Risk Management Programme (RMP) Template

for Micro Abattoirs

You can use this RMP template if you:

• Slaughter and dress farmed mammals, ostriches or emus; and

• Have a low throughput; and

• Process meat for human consumption; and

• Operate a fixed or mobile micro abattoir premises; and

• Process meat for New Zealand and/or export to countries that do not

require Official Assurances.

How to complete and register the Risk Management Programme for Micro Abattoirs Page ii

This RMP template is issued by the Ministry for Primary Industries in accordance with

section 12 (3A) of the Animal Products Act 1999 for the purpose of making the

determination that the Risk Management Programme (RMP) Template for Micro Abattoirs

is valid and appropriate for the business of this kind described in the Statement of

Application.

Pages i to xvii are not part of the RMP.

Statement of Application

The application of the Risk Management Programme (RMP) Template for Micro Abattoirs is

limited to businesses that are operating a fixed or mobile micro abattoir premises for the

slaughtering and dressing of farmed mammals, ostriches or emus.

Dated at Wellington 12

th

day of December 2023.

Aaron Tangaroa

Manager Regulatory Delivery

Ministry for Primary Industries

(acting under delegated authority of the Director-General)

Contact for further information

Ministry for Primary Industries (MPI)

Animal Products

PO Box 2526

Wellington 6140

Email: animal.products@mpi.govt.nz

How to complete and register the Risk Management Programme for Micro Abattoirs Page iii

Contents

Contents iii

What this template covers v

How to Complete the Template vi

General vi

Part 1. Required Information viii

Part 2. Supporting Systems xiii

How to Register the RMP xvi

1.1 Complete the RMP template xvi

1.2 Complete the Application forms xvi

1.3 Apply for Registration xvi

1.4 Keeping the Registered RMP up-to-date xvii

Risk Management Programme for Micro Abattoirs 1

Part 1: Required Information 1

1.1 Identifying Information 1

1.2 Day-to-day Manager 1

1.3 Operator Name, Business Address and Contact Details 2

1.4 Scope of the RMP 3

1.5 Other Activities, Risk-based Measures or Operators 5

1.6 External Verification 6

1.7 RMP Document List 7

1.8 Authorisation of the RMP 10

Part 2: Supporting Systems 11

A. Document Control and Record Keeping 11

B. Personnel Health and Hygiene 14

C. Personnel Competencies and Training 18

D. Operator Verification 20

E. Design, Construction and Maintenance of Buildings, Mobile Premises, Facilities and

Equipment 24

F. Water 29

G. Cleaning and Sanitation 36

H. Receipt of Incoming Materials and Live Animals 39

I. Traceability, Inventory and Labelling 41

J. Calibration 43

K. Chemical Control 45

L. Pest Control 47

M. Non-conforming Product and Recall 49

N. Corrective Action 52

O. Storage 54

Part 3: Regulatory Limits and Hazard Analysis 1

How to complete and register the Risk Management Programme for Micro Abattoirs Page iv

How to complete and register the Risk Management Programme for Micro Abattoirs Page v

What this template covers

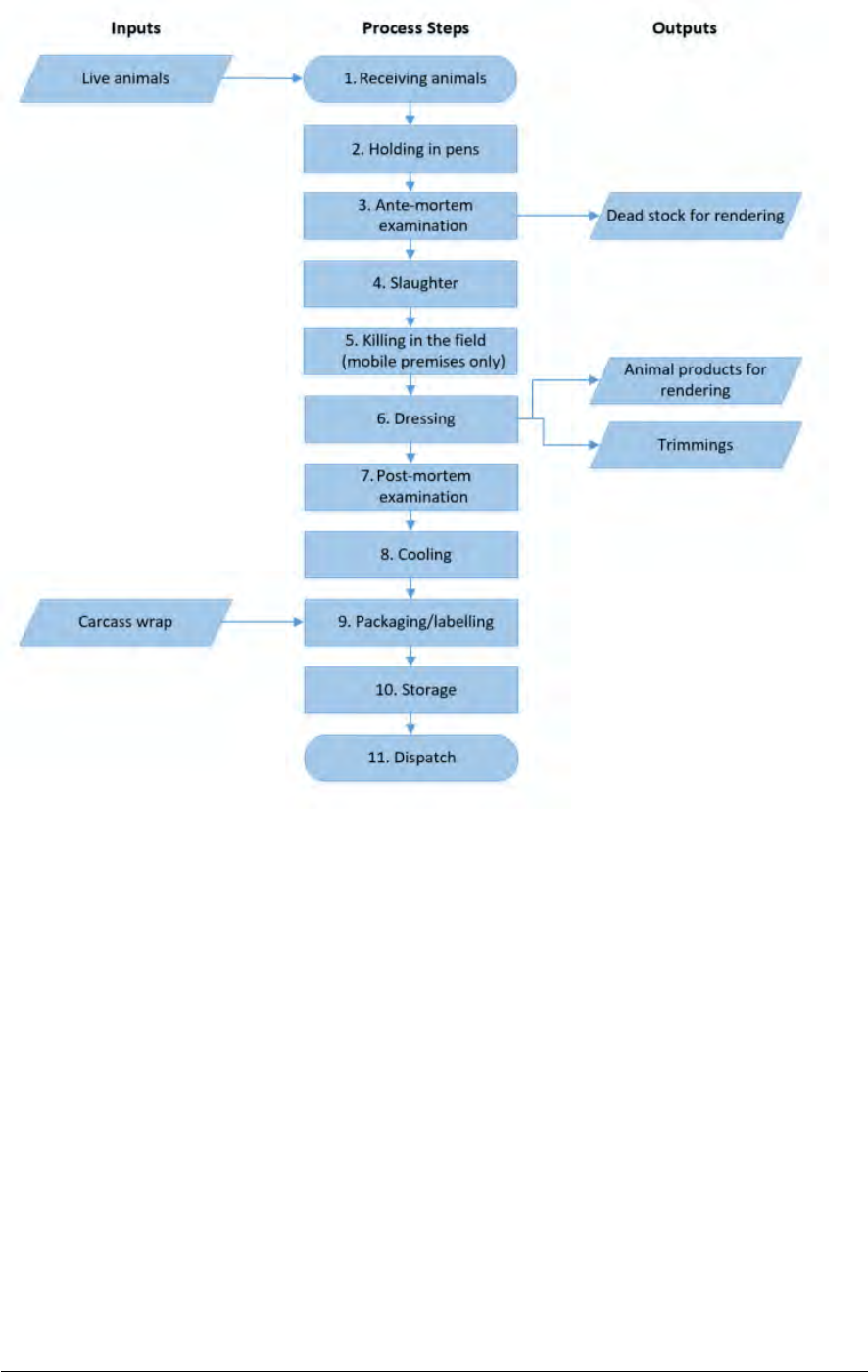

(1) This RMP template applies to the primary processing of farmed mammals, ostriches or

emus by the RMP operator.

(2) This RMP template applies to operators that are:

a) slaughtering and dressing farmed mammals, ostriches or emus; and

b) have a low throughput; and

c) process meat for human consumption; and

d) operate a fixed or mobile micro abattoir premises; and

e) process meat for New Zealand and/or export to countries that do not require

Official Assurances.

(3) A micro abattoir is not allowed to do any homekill or recreational catch activities under

section 70 of the Animal Products Act 1999.

(4) Micro abattoirs are not the same as dual operator butchers (DOB) who are able to

operate a retail butchery (secondary processing) that sells regulated animal products

and processes homekill or recreational catch (see Risk Management Programme

Template for Dual Operator Butchers).

(5) This RMP template does not apply to operators covered under a different RMP,

Regulated Control Scheme or a risk-based measure under the Food Act 2014 (e.g. Food

Control Plan or National Programme), or operators that process, transport and store:

a) other animal products; and

b) other food products; and

c) other non-food products.

(6) This RMP template has been developed based on New Zealand requirements only as

the scope of the template only covers product for New Zealand or for export to

countries where official assurances are not required.

(7) If your operations are not fully covered by this template, or you decide to deviate from

the requirements and procedures given in this template, you can do so by modifying

this template, or writing your own RMP. In most cases, these changes will need to be

evaluated by an MPI recognised RMP evaluator. If you decide to make changes to this

template after you have registered it, you will need to talk to your verifier first.

How to complete and register the Risk Management Programme for Micro Abattoirs Page vi

How to Complete the Template

General

(1) You need to provide complete and accurate information as the registered RMP is a

legally binding document that must be complied with. Everything written down needs

to accurately reflect or apply to your operation.

(2) You can complete this RMP template electronically as it is an editable PDF document,

or you can print it off and manually complete it. If you are manually completing your

RMP template, you must ensure that all information is clear and easy to read.

(3) The template should be completed by a person or group of people who have full

knowledge of the whole operation covered by the RMP.

(4) You need to read each section of this guidance while completing the template.

(5) You must provide the required information by entering information into the empty

boxes or blank lines; or ticking the appropriate answer or information.

(6) Your final RMP will be the completed RMP template (Part 1: Required Information,

Part 2: Supporting Systems and Part 3: Regulatory Limits and Hazard Analysis) and all

the additional documents you have written yourself and listed in the document list.

(7) You must comply with all the requirements and procedures in the final RMP, including

those in the supporting systems and all the additional documents you have written

yourself and listed in the document list.

(8) If you need to make changes to this template to better suit your operation, you can do

so by modifying this template or writing your own RMP. In most cases, these changes

will need to be evaluated by an MPI recognised RMP evaluator. If you decide to make

changes to this template after you have registered it, you will need to talk to your

verifier first.

(9) By complying with the requirements and procedures given in this template, you will be

meeting the requirements for the primary processing of animal products that are

specified in the current versions of:

Animal Products Act 1999

www.legislation.govt.nz/act/public/1999

/0093/latest/DLM33502.html

Animal Products

Regulations 2021

www.legislation.govt.nz/regulation/publi

c/2021/0400/latest/LMS520972.html

How to complete and register the Risk Management Programme for Micro Abattoirs Page vii

Animal Products Notice:

Production, Supply and

Processing

www.mpi.govt.nz/dmsdocument/50182

(10) You can refer to the Red Meat Code of Practice (www.mpi.govt.nz/food-

business/meat-game-processing-requirements/meat-game-codes-

practice-risk-management-programme-documents/) for additional useful

information.

(11) Where you need to develop additional procedures and forms, you can

use and adapt the examples of forms and procedures from the RMP

Operator Resource Toolkit (www.mpi.govt.nz/dmsdocument/26566).

How to complete and register the Risk Management Programme for Micro Abattoirs Page viii

Part 1. Required Information

1.1 Identifying Information

RMP ID – if you do not already have a RMP ID, you can nominate your own

identifier when you complete the AP4 Application form

(www.mpi.govt.nz/dmsdocument/71). Your identifier must be a number/letter

combination of at least 3 and no more than 10 characters, with at least one

character a number and no leading zeros.

If you have more than one RMP, assign a consecutive two digit number (01-99) to each new

RMP you have. Enter 01 if this is your first RMP.

For example: 100% ABC NZ Ltd could nominate an identifier of 100ABC/01 for their first

RMP.

If you don’t nominate an identifier, MPI will assign one for you. If the identifier you

nominate is not in the appropriate format, or is already in use, MPI will suggest an

alternative.

1.2 Day-to-day Manager

Day-to-day manager of the RMP – also referred to as the RMP Manager, you must nominate

a day-to-day manager who will be responsible for implementing the RMP and ensuring that

it is kept up-to-date. They will be the contact person for MPI and the verification agency

when dealing with matters relating to the RMP.

It is recommended that the position be given instead of the name of the day-to-day manager

to avoid the need for amending the template and notifying MPI when this person is

replaced. You may also wish to identify a deputy to the day-to-day manager.

Email – you must enter the email address that can be used to contact the Day-to-day

manager of the RMP.

Mobile phone number – you must enter a mobile phone number that can be used to contact

the day-to-day manager of the RMP. If there is no mobile number, a landline number may be

entered.

1.3 Operator Name, Business Address and Contact Details

NZBN – you must provide your NZBN here if you have one. If you want more

information about NZBNs, see www.nzbn.govt.nz.

Full Legal Name - if the business is a registered company, then you must use

the full legal name that matches the details given at the Companies Office exactly. If the

business is a partnership or a sole trader operation, then you must provide the name(s) of

the business owner(s)/partners.

How to complete and register the Risk Management Programme for Micro Abattoirs Page ix

Trading Name – you must fill this in if the name the business trades under (i.e. the name

used on a shop sign or letterhead) is different to the full legal name. If you don’t have a

trading name then you can leave this blank.

Physical address of premises (fixed premises) – you must give the street address of the

premises that the RMP applies to. If this RMP is for one business with multiple sites, include

the addresses for the additional sites as a separate, clearly named, attachment.

Main address of premises (mobile premises) – you must give the address of the location that

the mobile premise is parked when not in use.

Vehicle registration number (mobile premises) – you must give the vehicle registration

number of the mobile premises that the RMP applies to. If you have a mobile premise and

update your vehicle you need to update your RMP.

Postal address – if the postal address is different to the main address, you must give the

address any correspondence should be sent to, including the postcode.

Phone number – you must enter a phone number that can be used to contact the RMP

operator. Enter a phone number even if this is the same as the phone number under 1.2

Day-to-day Manager.

Mobile phone number – you must enter a mobile phone number that can be used to contact

the RMP operator. Enter a mobile phone number even if this is the same as the mobile

phone number under 1.2 Day-to-day Manager.

