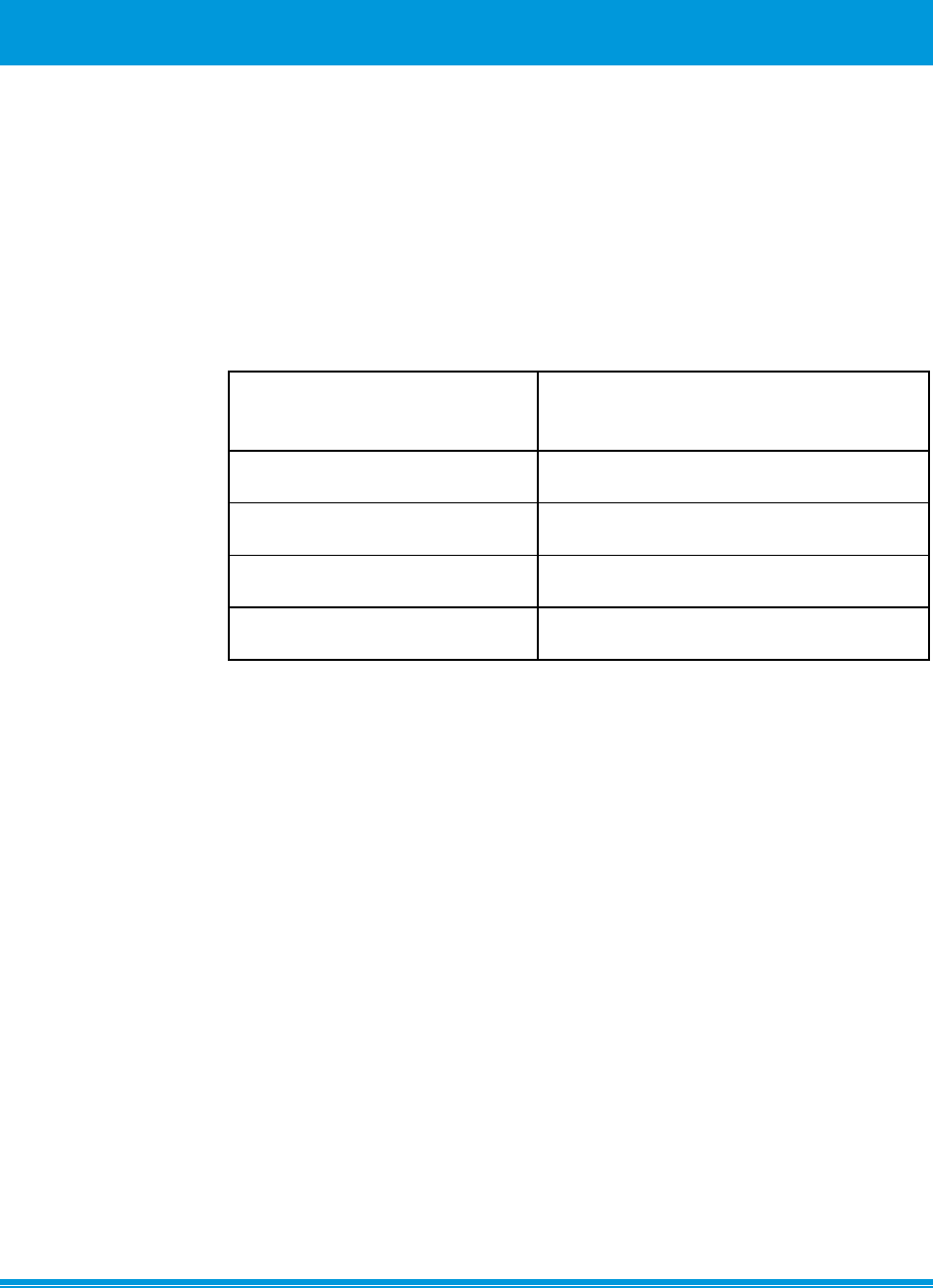

a) For Contracts less than $10,000:

i. A “Payment Bond” (Materials and Labor Bond) is optional. If

no bond is submitted, no payment shall be made until 35

Calendar Days after Acceptance and any lien requirements

have been fulfilled. If a bond is submitted, progress payments

shall be made in accordance with these Specifications.

ii. A “Faithful Performance Bond” is not required.