Email – you must enter the email address that can be used to contact the RMP operator.

Enter an email address even if this is the same as the email address under 1.2 Day-to-day

Manager.

1.4 Scope of the RMP

Physical Boundaries – you must include a site plan as part of the RMP. The site plan should

be labelled to make it clear it is part of the RMP. If this RMP covers more than one site, you

must attach a site plan for each site. Tick the box to indicate that you have a site plan and be

sure to attach it when submitting the RMP for registration.

For fixed premises, your site plan must show the buildings, facilities and

external surroundings included under your RMP. The different rooms or areas

within a building and the location of key pieces of processing and hygiene

equipment should also be shown in the diagram(s). The physical boundary of

the RMP will need to be clearly indicated on the site plan. Generally, the physical boundary

of a fixed premises is the legal boundary or the fence line of the property. Areas and facilities

within the boundary that are excluded in the RMP should also be clearly indicated on the

site plan. See the RMP Manual (www.mpi.govt.nz/dmsdocument/183) for an example.

For mobile premises, your site plan must show the layout of each vehicle, including storage

facilities, and the location of key pieces of processing and hygiene equipment on the site

plan. The physical boundaries of the RMP for a mobile premises are formed by the outer

How to complete and register the Risk Management Programme for Micro Abattoirs Page x

extremities of the mobile facility. Note: for a mobile premises, employee amenities do not

need to be located within the RMP premises.

Processing – tick the box(es) to indicate what processing your RMP covers. At the time of

registration, your operation must be capable of carrying out the processes that you indicate.

If you modify the template with additional processes these may need to be evaluated by an

MPI recognised RMP evaluator before your RMP can be registered with MPI.

1.5 Other Activities, Risk-based Measures or Operators

You must fill out this table if there are any products or activities that occur on the same

premises or within the physical boundaries of the RMP, but are not covered by this RMP

template because:

• they are covered under a different risk-based measure (e.g. an RMP, a Regulated

Control Scheme, a Food Control Plan, a National Programme or under the Wine Act

2003); or

• they are not covered under a different risk-based measure; or

• they are carried out by a different operator.

Examples of activities that you may wish to keep under the Food Act regime are: retail shop,

secondary processing activities only for the domestic market.

Under the Animal Products Act 1999, you are not allowed to use your micro abattoir

facility for any homekill or recreational catch activities.

Note: you must have procedures that make sure that these excluded activities are not a

source of contamination to any animal products processed or stored within the physical

boundaries of the RMP.

Fill out the table as appropriate, listing:

• each activity (including processing of other products) occurring within the RMP

physical boundary that is not covered by this RMP; and

• if the activity is covered under a different RMP, Regulated Control Scheme or risk-

based measure (if yes, say which one it is covered under and include the ID if there

is one); and

• how the activity is controlled, so operations are not adversely affected; and

• who is responsible for ensuring that the control measures are implemented and

effective; and

• who is responsible for resolving any issues that occur between this RMP, and the

other activity (use name or job title, include name of different operator if

applicable).

How to complete and register the Risk Management Programme for Micro Abattoirs Page xi