City Supplement (Rev. 2021) Page 24

THE “WHITEBOOK”

b) For Contracts over $10,000 and less than $25,000:

i. A “Payment Bond” (Materials and Labor Bond) is optional. If

no bond is submitted, progress payments may be made with a

minimum of 20% retention. If a bond is submitted, progress

payments shall be made in accordance with these

Specifications.

ii. A “Faithful Performance Bond” is not required.

c) For Contracts over $25,000 and less than $100,000:

i. A “Payment Bond” (Materials and Labor Bond) for not less than

100% of the Contract Price to satisfy claims of material

Suppliers and of mechanics and laborers employed on the

Work. You shall maintain the bond in full force and effect until

Acceptance and until all claims for materials and labor are paid

and shall otherwise comply with the Government Code.

ii. A “Faithful Performance Bond” is not required.

d) For Contracts over $100,000:

i. A “Payment Bond” (Materials and Labor Bond) for 100% of the

Contract Price to satisfy claims of material Suppliers and of

mechanics and laborers employed on the Work. You shall

maintain the bond in full force and effect until Acceptance and

until all claims for materials and labor are paid and shall

otherwise comply with the Government Code.

ii. A “Faithful Performance Bond” for 100% of the Contract Price to

guarantee faithful performance of Work, within the time

prescribed and in a manner satisfactory to the City, that materials

and workmanship shall be free from original or developed

defects.

e) For Contracts over $100,000 which include Community Development

Block Grant (CDBG) - HUD Program Funds:

i. A “Payment Bond” (Material and Labor Bond) for 100% of the

Contract Price to satisfy claims of material Suppliers and of

mechanics and laborers employed on the Work. You shall

maintain the bond in full force and effect until the Acceptance and

until all claims for materials and labor are paid and shall

otherwise comply with the Government Code.

ii. A “Faithful Performance Bond” for 100% of the Contract Price

to guarantee faithful performance of Work, within the time

prescribed and in a manner satisfactory to the City, that materials

and workmanship shall be free from original or developed

defects.

City Supplement (Rev. 2021) Page 25

THE “WHITEBOOK”

3. Should any bond become insufficient, renew the bond within 10 Days after

receiving notice from the City. Should any surety at any time be unsatisfactory to

the Board, notice to that effect shall be given. No further payments shall be

deemed due or shall be made under the Contract until a new surety qualifies and

is accepted.

4. Changes in the Work or extensions of time, made pursuant to the Contract, shall

in no way release you or the Surety from its obligations. Notice of such changes

or extensions shall be waived by the Surety.

5. The bond shall remain in effect until the end of warranty period set forth in

the Contract Documents.

6. If the Surety on any bond furnished by you is declared bankrupt, becomes

insolvent, or its right to do business is terminated in any state where any part

of the Project is located, immediately notify the Engineer and immediately

substitute another bond and surety acceptable to the City.

7. You shall require the Surety to mail its standard “Bond Status” form to the

Engineer at the following address:

Deputy Director

Construction Management and Field Engineering Division

9573 Chesapeake Drive San Diego, CA 92123

ADD:

1-7.2.1 Payment.

1. The Bid item for “Bonds (Payment and Performance)” includes full

compensation for actual costs of payment and performance bonds. You may

submit a request for payment of actual invoiced costs up to the bid amount,

but not to exceed 2.5% of the Contract Price, no less than 10 Working Days

after the award of the Contract.

2. If the Bid item for “Bonds (Payment and Performance)” exceeds actual invoiced

costs, any such differential amount up to the bid amount shall be paid as a

part of the Final Payment.

City Supplement (Rev. 2021) Page 26

THE “WHITEBOOK”

SECTION 2 - SCOPE OF THE WORK

2-1 WORK TO BE DONE. ADD the following:

1. Where approval or acceptance by the City is required, you shall understand it

to be a general approval only and that it does not relieve you from your

responsibility for complying with all applicable laws, codes, and best industry

practices.

2. In accordance with the provisions of California Law, you shall possess or

require your Subcontractor(s) to possess valid appropriate license(s) for the

Work being performed as conveyed in the bidding documents.

2-2 PERMITS. DELETE in its entirety and SUBSTITUTE with the following:

2-2 PERMITS, FEES, AND NOTICES.

1. You shall obtain and pay for all business taxes, permits, and fees required for

constructing the Project and licenses and inspections necessary for the proper

execution and completion of the Work, unless specified otherwise in the

Contract Documents.

a) To the extent that there is a change in the type or cost of any of such

permits, fees, licenses, or inspection occurring after Award of Contract,

there shall be an equitable adjustment in the Contract Price on

account of such change under the Extra Work provisions.

b) You shall comply with and give notices required by applicable laws.

You are not entitled to damages or additional payment for delays

attributable to the acquisition of permits.

c) You shall pay the City for regulatory fees, fines, or penalties imposed

on the City arising from your failure to complete the Work in

accordance with the Contract Documents.

2-2.1 Building Permits.

1. You shall obtain the required building permits from DSD. Any prior approval

obtained for the Plans shall not in any way waive this requirement.

2. Request inspections in accordance with the building codes in effect on the

permitted plans and by DSD. Any Work performed without the benefit of the

required permit and subsequent inspection shall be removed and replaced at

the discretion of the City Building Inspector at no additional cost.

2-2.2 Caltrans Encroachment Permit.

1. Unless specified otherwise, the City has applied for the Caltrans

Encroachment Permit.

a) You shall pay for and secure the permit prior to construction.

b) You shall arrange and pay for inspection as required by Caltrans.

City Supplement (Rev. 2021) Page 27

THE “WHITEBOOK”

2. You are solely responsible for permit processing delays to the Contract Time

that result from incomplete or inaccurate information provided by you to the

City or Caltrans.

2-2.3 Payment.

1. The payment for procuring Building Permits shall be included in the Allowance

Bid item for “Building Permits”.

2. When provided, the Allowance Bid item for “Caltrans Encroachment Permit

Submittal” shall include the payment for applying and obtaining the Caltrans

Encroachment Permit and shall include costs for preparing plans and

addressing Caltrans comments.

2-3 RIGHT-OF-WAY. ADD the following:

1. You shall be responsible for coordinating with property owners on the timing

of accessing private property when the City has already obtained rights of

entry. You shall protect any private improvements.

2-5.2 Temporary Utility Services. ADD the following:

1. You shall provide and pay for all electrical, gas, and water required for

construction and maintenance activities until Acceptance.

ADD:

2-5.2.1 Water for Construction Purposes.

1. You shall purchase all water for construction such as water used for initial

filling and final flushing of new pipeline, Site maintenance, and maintenance

of the vegetation and landscaping items of the Work.

2. You shall use the 2.5-inch (63.5 mm) fire hydrant port.

3. You shall obtain a meter and comply with the Fire Hydrant Meter Policy, Water

Department Instruction, Department Instruction #55.27, dated April 21, 2000,

that will be attached to the Contract. Violation of these requirements shall

be subject to fines or penalties pursuant to the City municipal code, §§67.15

and 67.37.

ADD:

2-5.2.2 Payment.

1. Providing and paying for all electrical, gas, and water required for construction

and maintenance activities until Acceptance shall be included in the Contract

Price.

2-6 CHANGES REQUESTED BY THE CONTRACTOR. ADD the following:

1. Any plan or method of Work suggested to you by the City, but not specified or

required by the Contract or Change Order, which is adopted or followed by

you in whole or in part shall be done at your sole risk and responsibility.

2. The Contract Price is not subject to adjustment for any type of tax increases

after the Award.

City Supplement (Rev. 2021) Page 28

THE “WHITEBOOK”

ADD:

2-6.1 Cost Reduction Proposal.

1. You may submit to the Engineer in writing, proposals for modifying the Plans,

Specifications, or other requirements of the Contract for the sole purpose of

reducing the total cost of construction.

2. The cost reduction proposal shall not impair, in any manner, the essential

functions or characteristics of the Project such as service life, economy of

operation, ease of maintenance, desired appearance, or design and safety

standards.

3. Include the following information in the cost reduction proposal:

a) A description of both the existing Contract requirements for

performing the Work and the proposed changes.

b) An itemization of the Contract requirements that shall be changed if

the proposal is adopted.

c) A detailed estimate of the cost of performing the Work under the

existing Contract and under the proposed change.

d) A statement of the time within which the Engineer shall make a

decision.

e) The Contract items of Work affected by the proposed changes,

including any quantity variation attributable thereto.