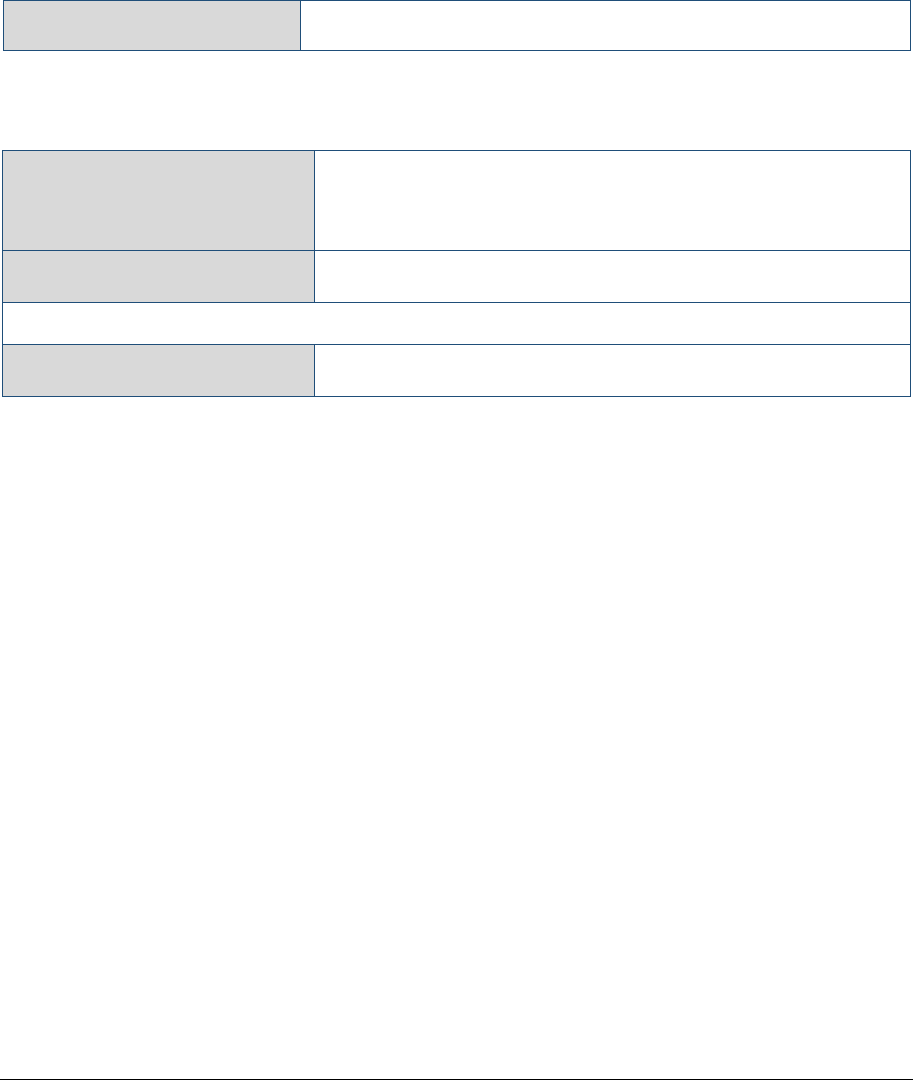

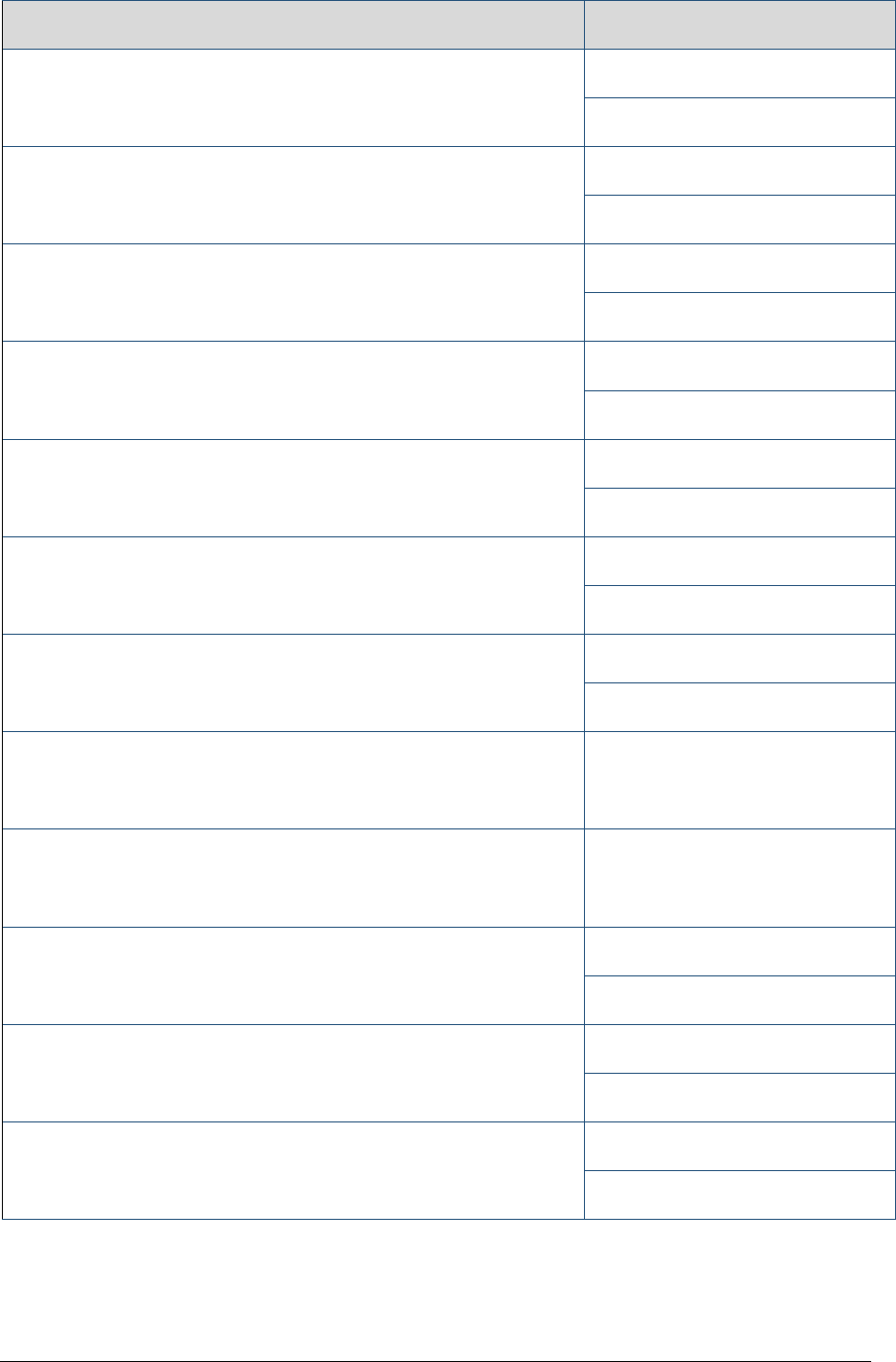

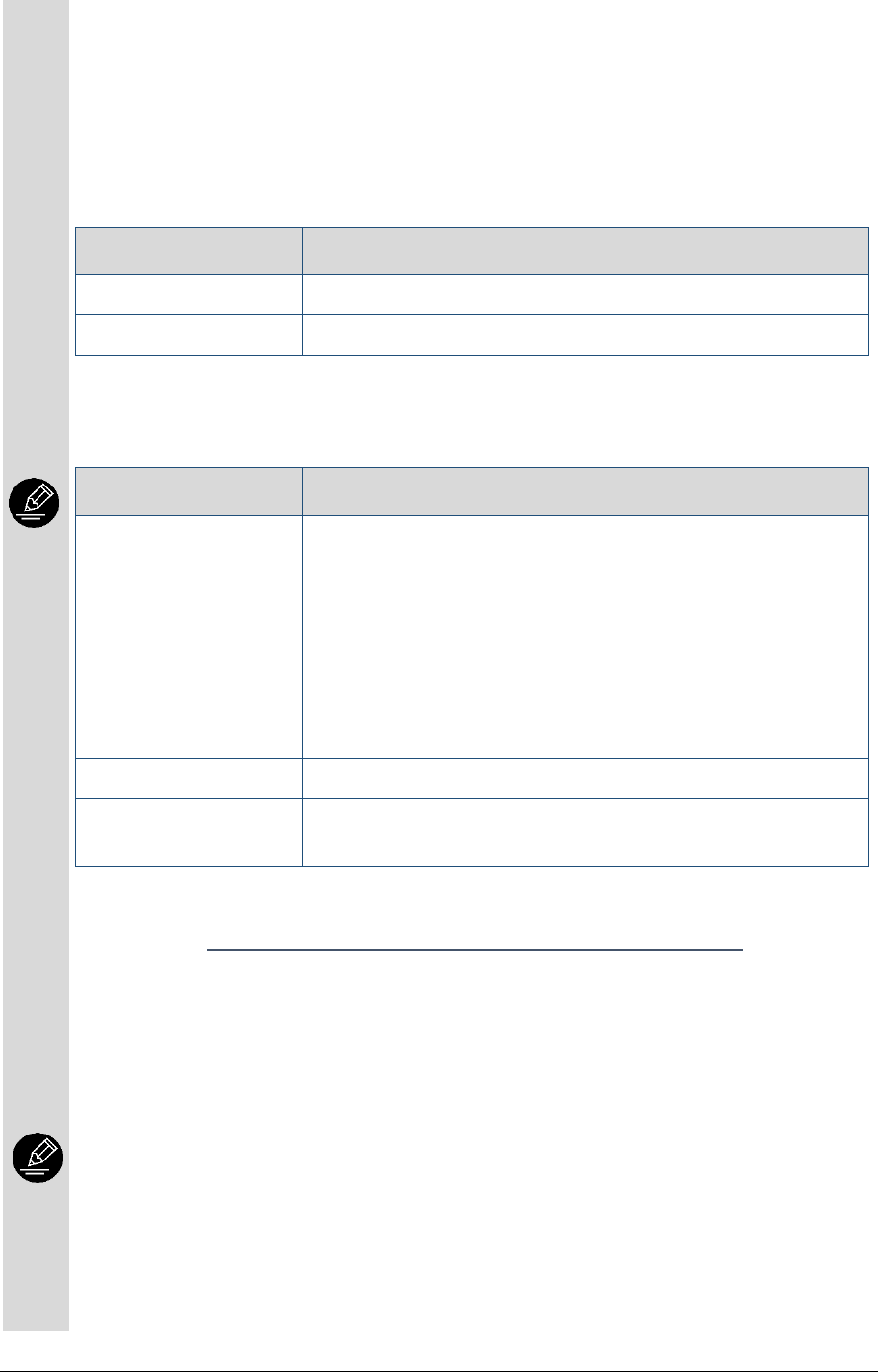

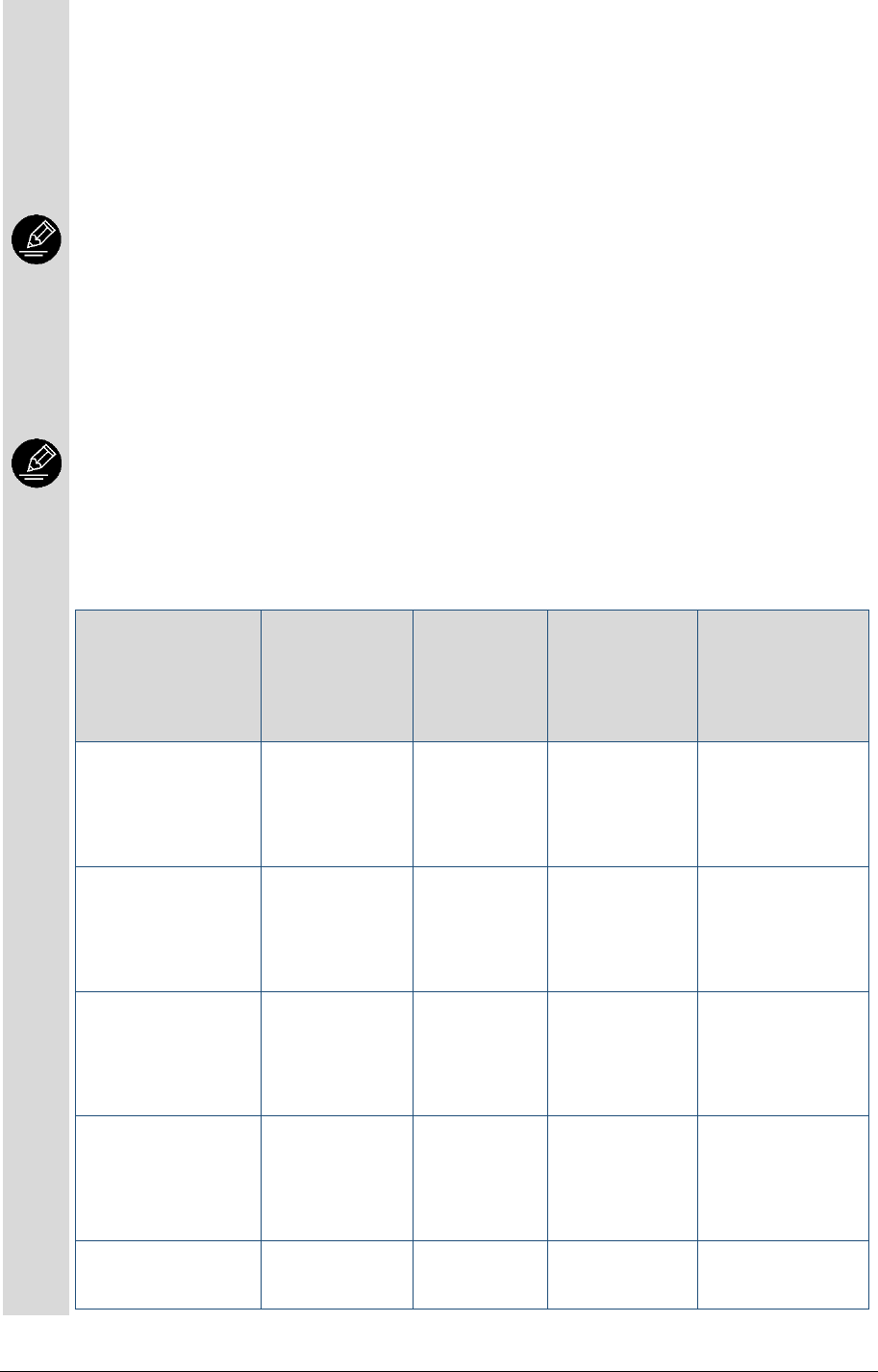

For example:

Activity Covered under a

Risk-Based Measure

(if Yes, include which

one and ID)

Control Measures

Responsibility

(Name or job title, include

name of different operator if

applicable)

Packaging of

eggs

RMP ID BUS111/01

Kept separate

from other

product and

activities

Packhouse Manager

Processing

animal feed for

sale

No

Kept separate

from other

product and

activities

Feed Mill Supervisor

Subcontract

space to store

packed paper

boxes

No

Boxes are only

allowed to be

stored in an

ambient storage

facility that is not

used by this RMP.

Storage facility has

a separate

entrance.

Lead Supervisor of the Pretty

Paper Company

If necessary, use extra pages and attach to the RMP.

1.6 External Verification

This section states that you authorise the contracted verifier to have freedom and access to

carry out verification activities. You must have a record of the name and contact details of

the verification agency and ensure that a letter has been received from the verification

agency confirming that they will verify your RMP. This letter must be provided to MPI when

applying for registration of your RMP. An electronic letter or email is fine.

The verifier must have access to any and all places, things and information that may

reasonably be needed to complete the verification (e.g. lab test results, non-conformances

and the corrective actions taken, etc.). You must tick the box to indicate that you have

contracted a verifier and have received and attached the letter from the verification agency

confirming that they will verify the RMP.

1.7 RMP Document List

Table 1: Documents from the RMP template. This gives the list of all the documents from the

RMP template that form part of your RMP. You must complete this table with the date

authorised for each document. This will be the date that the RMP is authorised (section 1.8).

How to complete and register the Risk Management Programme for Micro Abattoirs Page xii

Table 2: Procedures, programmes, water-use criteria. This table is for all the additional

documents that make up the rest of the RMP – these documents have been written by you.

You must fill in this section with the name of the document and include the name of the

person authorising the document and the date of authorisation for each of the procedures

and programmes you have written yourself or used from the RMP Operator

Resource Toolkit (www.mpi.govt.nz/dmsdocument/26566). If you have written

your own module(s), include them in this table.

Supporting systems of the RMP may require you to write procedures and

programmes covering good operating practice (GOP) and process control that are specific to

your operation and premises. Examples of the type of documents are: a cleaning

programme, cleaning schedules, calibration programme, inventory control procedures, etc.

The verifier will confirm the effectiveness of the RMP against these procedures and

programmes. You must ensure that all the written procedures and programmes apply to

your operation and that you comply with them.

These documents must be authorised by the day-to-day manager or a nominated person

and may be authorised individually and separately to the documents from the RMP template

(Table 1).

Each document must be re-authorised each time it is updated.

1.8 Authorisation of the RMP

The RMP must be authorised by either the day-to-day manager or a nominated person. Tick

the boxes to indicate which person is authorising. This person must sign, date and give their

job title.

If the person signing is a nominated person, check their name is on the list of nominated

persons referred to in the ‘Show’ section of Supporting System A. Document Control and

Record Keeping.

You must tick the boxes to confirm that you agree to the statements confirming that the

RMP is valid and appropriate for the activities it is intended to cover.

Each time you make a minor or significant amendment to the RMP, the RMP needs to be re-

authorised (signed and dated).

If you are electronically completing the RMP template and are unable to electronically sign,

then print this page, physically sign, and include a scan of the signed page when sending to

MPI.

How to complete and register the Risk Management Programme for Micro Abattoirs Page xiii

Part 2. Supporting Systems

The supporting systems in Part 2 describe the good operating practices and procedures

that you will comply with. They are part of your RMP and you will need to include them

when submitting your application.

You will need to:

a) read each supporting system thoroughly; and

b) ensure that everything in each supporting system applies to your operation and

that you will be able to comply with them; and

c) provide information suggested in some supporting systems that’s specific to your

operation by:

i) entering information into the empty boxes or blank lines; or

ii) ticking the appropriate answer or information.

d) ensure that you have written any procedures and programmes that might be

required and that these additional documents are listed in the Document List

(Section 1.7 in Part 1 of the template).

Your contracted verifier will verify the effectiveness of the RMP against the supporting

systems and the additional procedures and programmes you have written. It is a good idea

to store a copy of your procedures and programmes with your copy of the RMP.

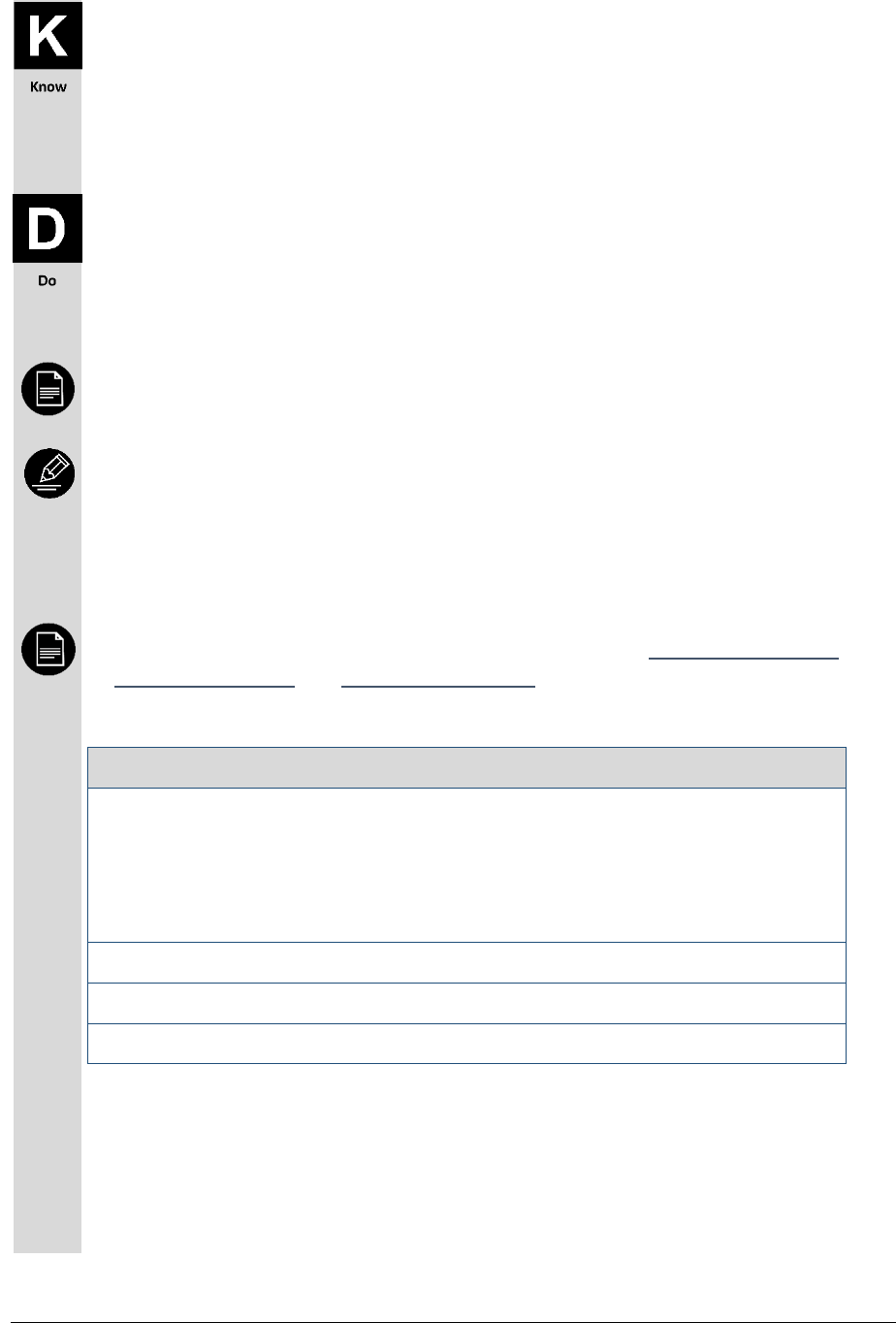

Each supporting system is written in the Know/Do/Show format.

Know has general information about why this topic is important and gives ideas

for how you can comply with food law.

Do outlines what you must do to comply with the food safety laws.

Show gives examples of records which your verifier might want to see as

evidence that you’ve done something.

The pencil icon indicates that you need to:

• enter further details or tick boxes as appropriate (e.g. monitoring frequency for

compliance with procedures, etc.) directly in the supporting system; or

• write a procedure, programme or other document that covers the points listed in

the supporting system.

How to complete and register the Risk Management Programme for Micro Abattoirs Page xiv

You can find help on writing procedures, programmes or other documents in

the Red Meat Code of Practice (www.mpi.govt.nz/food-business/meat-game-

processing-requirements/meat-game-codes-practice-risk-management-

programme-documents/).

You can find example forms and procedures in the RMP Operator Resource

Toolkit (www.mpi.govt.nz/dmsdocument/26566).

The document icon indicates that you need to keep a record of something.

Monitoring for Operator Verification

What is this?

Many of the supporting systems have a section called ‘Monitoring for Operator Verification’,

where you write in a frequency for checking that you are meeting the procedures.

Making sure that procedures are being followed is part of the ‘Operator Verification’. We

have added the ‘Monitoring for Operator Verification’ sections to help you meet these

requirements.

What timeframes should I put?

Operator Verification of procedures needs to be done at least once a year. For most

supporting systems, reviewing every 1-3 months would be appropriate. However, for an

activity that happens daily, a monthly review may be too infrequent. For an activity that

happens every month (or less often), 3 monthly might be too frequent.

Choose timeframes that are both appropriate for what you are reviewing and are

achievable.

Additional guidance for the Water supporting system

Use of water for a mobile premises

Mobile premises can use their own supply of water that meets the water-use plan (e.g.

carried in suitable containers).

Mobile premises can only use water from the property they visit if that water is also under a

water-use plan (i.e. the water is being supplied from another RMP premises who has

completed this assessment).

How to complete and register the Risk Management Programme for Micro Abattoirs Page xv

You can also write your own water-use plan to include the use of town-supply water (that is

not further treated) from any property you visit.

Town supply water

If you are using town supply water without treating it yourself, whether you need to develop

water-use criteria and perform initial water testing depends on if you have a reason to

believe the town supply water will not meet the E. coli and turbidity requirements (the

standard requirements for all water).

Generally, you can assume that town supply water will meet the standard requirements. In

this situation, the completed Water supporting system is your water use plan. You do not

need to create water-use criteria, do initial testing or routine monitoring.

If you have a reason to believe that the town supply water will NOT meet the standard

requirements, then you need to document the reason you are unsure, and you will need to

develop water-use criteria and do initial water testing. Depending on the results of the initial

testing, you may need to do routine monitoring as well.

Own-source water

If you are using own-source water, especially on mobile premises, you will need to develop

water-use criteria and do initial water testing. Depending on the results of the initial testing,

you may need to do routine monitoring as well.

You can complete the Own-source water checklist and template water-use

plan (www.mpi.govt.nz/dmsdocument/56140). When this is completed, this,

combined with the Water supporting system, will be your water use plan and

will include the water-use criteria.

The Own-source water checklist and template water-use plan doesn’t cover all possible

sources of water. If your source is not covered (e.g.: sourced from another RMP operator or

water where additional treatment is applied by you), you will have to write your own water-

use plan and water-use criteria. You could use the checklist and the Water supporting

system to help you do this. You will need to meet the water requirements in

Chapter C of the Animal Products Notice: Production, Supply and Processing

(www.mpi.govt.nz/dmsdocument/50182).

How to complete and register the Risk Management Programme for Micro Abattoirs Page xvi

How to Register the RMP

1.1 Complete the RMP template

You must complete all parts of the RMP template and write any additional procedures or

other documents that you need.

If changes have been made to the template

If your operations are not fully covered by this template, or you decide to deviate from the

requirements and procedures given in this template, you will need to modify this template

with additional information or write your own RMP. In most cases, these will need to be

evaluated by an MPI recognised RMP evaluator.

If you decide to modify the template after you have registered it, talk to your verifier first.

1.2 Complete the Application forms

Fill in both of these application forms:

• Application Form AP4: Registration of Risk Management

Programme (www.mpi.govt.nz/dmsdocument/71)

• Application Form AP49: Processing Categories Tables

(www.mpi.govt.nz/dmsdocument/4562)

1.3 Apply for Registration

To apply for registration of your RMP, send the following information to MPI Approvals

• completed RMP template, which is Part 1: Required Information and Part 2:

Supporting Systems.

– check you have added the name and date of issue for each document you have

created yourself to 1.7 RMP Document List,

• completed Application Form AP4: Registration of Risk Management Programme

– check you have included all additional documents required by the AP4 form,

• completed Application Form AP49: Processing Categories Tables

MPI may ask for clarification or further information on any part of the RMP. There may be an

additional assessment fee charged for the time of the MPI assessor so it is advisable to

complete the RMP template and application forms as best as you can. The RMP will be

registered once MPI is satisfied with the RMP and all fees are paid.

How to complete and register the Risk Management Programme for Micro Abattoirs Page xvii

1.4 Keeping the Registered RMP up-to-date

Updates to information held in the template can be made. Amendments to contact details

such as emails, phone numbers or postal addresses can be made by emailing the information

to be changed to approvals@mpi.govt.nz.

Amendments to other details such as the trading name and the name of the

day to day manager will be a minor amendment and an AP50: Registration of a

Minor Amendment (www.mpi.govt.nz/document-vault/4567) form must be

completed and emailed to [email protected].

When making any amendment to an RMP, you have to determine whether the amendment

is considered significant or minor. Detailed guidance on RMP amendments is given in the

RMP Manual. Appendix G of the manual provides examples of significant and minor

amendments. You can also consult your RMP verifier when deciding whether an amendment

is significant or minor.

Other minor amendments may require notification to MPI (you will need to submit an AP50:

Registration of a Minor Amendment (www.mpi.govt.nz/document-vault/4567) form).

Significant amendments are to be submitted using the AP6: Risk Management

Programme Amendment Registration (www.mpi.govt.nz/dmsdocument/4573).

If the amendment relates to an activity outside the scope of the RMP

template, the amended RMP will require evaluation.

All amendments made to the RMP should be recorded in an Amendment

Register (www.mpi.govt.nz/dmsdocument/26566). A sample register is

included in this link to the RMP Operator Resource Toolkit.

Pages i to xvii are not part of the RMP and DO NOT need to be

submitted to MPI

The RMP starts on the next page, page 1

Risk Management Programme for Micro Abattoirs – Required Information Page 1

Risk Management Programme for Micro

Abattoirs

Part 1: Required Information

Please complete the tables as required.

1.1 Identifying Information

RMP ID

1.2 Day-to-day Manager

Name, position or

designation of the Day-to-day

Manager of the RMP

Email

In entering this email, I consent to being sent information and notifications electronically.

Mobile phone number

Risk Management Programme for Micro Abattoirs – Required Information Page 2

1.3 Operator Name, Business Address and Contact Details

NZBN

Full Legal Name

Trading Name, if any (if

different from legal name)

Physical address (for fixed

premises)

or

Main location address for

mobile premises)

Vehicle Registration

Number (for mobile

premises only)

Postal address including

postcode (if different from

the physical address)

Phone number

Mobile phone number

Email

Risk Management Programme for Micro Abattoirs – Required Information Page 3

1.4 Scope of the RMP

Type of premises

Type of premises covered by the RMP:

☐

Fixed premises

The layout and RMP physical boundaries of the

fixed premises are shown on the attached site

plan.

☐

Mobile premises

The layout of the mobile premises (i.e. the

vehicle) is shown on the attached site plan.

This RMP applies to the following animal species:

The species covered by the RMP:

☐

Cattle (excluding bobby calves)

☐

Buffalo

☐

Deer

☐

Sheep

☐

Pig

☐

Goat

☐

Alpaca

☐

Llama

☐

Horse

☐

Rabbit

☐

Emu

☐

Ostrich

Risk Management Programme for Micro Abattoirs – Required Information Page 4

Processes

The RMP covers the following processes

(Tick all applicable processes)

☐

Receiving of live animals

☐

Ante-mortem examination

☐

Slaughter

☐

Post-mortem examination

☐

Dressing

☐

Collection of offal and co-products

☐

Cooling of carcasses and offal

Risk Management Programme for Micro Abattoirs – Required Information Page 5

1.5 Other Activities, Risk-based Measures or Operators

These activities occur within the physical or mobile boundaries of the RMP, but are excluded from the RMP and:

• they are covered under a different risk-based measure (e.g: an RMP, a Regulated Control Scheme, a Food Control Plan, a National Programme or under the Wine Act 2003);

or

• they are not covered under a different risk-based measure; or

• they are carried out by a different operator.

Procedures are in place for ensuring that these products are not a source of contamination to any products that are stored in the premises.

Activity

Covered under a Risk-Based

Measure

(if Yes, include which one and ID)

Control Measures

Responsibility

(Name or job title, include name of

different operator if applicable)

Transport of carcasses

Consider safe approaches to loading carcasses on to

transport to ensure this process doesn’t interfere with

food safety.

Risk Management Programme for Micro Abattoirs – Required Information Page 6

1.6 External Verification

(1) I give my contracted risk management programme verifier access to any and all

places, things and information that may reasonably be needed to complete the

verification, including:

a) freedom to access premises, places, or facilities covered by a risk

management programme; and

b) access to documents, records, and information that relate to a risk

management programme; and

c) access to things (including containers and packages) that are used in

connection with processing animal material, animal products, non-animal

product foods and non-food animal products under a risk management

programme; and

d) access to animal material, animal product, equipment, packages, containers,

and other associated things used in processing animal material, animal

product, non-animal product foods, and non-food animal products under a

risk management programme (noting that the verifier may identify and mark

any of those things); and

e) such freedom to examine and take samples (for the purpose of analysis or

retention) of animal material, animal product, non-animal product foods,

non-food animal products, or any other outputs, substance, or associated

thing which has been, is, or may be used in contact with, or in the vicinity of

animal material, animal product, non-animal product foods, or non-food

animal products being produced or processed under a risk management

programme.

(2) I will provide my contracted risk management programme verifier with any

reasonable assistance requested.

(3) By way of explanation, in the case of a significant risk to the fitness for intended

purpose of animal product or suitability of animal material for processing, a

recognised risk management programme verifier may recommend to an Animal

Product Officer that the officer exercises their powers of interruption of operations

under section 89 of the APA which (in

the case only of the powers under section 89(b)

and (c)) may be exercised by the Animal Product Officer over the phone if he or she

considers that appropriate.

☐

A letter (e.g. hardcopy or electronic confirmation such as an email) has been

received from the verification agency confirming they will verify the risk

management programme at all sites covered by this risk management programme.

Risk Management Programme for Micro Abattoirs – Required Information Page 7

1.7 RMP Document List

Table 1: Documents from the RMP template

The date authorised will be the same as the date Section 1.9 is signed.