4. This subsection does not require the Engineer to consider any cost reduction

proposal. The City shall not be liable to you for not approving or acting upon

any cost reduction proposal you submitted nor for any delays to the Work

attributable to the proposal.

5. If a cost reduction proposal is similar to the information included in the

Contract Documents or adopted by the City after the advertisement for the

Contract, the Engineer will not accept such proposal and reserves the right to

make such changes without compensation to you under the provisions of this

subsection.

6. You shall continue to perform the Work in accordance with the requirements

of the Contract until a Change Order incorporating the cost reduction proposal

has been issued.

7. The Engineer is the sole judge of the acceptability of a cost reduction proposal

and the estimated net savings. In determining the estimated net savings, the

City has the right to disregard the Contract Bid prices if, in the judgment of the

Engineer, such prices do not represent a fair measure of the value of the Work

to be performed or to be deleted.

8. The City reserves the right to require you to share in the City’s costs of

investigating your cost reduction proposal. When this is required, you shall

indicate your acceptance in writing allowing the City to deduct amounts

payable to you.

City Supplement (Rev. 2021) Page 29

THE “WHITEBOOK”

9. If the Engineer accepts your cost reduction proposal in whole or in part, the

Engineer shall issue a Change Order to incorporate the changes in the Plans

and Specifications which are necessary to permit the cost reduction proposal

or such part of it as has been accepted to be put into effect. If the Engineer’s

approval is conditional, the Change Order shall include any conditions upon

which the Engineer's approval is based.

10. The Change Order also includes the estimated net savings in the cost of

performing the Work due to the accepted cost reduction proposal and

provides that the Contract cost be adjusted by crediting the City with 50% of

estimated net savings amount.

11. The Contract Time shall not be extended by the acceptance of the cost

reduction proposal and the performance of the Work unless specified

otherwise in the Change Order.

12. The amount specified as payable to you in the Change Order is full

compensation for the cost reduction proposal and the performance of the

Work.

13. The City expressly reserves the right to adopt a cost reduction proposal for

general use on contracts administered by the City when it determines that said

proposal is suitable for application to other contracts. When an accepted cost

reduction proposal is adopted for general use, only the Contractor who first

submitted such proposal shall be eligible for compensation subject to this

subsection, and in that case, only for contracts awarded prior to submission

of the accepted cost reduction proposal.

14. The cost reduction proposals identical or similar to previously submitted

proposals shall be eligible for consideration and compensation under the

provisions of this subsection if the identical or similar previously submitted

proposals were not adopted for general application to other contracts

administered by the City.

15. Subject to the provisions contained herein, the City or any other public agency

shall have the right to use all or any part of any submitted cost reduction

proposal without obligation or compensation of any kind to you.

16. You shall bear all costs to revise bonds for the Project to include the cost

reduction incentive proposal Work.

2-7.1 General. ADD the following:

1. The Engineer may substitute specific sites for asphalt overlay, slurry seal, or

concrete ramp and sidewalk replacement due to utility or construction

conflicts or urgent community needs. The Engineer will adjust the location list

provided in the Contract Documents as needed.

2-8 EXTRA WORK. ADD the following:

1. Any request by you for Extra Work shall be in writing to the Engineer and shall

include itemized estimates. You shall fully itemize your Extra Work cost

estimates such as labor and payroll costs, quantities, crew composition,

City Supplement (Rev. 2021) Page 30

THE “WHITEBOOK”

production rates, material costs, Subcontractor and Supplier costs, equipment

costs, supplemental costs, and time impact.

2. Compensation for “Time-and-Material” emergency Contracts:

a) You will be compensated for charges directly associated with the

project. staff

b) Any invoiced off site work shall include a summary of work.

c) Markup for off site work shall be the same as on site work.

ADD:

2-10.1 Claims.

1. A Claim is a written demand by you that seeks an adjustment in the Contract

Price, Contract Time, or other relief associated with a dispute arising under or

relating to the Contract, including a breach of any provision thereof. A voucher,

invoice, or other routine request for payment is not a Claim.

2. A Claim shall conform to these specifications and may be considered after the

City has previously denied a request by you for a Change Order seeking the

demanded relief.