Title Date Authorised

Part 1: Required Information

Part 2: Supporting Systems

Part 3: Regulatory Limits and Hazard Analysis

Risk Management Programme for Micro Abattoirs – Required Information Page 8

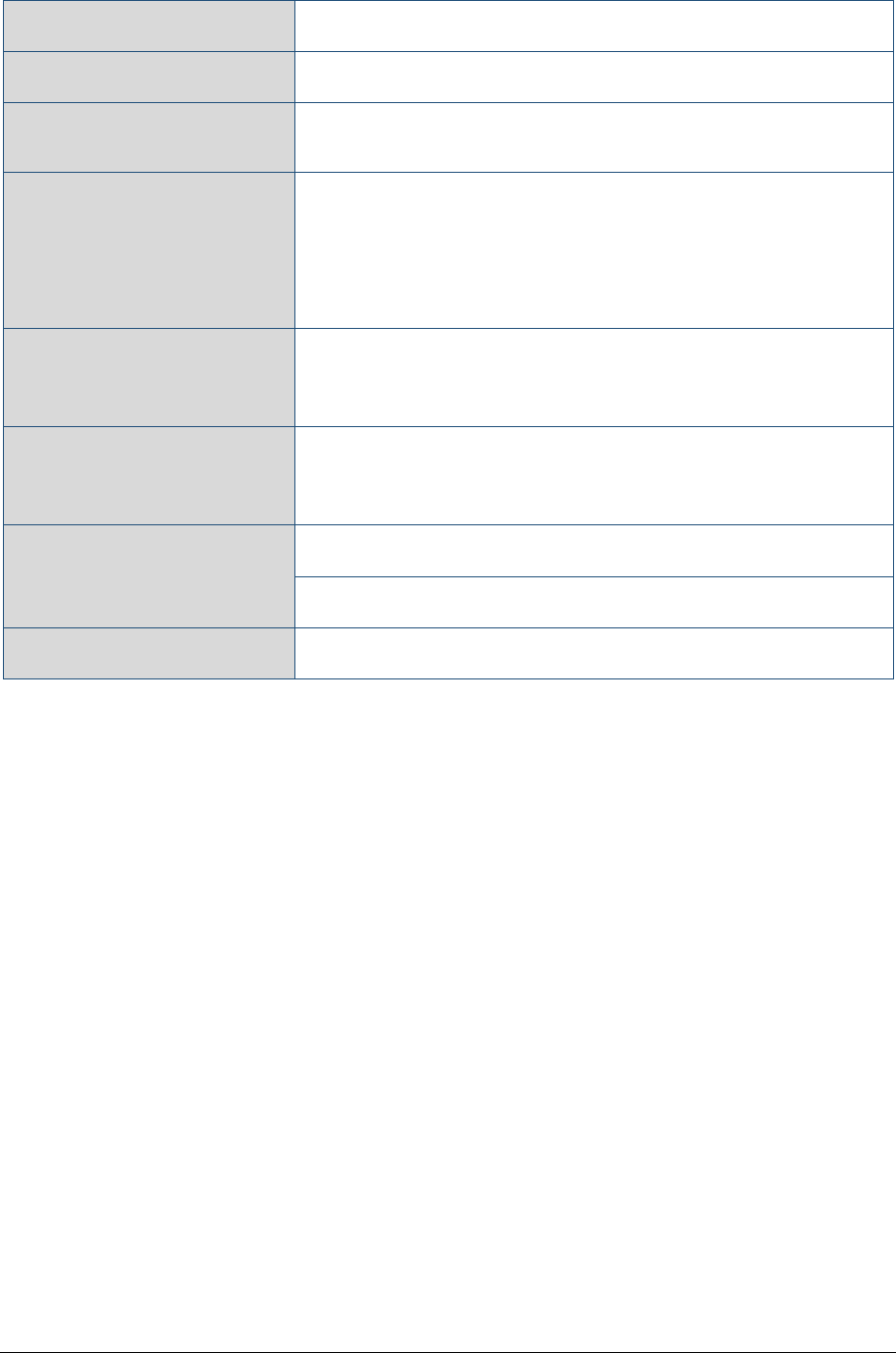

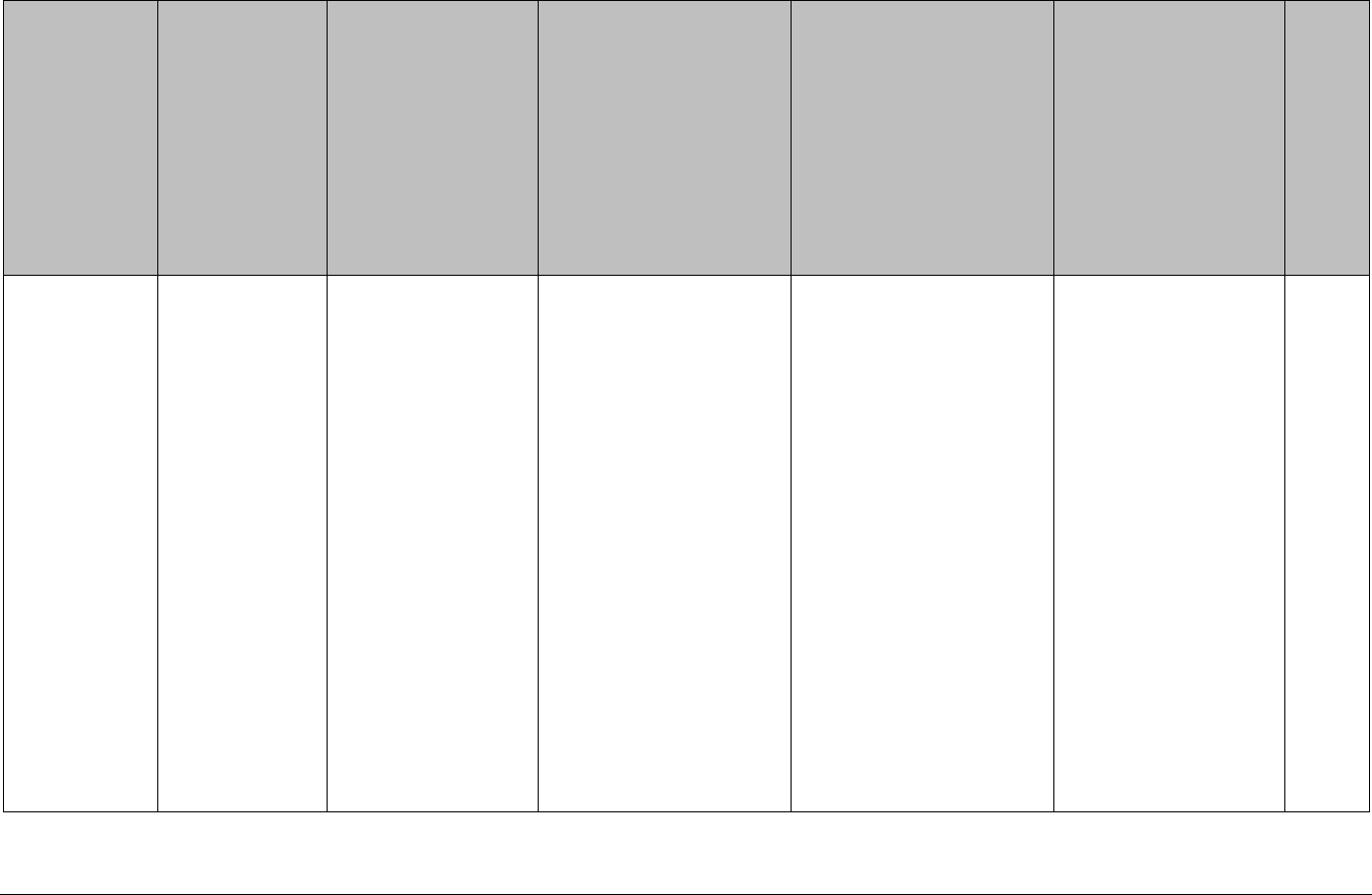

Table 2: Additional documents written by the operator

These additional documents include: procedures; programmes; site plan; list of nominated

persons; water checklist; amendment record etc.

These documents must be authorised by the day-to-day manager or a nominated person

and may be authorised individually and separately to the documents from the RMP template

(Table 1).

Each document must be re-authorised each time it is updated.

Updating a document you have written yourself might be a minor or significant amendment.

Title Authorisation

Name:

Date:

Name:

Date:

Name:

Date:

Name:

Date:

Name:

Date:

Name:

Date:

Name:

Date:

Name:

Date:

Name:

Date:

Name:

Date:

Risk Management Programme for Micro Abattoirs – Required Information Page 9

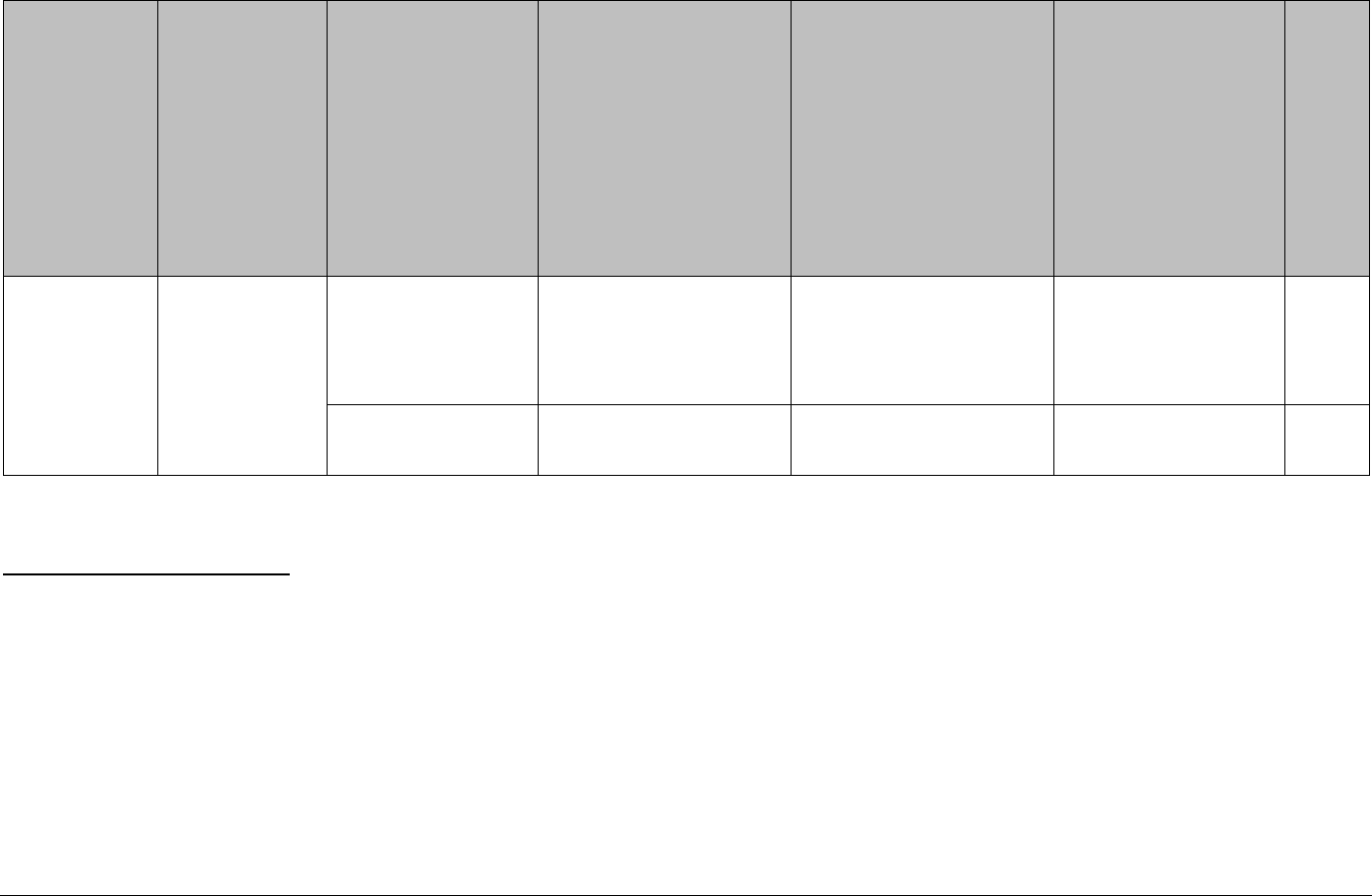

Title Authorisation

Name:

Date:

Name:

Date:

Name:

Date:

Name:

Date:

Name:

Date:

Name:

Date:

Name:

Date:

Name:

Date:

Name:

Date:

Name:

Date:

Name:

Date:

Name:

Date:

Risk Management Programme for Micro Abattoirs – Required Information Page 10

1.8 Authorisation of the RMP

I confirm that:

☐

All of the documents listed in Section 1.7 are appropriate for my operation.

☐

All building, facilities and equipment necessary to implement the RMP are

available and ready to operate.

☐

The RMP, including all relevant legislation incorporated into the RMP, will be

implemented as written.

☐

☐

The documents from the RMP template, including all Supporting Systems have

been authorised by:

The day-to-day manager of the programme

or

A nominated person

Signature

Title:

_________________________________________________________________

Date

The RMP must be re-authorised (signed and dated) each time a minor or significant

amendment is made to the documents from the RMP template (i.e. section 1.7 Table 1).

Risk Management Programme for Micro Abattoirs – Supporting Systems Page 11

Part 2: Supporting Systems

A. Document Control and Record Keeping

Useful things to know

• To ensure all RMP documents are authorised, controlled, kept up-to-date, and

stored properly.

• To ensure records are generated and stored properly.

Rules you must follow

Document control

• Every document that forms part of this RMP is dated and authorised (see RMP

Document List (Tables 1 & 2) by:

− the Day-to-day manager; or

− a nominated person.

• All current RMP documents and their date of authorisation are listed in the RMP

Document List (Tables 1 & 2).

• All RMP documents are:

− able to be clearly read; and

− indicate their version or date of authorisation.

• Details of all amendments to the RMP, including minor and significant

amendments, are recorded in an Amendment Register. (The RMP Manual

(www.mpi.govt.nz/dmsdocument/183) has guidance on determining if an

amendment is minor or significant.)

• The most recent amendments made in a document are identified by highlighting

or marking the amended part(s).

• Current versions of RMP documents are readily available, in hard copy or

electronic form, to persons with key responsibilities in operating the RMP.

Record keeping

• A list of the nominated people (who can authorise documents, as per above

section) is kept.

• All records identified in the RMP are clear and readable.

• All paper and electronic RMP records (e.g. monitoring, corrective action,

verification and validation records) include:

− the date and, where appropriate, the time of the activity or observation;

− an accurate description of the results of the activity or observation; and

− the identity of the person(s) who performed the activity (i.e. initials or

signature of the person completing the record).

• Any alteration made to a record is made in a way that allows the original entry to

remain readable (i.e. erasures or the use of correction fluid or tape or other

material to cover the original entry is not allowed) and is initialled by the person

making the alteration.

Risk Management Programme for Micro Abattoirs – Supporting Systems Page 12

• The following records are kept for at least 4 years:

− a copy of every supplier statement received from suppliers;

− records that provide the following information for each mob of animals:

• date and time of arrival

• supplier (name in clear wording or in code)

• number of animals

• class of animals

• any marks, brands, or other distinguishing features on the animals, if

the holding facility contains animals from more than one supplier

• information to determine where the animals from the mob are being

held.

Accessibility and retention of all RMP documents and records, including archived

documents

• One copy of all RMP documents and all records, including those that are

obsolete/out-dated/previous versions, are:

− retained for 4 years, or for the duration of the shelf-life of the product

(whichever is longest); and

− stored in a location where they are protected from damage, deterioration or

loss.

• Any validation information is:

− kept for the life of the process or activity; or

− until the process is revalidated and new records are created (then the old

validation information is archived and retained for 4 years)

• All electronic RMP documents and records are backed up regularly.

• All RMP documents and records, including archived documents, are able to be

made available to the RMP verifier or any person authorised by MPI, within 2

working days of a request being made.

Amendments

• All amended parts of the RMP are replaced with the current versions without

unnecessary delay after authorisation.

• An amendment register, which includes the following information, is maintained

by the RMP operator:

− document and specific part being amended;

− details of amendment;

− reason for amendment;

− date of change; and

− person approving the amendment.

• Any alterations on records are made alongside the original entry and initialled by

the person altering the record.

Monitoring for Operator Verification

• Compliance with these procedures is checked at least ______________ by the

responsible person.

Risk Management Programme for Micro Abattoirs – Supporting Systems Page 13

Things to show your verifier

• Document list.

• List of nominated persons (if any)

• Obsolete documents and documents are filed.

• Records are complete and available upon request (e.g. In the RMP Operator

Resource Toolkit Amendment Register).