3. You shall submit a Claim to the Engineer if a dispute occurs that arises from or

relates to the Contract. The Claim shall seek all relief to which you assert you

are entitled as a result of the event(s) giving rise to the dispute. Your failure to

process a Claim in accordance with these specifications shall constitute a

waiver of all relief associated with the dispute. Claims are subject to 6-10,

“Right to Audit”.

4. You shall continue to perform the Services and Work and shall maintain the

Schedule during any dispute proceedings. The Engineer will continue to make

payments for undisputed Services and Work.

5. The City’s Claims process specified herein shall not relieve you of your

statutory obligations to present claims prior to any action under the California

Government Code.

2-10.1.1 Initiation of Claim.

1. You shall promptly, but no later than 30 Days after the event(s) giving rise to

the Claim, deliver the Claim to the Engineer.

2. You shall not process a Claim unless the Engineer has previously denied a

request by you for a Change Order that sought the relief to be pursued in the

claim.

2-10.1.1.1 Claim Certification Submittal.

1. If your Claim seeks an increase in the Contract Price, the Contract Time, or

both, submit with the Claim an affidavit certifying the following:

City Supplement (Rev. 2021) Page 31

THE “WHITEBOOK”

a) The Claim is made in good faith and covers all costs and delays to

which you are entitled as a result of the event(s) giving rise to the

Claim.

b) The amount claimed accurately reflects the adjustments in the

Contract Price, the Contract Time, or both to which you believe you are

entitled.

c) All supporting costs and pricing data are current, accurate, and

complete to the best of your knowledge. The cost breakdown per item

of Work shall be supplied.

d) You shall ensure that the affidavit is executed by an official who has

the authority to legally bind you.

2-10.1.2 Initial Determination.

1. The Engineer will respond in writing to your Claim within 30 Days of receipt of

the Claim.

2-10.1.3 Settlement Meeting.

1. If you disagree with the Initial Determination, you shall request a Settlement

Meeting within 30 Days. Upon receipt of this request, the Engineer will

schedule the Settlement Meeting within 15 Working Days.

2-10.1.4 City’s Final Determination.

1. If a settle agreement is not reached, the City shall make a written Final

Determination within 10 Working Days after the Settlement Meeting.

2. If you disagree with the City’s Final Determination, notify the Engineer in

writing of your objection within 15 Working Days after receipt of the written

determination and file a “Request for Mediation” in accordance with 2-10.2,

“Dispute Resolution Process”.

3. Failure to give notice of objection within the 15 Working Days period shall

waive your right to pursue the Claim.

2-10.1.5 Mandatory Assistance.

1. If a third party dispute, litigation, or both arises out of or relates in any way to

the Services provided under the Contract, upon the City’s request, you shall

agree to assist in resolving the dispute or litigation. Your assistance includes,

but is not limited to the following:

a) Providing professional consultations.

b) Attending mediations, arbitrations, depositions, trials, or any event

related to the dispute resolution and litigation.

City Supplement (Rev. 2021) Page 32

THE “WHITEBOOK”

2-10.1.5.1 Compensation for Mandatory Assistance.

1. The City will reimburse you for reasonable fees and expenses incurred by you

for any required assistance rendered in accordance with 2-10.1.5, “Mandatory

Assistance” as Extra Work.

2. The Engineer will determine whether these fees and expenses were necessary

due to your conduct or failure to act.

3. If the Engineer determines that the basis of the dispute or litigation in which

these fees and expenses were incurred were the result of your conduct or your

failure to act in part or in whole, you shall reimburse the City for any payments

made for these fees and expenses.

4. Reimbursement may be through any legal means necessary, including the

City’s withholding of your payment.

ADD:

2-10.2 Dispute Resolution Process.

2-10.2.1 Mandatory Non-binding Mediation.

1. If a dispute arises out of or relates to the Contract, or the breach thereof, and

if said dispute cannot be settled through contract provisions provided for

claim settlement or negotiations, the parties agree to first endeavor to settle

the dispute in an amicable manner, using mandatory mediation under the

Construction Industry Mediation Rules of the American Arbitration Association

before having recourse in a court of law.

2. To initiate mediation, the initiating party shall serve a Request for Mediation

at the American Arbitration Association (AAA).

2-10.2.2 Mandatory Mediation Costs.