• Supporting System and process control records (including monitoring, corrective

action and verification records).

• Record forms.

• All records generated while operating the RMP.

Examples of these forms can be found in the RMP Operator Resource

Toolkit

Risk Management Programme for Micro Abattoirs – Supporting Systems Page 14

B. Personnel Health and Hygiene

Useful things to know

• To ensure that all personnel are medically fit to perform their duties, and that

they comply with good hygienic practices to prevent or minimise the

contamination of product.

• Personnel include all workers, staff, contractors providing services and visitors.

Rules you must follow

Induction and ongoing supervision of personnel

• New personnel are informed of their job description, health requirements, and

hygienic practices and procedures before starting work.

Health and sickness policy

• The Day-to-day Manager ensures that all personnel understand and comply with

the health and sickness requirements discussed in this section.

• All personnel (including visitors and contractors) are required to inform the Day-

to-day Manager or another responsible person if they are suffering from any of

the health conditions listed in Table B.1 below.

• Personnel suffering from a health condition or illness listed in Table B.1 should

not carry out tasks where animal products may be affected.

• There are procedures to deal with any event where animal products are

contaminated (e.g. blood or vomit on product). Refer to M. Non-conforming

Product and Recall and N. Corrective Action

Table B.1. Health conditions

Condition or illness

Diarrhoea or vomiting due to gastroenteritis or other infectious diseases

including norovirus and rotovirus.

(May also include illnesses involving E. coli, Salmonella spp., Shigella spp.,

Campylobacter, Yersinia, Cryptosporidium, Giardia, and Vibrio cholerae)

Acute respiratory infection

Hepatitis A

Skin infection (e.g. boils, sores, infected wounds, etc.)

Protective Clothing

• Ensure that protective clothing is visibly clean at the start of each day’s operation.

• Ensure protective clothing and footwear is:

− maintained in a hygienic condition;

−

made of readily cleanable materials;

Risk Management Programme for Micro Abattoirs – Supporting Systems Page 15

− cleaned or changed if it becomes a source of contamination during

processing; and

− stored in a manner that protects it from contamination.

• Ensure disposable or damaged protective clothing and footwear is:

− discarded after use, when damaged (e.g. torn), or if it cannot be effectively

cleaned when required during use; or

− repaired.

• Everyday clothes are not worn over protective clothing.

• Reusable aprons are cleaned and sanitised at least daily.

• Disposable aprons and gloves are discarded after use, or when torn, damaged or

contaminated.

• Waterproof protective clothing (e.g. aprons, gloves) is not worn outside

processing areas.

• Protective clothing is not worn in areas outside the premises where there is

potential for them to be exposed to contaminants.

Gloves

• If used, re-useable gloves are cleaned and sanitised periodically during the day’s

operations, and at the end of the day’s operation or shift using the appropriate

method below.

− Cut-resistant gloves are soaked in appropriate sanitiser overnight and rinse

with warm water prior to use; or

− Chain mesh gloves are hosed with high pressure hot water to remove visible

soil, soak in appropriate sanitiser (20-25%) for no less than 15 minutes, soak

in hot water for no less than 15 minutes, rinse with high pressure hot water,

and hang to dry.

Washing of hands and arms

• All personnel thoroughly wash hands and exposed parts of the arms with

approved liquid soap and water, and then dry them using disposable paper

towels (or a suitable alternative):

− after using the toilet;

− after handling or coming into contact with waste and contaminated surfaces

or material; and

− after contaminating the hand from coughing, sneezing or blowing the nose.

Note: If clean water is not readily available for hand washing in certain areas,

alternative options for sanitising personnel hands may be considered.

Jewellery and other personal items

• Personnel in processing areas are not permitted to wear watches, rings and

other jewellery except for plain wedding bands (e.g. no stone). Plain wedding

bands may be worn only when they cannot be easily dislodged, and they can be

effectively cleaned in the same manner as hands.

Risk Management Programme for Micro Abattoirs – Supporting Systems Page 16

• False eyelashes, false fingernails, nail polish and other nail art are not permitted

in processing areas, unless they can be worn under gloves (without piercing the

gloves).

• Devices (e.g. medic alerts) and cultural jewellery (e.g. taonga necklace, wedding

jewellery) may be worn in processing areas provided they cannot be easily

dislodged, and they are able to be securely worn under clothing or gloves.

• Personnel are not permitted to take personal items (e.g. cigarettes, small loose

items) into processing areas that may result in contamination of products and

processing areas.

Note: A processing area in this part means areas where materials and products

are exposed, or food contact surfaces may be contaminated.

Visitors and contractors

• All visitors and contractors are required to report to the responsible person on

arrival.

• Visitors and contractors who enter processing or storage areas are required to

confirm that to the best of their knowledge they have no medical condition that

may pose a risk to food safety. Records of this should be kept (e.g. signed

declaration or logbook).

• If a visitor or contractor is visibly ill, the responsible person can deny them access

to processing or storage areas.

• Prior to entering the processing or storage areas visitors and contractors should

wear clean protective clothing and footwear that are provided or approved by

the Day-to-day Manager.

• Where appropriate, visitors and contractors are supervised by assigned staff

while within the premises. The assigned staff are responsible for ensuring that

visitors and contractors follow hygienic practices and procedures.

Hygienic practices

• Personnel behave in a manner that prevents the contamination and deterioration

of product and the environment.

• Eating, drinking, smoking, vaping or spitting are not allowed inside the processing

areas.

Visitors and contractors

• Where appropriate, visitors and contractors are supervised by assigned staff

while within the premises.

Monitoring for Operator Verification

• Compliance with these procedures is checked at least ______________ by the

responsible person.

Risk Management Programme for Micro Abattoirs – Supporting Systems Page 17

Things to show your verifier

• A record of all employee illnesses and any medical certificates e.g. Staff Sickness

form.

• Completed register for injuries (or similar).

• Completed training records e.g. Personnel Training Form.

• Any problems detected and any corrective actions taken. Refer to N. Corrective

Action.

Examples of these forms can be found in the RMP Operator Resource

Toolkit

Risk Management Programme for Micro Abattoirs – Supporting Systems Page 18

C. Personnel Competencies and Training

Useful things to know

• To ensure that all personnel have the necessary knowledge, skills, and training to

perform their assigned tasks in a competent and hygienic manner, including

relevant experience and ongoing refresher training in hygienic slaughter and

dressing of animals.

• For additional useful information, refer to Operator Verification Guidance

(www.mpi.govt.nz/dmsdocument/40898)

Rules you must follow

Competencies of key RMP personnel

• All personnel (other than the Day-to-day Manager) who have been nominated to

authorise the documents that form this RMP are identified (either by position, or

by name and position).

• Personnel responsible for the following key tasks are identified (either by

position, or by name and position).

− process control,

− operator verification,

− corrective action,

− undertaking recalls,

− monitoring at Critical Control Points,

• Personnel performing key tasks have the following competencies:

− knowledge and skills in executing the particular task; and

− an overall understanding of the area they are working in.

• The skills or competencies are documented on the Personnel Training Form.

Day-to day Manager

• The Day-to-day Manager is responsible for:

− ensuring proper implementation of documented RMP programmes and

procedures, including monitoring of processes and taking corrective actions

for any non-compliances;

− keeping RMP documents up-to-date;

− verifying the effectiveness of the RMP;

− communicating with the RMP verifier, as needed; and

− ensuring all personnel are adequately trained.

• The Day-to-day Manager has a good understanding of the documented RMP,

including legal requirements and supporting systems.

• The Day-to-day Manager is identified (either by position, or by name and

position) in the RMP.

• The RMP is amended if the Day-to-day Manager changes. Refer to D. Operator

Verification.

Risk Management Programme for Micro Abattoirs – Supporting Systems Page 19

Induction and supervision

• New personnel are informed of the following before they start working:

− the company’s health and sickness requirements;

− hygienic practices;

− movement of personnel and materials;

− cleaning and sanitation;

− handling of chemicals;

− hygienic handling of materials and products; and

− operational procedures for their assigned tasks.

• Ongoing supervision and/or skills maintenance is provided to ensure that

personnel are adequately trained in their specific tasks, and in hygienic practices

and procedures.

• The training programme includes:

− identification of skills and competencies required for key roles;

− training schedules (including refresher training); and

− training records of personnel.

Visitors and contractors

• Visitors and contractors report to a responsible person on arrival at the premises

or mobile premise location. Where appropriate, visitors and contractors are

supervised by assigned staff while within the premises.

• It is the responsibility of the assigned staff to ensure that hygienic practices and

procedures are followed by the visitor or contractor.

• Visitors and contractors are not allowed to handle materials or product in

processing and packing areas unless they have complied with all hygiene

requirements for food handlers.

Monitoring for Operator Verification

• Compliance with these procedures is checked at least ______________ by the

responsible person.

Things to show your verifier

• Competencies identified for key roles e.g. job descriptions, training matrix

• Training and qualification certificates.

• Completed e.g. Training Programme

• Completed e.g. Personnel Training Form.

Examples of these forms can be found in the RMP Operator Resource Toolkit.

Risk Management Programme for Micro Abattoirs – Supporting Systems Page 20

D. Operator Verification

Useful things to know

• Operator verification is a system of internal checks that confirms the

effectiveness of the RMP by:

− checking procedures are being followed (as noted at the end of most

supporting systems)

− corrective actions and preventative actions are taken

− reporting requirements are met

− other operational requirements are met (i.e. notification, amendments)

− establishing frequencies for checks, what is being checked, how and by

whom

− ensuring checks (including periodic monitoring and internal audits) are done

at the required frequencies.

• For additional useful information, refer to Operator Verification Guidance

(www.mpi.govt.nz/dmsdocument/40898)

Rules you must follow

Operator verification

• The Day-to-day Manager ensures that the RMP is effective by making sure that

the following checks are done:

− all activities that contribute to operator verification are transparent and

traceable, and undertaken by suitably skilled persons nominated by the Day-

to-day Manager

− persons carrying out operator verification activities are (if possible)

independent of the process or operation monitoring and corrective action

activities being verified. They are familiar with the contents of the RMP,

including its expected outcomes.