1. The expenses of witnesses for either side shall be paid by the party producing

such witnesses. All other expenses of the mediation, including required

traveling and other expenses of the mediator and the cost of any proofs or

expert advice produced at the direct request of the mediator, shall be borne

equally by the parties, unless they agree otherwise.

2-10.2.3 Selection of Mediator.

1. A single mediator, knowledgeable in construction aspects and acceptable to

both parties, shall be used to mediate the dispute.

2. If AAA is used, the initiating party shall concurrently file with AAA a “Request

for Mediation” along with the appropriate fees, a copy of requested mediators

marked in preference order, and a preference for available dates.

3. If AAA is selected to coordinate the mediation (Administrator), within 10

Working Days from the receipt of the initiating party’s Request for Mediation,

the opposing party shall file the following:

a) A copy of the list of the preferred mediators listed in preference order

after striking any mediators to which they have any objection.

City Supplement (Rev. 2021) Page 33

THE “WHITEBOOK”

b) A preference for available dates.

c) Appropriate fees.

4. If the parties cannot agree on a mediator, then each party shall select a

mediator and those mediators shall select the neutral third party to mediate

the matter.

2-10.2.4 Conduct of Mediation Sessions.

1. Mediation hearings shall be conducted in an informal manner and discovery

shall not be allowed.

2. Discussions, statements, and/or admissions shall be confidential to the

proceedings and shall not be used for any other purpose as it relates to the

party’s legal position. The parties may agree to exchange any information they

deem necessary.

3. Both parties shall have an authorized representative attend the mediation.

Each representative shall have the authority to recommend entering into a

settlement. Either party may have attorney(s), witnesses, or expert(s) present.

Either party may request a list of witnesses and notifications of whether

attorney(s) shall be present.

4. Any resulting agreements from mediation shall be documented in writing.

Mediation results and documentation, by themselves, shall be “non-binding”

and inadmissible for any purpose in any legal proceeding, unless such

admission is otherwise agreed upon in writing by both parties. Mediators shall

not be subject to any subpoena or liability and their actions shall not be subject

to discovery.

ADD:

2-10.3 Forum for Litigation.

1. It is the express intention that all legal actions and proceedings related to the

Contract or Agreement with the City or to any rights or any relationship

between the parties arising therefrom shall be solely and exclusively initiated

and maintained in courts of the State of California for the County of San Diego.

ADD:

2-10.4 Pre-judgment Interest.

1. The parties stipulate that if a judgment is entered against a party for breaching

this Contract, the pre-judgment interest shall be two percent (2%) per annum.

City Supplement (Rev. 2021) Page 34

THE “WHITEBOOK”

SECTION 3 – CONTROL OF THE WORK

3-3 SUBCONTRACTORS. ADD the following:

1. You shall incorporate these Specifications in your subcontracts for the Work

being performed by your Subcontractor.

2. You shall obtain or require that each Subcontractor obtains insurance policies

in accordance with 5-4, “INSURANCE” which shall be kept in full force and effect

for the duration of the Contract and in any attached supplemental

agreements.

3. In any dispute between you and your Subcontractors, the City shall not be made

a party to any judicial or administrative proceeding to resolve the dispute.

4. You shall ensure that your Subcontractors are appropriately licensed for the

duration of the Work that is performed under the subcontracts in accordance

with 2-1, “WORK TO BE DONE”. In the event the Subcontractor is not properly

licensed, you shall cease payment to the Subcontractor for all Work performed

when the Subcontractor was not properly licensed. You shall return to the City

any payment you made to a Subcontractor for Work performed when the

Subcontractor was not licensed.

5. Where the Contract Documents require that a particular product be installed

or applied by an applicator approved by the manufacturer, ensure the

Subcontractor or Supplier employed for such Work is approved by the

manufacturer.

6. When a Subcontractor fails to prosecute a portion of the Work in a manner

satisfactory to the City, you shall remove such Subcontractor immediately

upon written request of the City, and shall request approval of a replacement

Subcontractor to perform the Work in accordance with California Public

Contract Code (PCC), Subletting and Subcontracting, Section 4107, at no added

cost to the City.