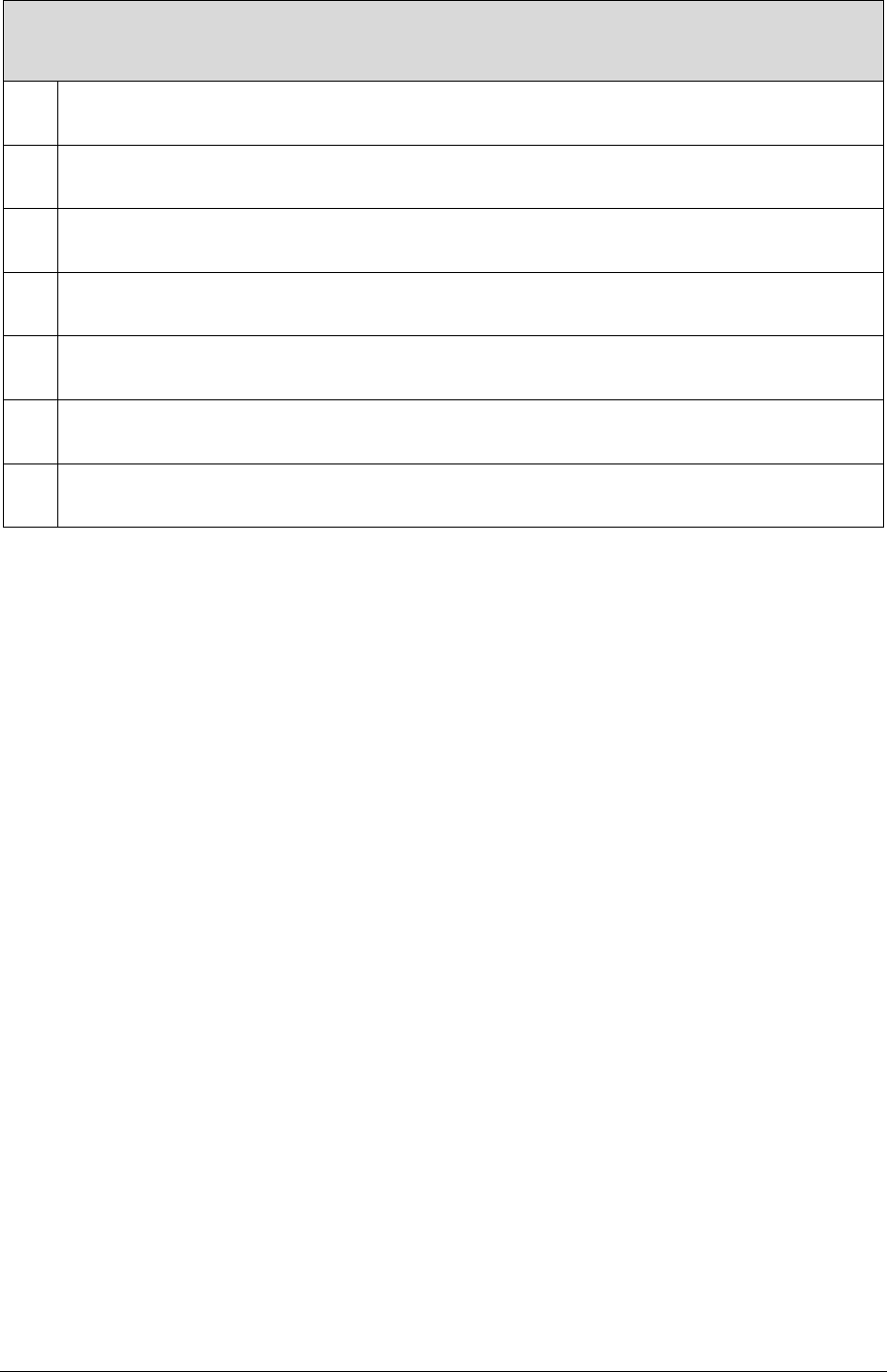

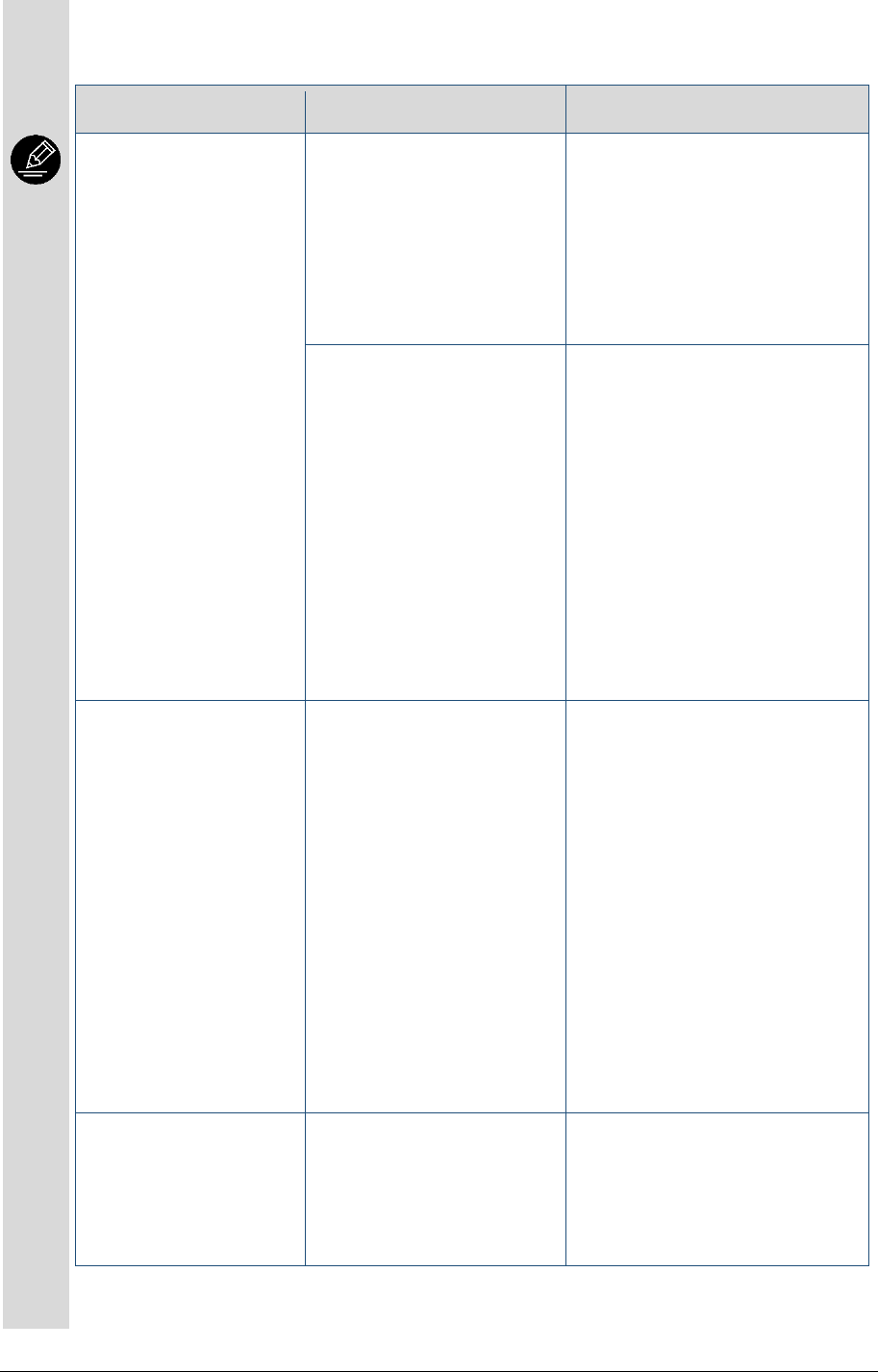

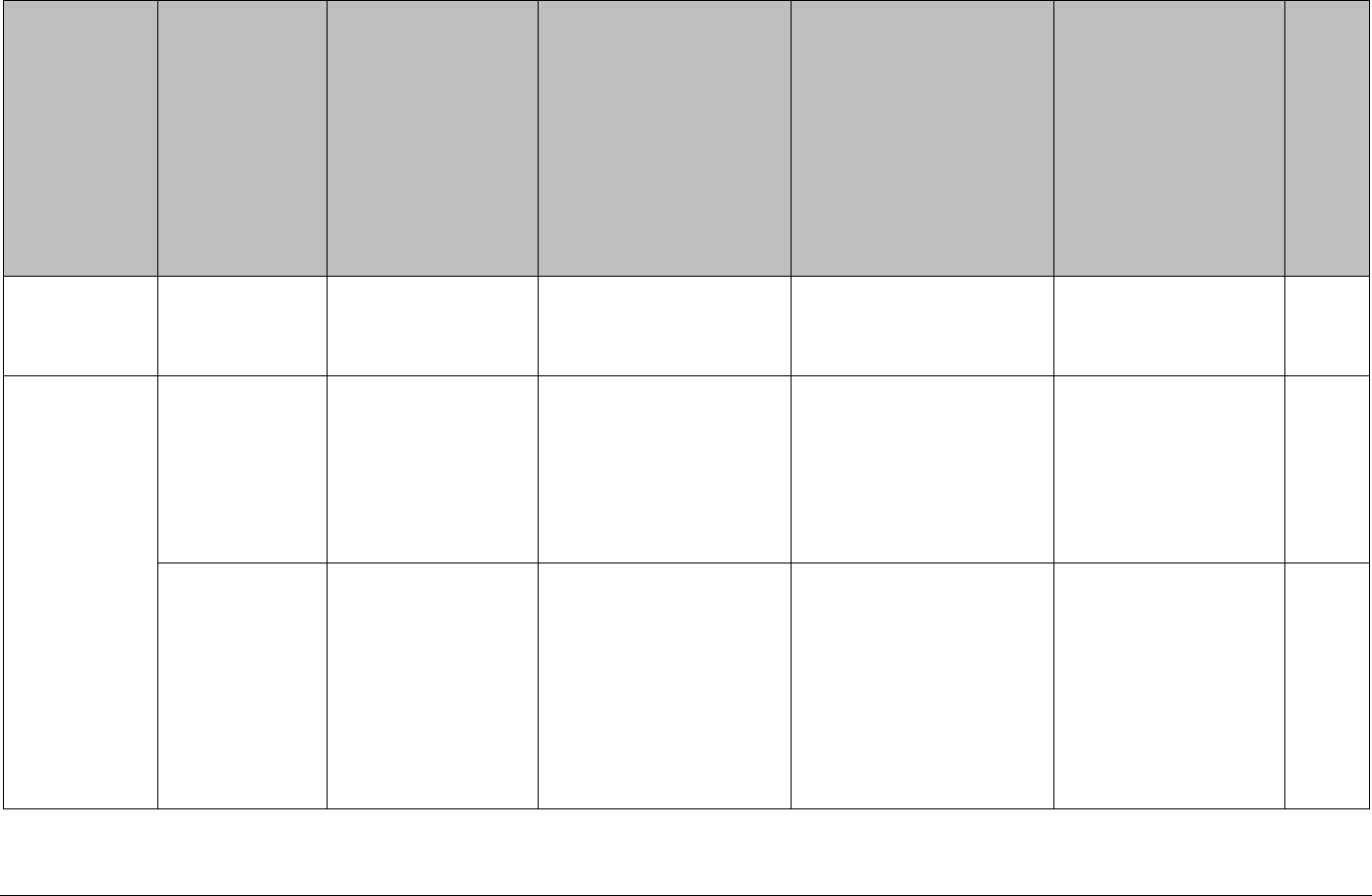

Table D.1: Operator verification activities and frequencies

Activity

Details

Frequency

Record checks

• Collect all records and check they

are complete, correctly filled out,

and that all results are acceptable or

the

appropriate corrective action has

been taken and documented.

• Review to identify any trends, new

hazards or recurring problems.

• When completed.

Personnel

supervision

• Ensure that all personnel are

following correct practices and

procedures.

• As required.

Risk Management Programme for Micro Abattoirs – Supporting Systems Page 21

Review of RMP

• Read through the RMP and amend it

where necessary.

• Perform a reality check to ensure

documented procedures are

followed.

• Test your recall plan by conducting

mock recalls for meat.

• Significant amendments will be

evaluated and registered.

• At least annually.

• When procedures

or premises

change.

• When RMP is not

working

effectively.

Internal audits

• Internal audits are an example of operator verification.

• Internal audits are about performing checks to ensure:

− the RMP is up to date and covers all activities.

− there are no uncontrolled food safety risks.

− the products are fit for intended purpose.

− staff know, understand and are correctly applying the procedures in the

RMP.

• The person responsible for undertaking internal audits has:

− a good understanding of the operations, processes and GOP covered by the

RMP; and

− a good understanding of the regulatory requirements.

• The person performing the internal audit does a reality check, which includes

observing staff, equipment and premises to make sure that:

− staff are following hygienic procedures and operating procedures;

− staff are following operating parameters (e.g.: temperatures); and

− hygienic status of the premises, internal and external environment and

equipment is maintained.

• A sample of records are checked during the internal audit to make sure the

correct things are being recorded.

• All findings from previous internal audits and external verification visits are

followed up to make sure they have been fixed.

• Any new issues found during the internal audit are identified and corrected.

Records are kept of this.

• When ongoing or recurring non-compliances occur, the following actions are

taken:

− investigate to determine possible causes of non-compliance;

− take appropriate corrective actions to regain control and prevent recurrence

of the problem;

− increase surveillance of the system; and

− review the RMP or the relevant Supporting Systems and make necessary

changes.

• Indications that the RMP or parts of it are not working effectively include:

− repeated non-compliance or out of specification product test results;

− customer complaints;

−

multiple or repeated issues raised by the RMP verifier; or

Risk Management Programme for Micro Abattoirs – Supporting Systems Page 22

− unacceptable outcomes from external verification visits.

RMP review

• The RMP is reviewed annually to check for any significant changes, such as

changes to equipment, facilities, personnel positions, RMP verifier, etc.

Significant Amendments

• After any significant amendment to the RMP has come into effect, all parts of the

RMP that may be affected by the amendment are checked to ensure they are still

effective and properly implemented.

HACCP plan review

• The HACCP plan is reviewed annually to check for any changes (e.g. to process

flow, inputs or outputs, new hazards, etc.).

Recording issues and findings

• The completed audits are recorded e.g. in the Annual Internal Audit Check

Sheets.

• Issues or findings requiring action and corrective action taken, are recorded e.g.

in the Corrective Action Register.

Notification

• The Day-to-day Manager will send an email to Food.Compliance@mpi.govt.nz

and their RMP verifier notifying of any product that is recalled because it is not or

may not be fit for its intended purpose.

letter to the Manager, Approvals Operations, MPI, PO Box 2526, Wellington 6140

notifying of any (it is recommended to inform your RMP verifier):

− change to the name, position or designation of the Day-to-day Manager of

the RMP; and

− change in RMP verifier.

99 66 (for biological hazards only) notifying of any emerging, new or exotic

biological hazards or new chemical hazards that have been discovered.

• The Day-to-day Manager will contact the recognised RMP verification agency

without unnecessary delay on discovering:

− significant concerns about the fitness for intended purpose of any product;

− that the cumulative effect of minor amendments necessitates the

registration of a significant amendment to the RMP;

− that the RMP is no longer effective;

− that the premises are no longer suitable for their use;

− that anything within the physical boundaries of the RMP is used for

additional purposes or by other operators, and the RMP has not adequately

considered relevant hazards or other risk factors;

−

merging two or more registered RMPs; or

Risk Management Programme for Micro Abattoirs – Supporting Systems Page 23

− splitting a registered RMP into two or more RMPs.

Who’s responsible?

Record the name or position of the person(s) responsible for undertaking/organising

Operator Verifications __________________________________________________

_________________________________________________________________

_________________________________________________________________

Things to show your verifier

• Any information or evidence relating to operator verification activities (e.g.

temperature readings).

• Internal audit documentation.

• RMP verifier audit reports.

• Completed e.g. Annual Internal Audit Check Sheets.

• Any problems detected and any corrective action taken. Refer to N. Corrective

Action.

• Copies of any emails or letters sent to MPI or the RMP verifying agency.

Examples of these forms can be found in the RMP Operator Resource Toolkit.

Risk Management Programme for Micro Abattoirs – Supporting Systems Page 24

E. Design, Construction and Maintenance of Buildings, Mobile

Premises, Facilities and Equipment

Useful things to know

• To ensure that all buildings, mobile premises, facilities and equipment are

designed, constructed, installed and operated in a manner that prevents or

minimises contamination of product, packaging, other inputs, equipment and the

processing environment.