3-4 AUTHORITY OF THE BOARD AND THE ENGINEER. DELETE in its entirety and

SUBSTITUTE with the following:

1. The City has the final authority

in all matters affecting the Work. Within the

scope of the Contract, the Resident Engineer has the authority to

enforce

compliance with the Plans and Specifications. You shall promptly comply with

instructions from the Resident Engineer.

2. The decision of the Resident Engineer is final and binding on all questions

relating to: quantities; acceptability of material, equipment, or work;

execution, progress or sequence of work; requests for information (RFI), and

interpretation of the Plans, Specifications, or other Contract Documents. This

shall be precedent to any payment under the Contract.

3. The Resident Engineer shall be the single point of contact and shall be included

in all communications.

3-5 INSPECTION. ADD the following:

City Supplement (Rev. 2021) Page 35

THE “WHITEBOOK”

1. The City may utilize consultants to assist the Engineer during construction in

observing your performance. The consultant is for the purpose of assisting the

Engineer and shall not be confused with a building inspector with the City or

with a Special Inspector.

2. Code compliance testing (including Special inspection and all Geotechnical

requirements) and inspections required by codes or ordinances is your

responsibility.

3. Your quality control testing and inspections is your responsibility. Coordinate

and schedule all inspections and tests. Give the Engineer notice of when and

where tests and inspections are to be made by others. Give at least 5 Working

Days of notice for offsite inspection. Notices are not deemed effective until the

Engineer has responded and agreed to your schedule.

4. The City shall make any inspections and tests as the City deems necessary to

ensure the Work is accomplished in accordance with the requirements of the

Contract Documents (other than inspections for Work performed in

accordance with a permit). You are responsible for the inspection of all Work

performed in accordance with a permit.

5. Provide access in accordance with Cal-OSHA Standards where necessary.

6. Remove and replace any items of Work performed without the required

permit. For required subsequent inspection, remove and replace Work at the

discretion of Engineer at no additional cost to the City. Inspection of the Work

does not relieve you of full compliance with the Contract Documents.

7. Do not cover the Work prior to inspection, testing, or approval required by the

Contract Documents, the Engineer’s prior written request, or by other

agencies. If any item of Work is covered prior to obtaining the required

approvals, when requested by the Engineer, uncover the Work for inspection,

testing, and/or approval. Upon successful completion of the inspection,

testing, or approval, cover the Work afterwards again where required. You

bear all direct and indirect costs and damages of such uncovering and re-

covering and are not entitled to an increase in the Contract Price or the

Contract Time, unless you have given the Engineer and any other affected

agencies written notice of your intention to cover the Work and the Engineer

has not acted in response to such notice.

8. When specified, make arrangements for tests, inspections, and approvals

with an independent testing laboratory or entity acceptable to the Engineer,

or with the appropriate public authority. The payment for such tests,

inspections, and approvals are included in the Contract Price.

9. Unless specified otherwise, you shall pay the cost of inspections and tests.

In the event that inspections or tests reveal non-compliance with the

requirements of the Contract Documents, you shall bear the cost of corrective

measures deemed necessary by the Engineer and the cost of the City’s

subsequent re-inspection and re-testing.

City Supplement (Rev. 2021) Page 36

THE “WHITEBOOK”

ADD:

3-5.1 Remote Control Camera Inspection.

3-5.1.1 General.

1. A time lapse video robotic camera shall be installed on all stationary project

sites and Group Jobs where open trench pipe installation is to take place. A

camera is not required for Operations and Maintenance type projects such as

slurry, overlay, and sidewalk panel replacement. The camera shall be installed

at a location where most construction activity shall be captured and remain

operational throughout the project. The selected location shall be approved

by the Engineer prior to installation.

a) The camera(s) shall be operational during all hours and days when

excavation, pipe installation, and backfill is taking place. Time lapse

video robotic cameras shall provide a clear view of backfill and

compaction operations. For Group Jobs or other linear projects, the

camera shall be mounted on a portable tower or similar device and

repositioned as Work progresses.

b) The camera shall be Heavy Duty Outdoor Vehicle Mounted RobotCam

System manufactured by EarthCam, Inc. or approved equal.

c) The camera shall be removed when installed on permanent project

locations or fixtures. Electrical services shall be deactivated and

properly concealed and mounting hardware shall be removed to the

satisfaction of the Engineer.

3-5.1.2 System Requirements.

1. The camera system shall feature:

a) An outdoor robotic infrared camera system.