• The requirements and procedures in this supporting system apply to both fixed

and mobile premises, unless specifically stated otherwise.

Rules you must follow

Buildings and facilities

• Internal structures of buildings, including floors, ceilings and walls, are designed

and constructed to:

− minimise contamination and cross-contamination of products;

− be durable and capable of withstanding repeated exposure to normal

cleaning and sanitising;

− resist corrosion;

− minimise the entrance and harbourage of pests;

− minimise the accumulation of condensation;

− minimise the entry of environmental contaminants; and

− be free from cracks and crevices that may harbour contaminants.

• Facilities are available and kept in a satisfactory condition for:

− hygienic processing, packing and storage of products;

− storage of chemicals, cleaning compounds and other materials;

− storage and reticulation of water;

− cleaning and sanitation of facilities and equipment;

− personnel hygiene (e.g. toilets, hand washing units, showering facilities,

storage lockers); and

− drainage and disposal of wastes.

• Facility and equipment layout (e.g. working space) allows for good hygienic

practices, access by personnel and effective cleaning.

• Essential services (e.g. lighting, ventilation, process gases) are sourced, used and

maintained in a way that enables effective operation.

• Lighting is sufficient to enable effective operations.

• All site and building entrances are clearly marked to deter unauthorised entry.

• Buildings and facilities are managed in a way that protects product, packaging

and other inputs from adulteration.

• Vehicle access and parking areas are designed and constructed to prevent

contamination of processing areas.

• Any glass, including light fixtures, is safety glass, or otherwise protected to

prevent contamination of the products, materials or packaging.

•

Windows are sealed.

Risk Management Programme for Micro Abattoirs – Supporting Systems Page 25

Mobile premises

• Mobile premises will follow the requirements for buildings (as appropriate).

• A mobile premises when operating its RMP, is located in an area that is:

− tidy and well maintained;

− adequately drained and not prone to flooding; and

− away from areas and activities that may impact on the hygienic operation of

the RMP and cause contamination of products and the processing

environment.

Animal holding facilities

• Animal holding facilities where animals are held prior to slaughter

need to comply with animal welfare requirements under the Animal

Welfare Act 1999

(www.legislation.govt.nz/act/public/1999/0142/latest/DLM49664),

and the Code of the Code of Welfare Commercial Slaughter 2018

(www. https://www.mpi.govt.nz/dmsdocument/46018)

• The facilities need to:

− effectively contain animals,

− facilitate ante-mortem examination,

− allow normal mobility and an easy flow of animals from the holding facility to

the slaughter facility, and

− for fixed premises, allow effective cleaning and effective drainage of water

and liquid waste.

• For fixed premises, separate holding facilities that meet the same requirements

given above, are provided for the holding of suspect animals and for the post-

mortem examination of animals found to be dead or dying.

Equipment

• Equipment that comes into contact with products is designed, constructed,

installed and operated in a manner that:

− ensures the effective performance of the intended task;

− facilitates cleaning and sanitising; and

− minimises contamination of the product.

• Suitable cleaning equipment (maintained in a hygienic condition) is available for

cleaning and sanitising of equipment and facilities. Refer to G. Cleaning and

Sanitation.

• Any equipment designed to cool products is operated within its design and

capacity, and consistently delivers the required temperature.

• Measuring equipment (whether stand alone or forming part of a piece of

equipment), has the accuracy, precision, and conditions of use appropriate to the

task performed. Refer to J. Calibration.

Risk Management Programme for Micro Abattoirs – Supporting Systems Page 26

Slaughter and dressing facilities

• Animal restraining and stunning equipment needs to comply

with the requirements of the Code of Welfare Commercial

Slaughter 2018 (www.mpi.govt.nz/dmsdocument/4601).

• Where a moving chain system is used, chain stopping devices

are provided to facilitate hygienic processing and carcass examination, and

ensure safe operations.

• Rails or other carcass elevating devices, or cradles are provided to ensure that

carcasses do not come into contact with contaminated equipment and surfaces

during processing.

• Facilities for washing waterproof protective clothing (e.g. boots, aprons, gloves)

are provided.

• Adequate space and facilities are provided for post-mortem examination so that

all parts of an animal can be examined effectively.

• Facilities or designated areas for retaining carcasses or carcass parts are

provided.

• Facilities are provided for secure holding and disposal of condemned material.

• Facilities and equipment used for condemned materials are properly identified.

• Chillers (and freezers, if available)

− are capable of reducing product temperatures to the required temperature

within the prescribed time, and maintain product temperatures at or below

the required temperature

− have the capacity appropriate for the volume of products likely to be

processed or held in the refrigeration facility at any one time; and

− are fitted with a temperature measuring device located where accurate air

temperature readings can be made (e.g. warmest location of the

refrigeration unit) and which can be monitored by the operator.

Repairs and maintenance

• Alterations, repairs and maintenance are done when necessary to ensure that

facilities and equipment are in a suitable condition.

• Processing stops if the facilities and equipment are in a condition that will affect

the product and make it not suitable for its intended use.

• Procedures set out:

− which areas and equipment are regularly checked for any issues that could

lead to damage or deterioration of product or packaging, and when or how

often checking is done;

− any other checking or inspection for maintenance that must be done;

− how assessment of the impact that maintenance work will have on

processing is done; and

− what corrective actions must be taken if product or packaging is affected by

maintenance.

• All alterations, repairs and maintenance work on facilities and equipment

(including refrigeration and freezing units) are done in a manner that minimises

Risk Management Programme for Micro Abattoirs – Supporting Systems Page 27

the exposure of product or packaging to hazards introduced by this work.

Corrective actions are taken if needed. Refer to N. Corrective Action.

• If any maintenance activity affects the suitability for intended use of the product,

then action is taken to stop more product being affected, including (if required)

stopping processing.

• Before use of facilities and equipment, a suitably skilled person checks that:

− maintenance is sufficiently complete so that when processing re-starts,

product will not be adversely affected; and

− areas and surfaces have been appropriately cleaned and, where appropriate,

sanitised; and

− if processing had stopped during the work, the area has been returned to a

suitable state for processing to re-start.

Changes

• MPI will be notified if there are plans to make major alterations to facilities or

equipment which may impact on the product(s) (this can be a significant

amendment to the RMP).

Refrigerated and frozen facilities and equipment

• Refrigerated and frozen facilities are designed, constructed and equipped to

ensure that the specified preservation temperatures are maintained throughout

storage.

• If installed, equipment for the control and accurate monitoring of temperatures

and any other required refrigeration or frozen parameters (e.g. humidity, air-

flow, etc.) are operated at an appropriate frequency, at all times that

refrigeration and frozen facilities are in use.

• Temperature measuring devices are located to measure the internal temperature

of the storage facility at the warmest point and are calibrated.

Note: Temperature measuring devices for critical measurements should be

calibrated at a frequency necessary for maintaining its required accuracy.

Operators should refer to the equipment supplier’s recommendation for guidance.

Recording issues and findings

• Issues or findings requiring action and the corrective actions that are taken are

recorded e.g. in the Repairs and Maintenance Register.

Monitoring for Operator Verification

• Compliance with these procedures is checked at least ______________ by the

responsible person.

Risk Management Programme for Micro Abattoirs – Supporting Systems Page 28

Things to show your verifier

• Completed e.g. Repairs and Maintenance Register, Maintenance Schedule,

Maintenance Form.

• Any equipment specifications, manufacturers’ or suppliers’ instructions (e.g. any

specifications or manuals related to refrigeration units).

• Any building reports.

• Any problems detected and any corrective action taken. Refer to N. Corrective

Action.

• Calibration records.

Examples of these forms can be found in the RMP Operator Resource

Toolkit.

Risk Management Programme for Micro Abattoirs – Supporting Systems Page 29

F. Water

Useful things to know

• To ensure that water is fit for its intended purpose at the point of use and

maintains the fitness for intended purpose of product.

• Where the water used can’t affect the animal products, this Water Supporting

System doesn’t apply (e.g. if water used for toilets is from a separate source).

• The requirements and procedures in this supporting system apply to both fixed

and mobile premises, unless specifically stated otherwise.

Rules you must follow

Water supply

• The source of water used within the premises is (tick all applicable):

☐ town supply water (a reticulated water supply that provides drinking

water to the public; no further treatment may be applied by the RMP

operator)

☐ own-source water (water other than town-supply water, or reused or

recovered water; e.g. water sourced from a bore, river, stream, roof; water

sourced from another RMP operator; water where additional treatment is

applied by this operator)

☐ reused or recovered water

Water use

• Water is used for:

− cleaning of facilities and equipment;

− personal hygiene activities;

− production of steam;

− use in washing equipment; and

−

other operational activities where water comes into direct or indirect contact

with any product.

Design and management of reticulation system

• The on-site water reticulation system is designed, installed and operated in a

manner that ensure water is delivered for the purpose for which it is intended;

and:

− minimises dead ends and backflow; and

− prevents the contamination of water and unintentional mixing between

water intended for different purposes.

• Water lines, including flexible hoses, in processing areas that contain water of

different standards (such as water that is unsuitable for direct or indirect contact

with animal material or animal product) must be labelled or otherwise identified.

• Water pipes, storage tanks and other parts of the reticulation system are

maintained in good condition.

Risk Management Programme for Micro Abattoirs – Supporting Systems Page 30

• The reticulation system is flushed (i.e. taps are opened at point-of-use to allow a

significant flow of water to occur) when water is not used for an extended period

and after any repairs to the system, to ensure that stagnant water, rust, scale or

other material is flushed out of the system.

Standard requirements for all water

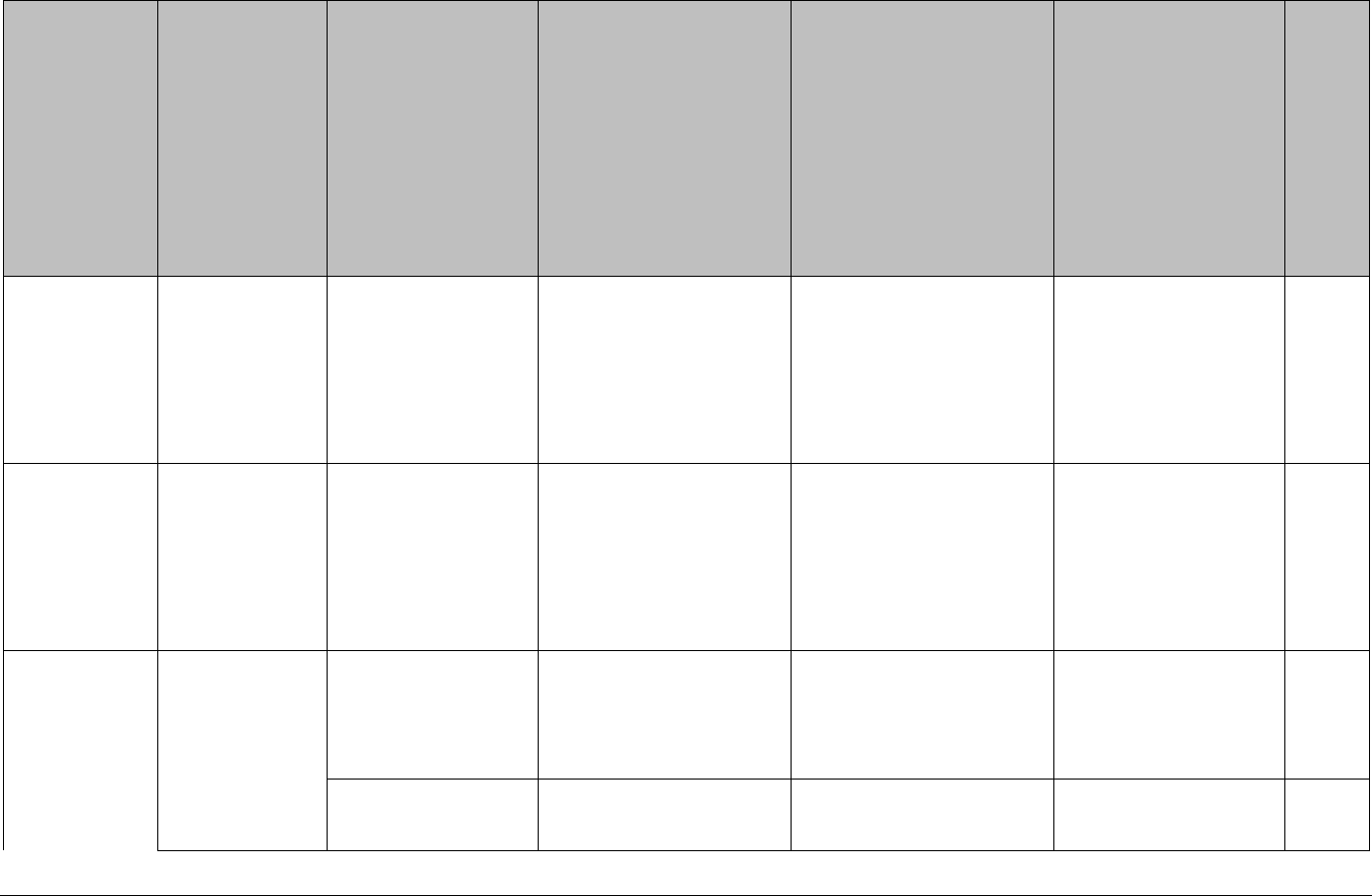

Table F.1: Standard requirements for all water

Measurement Criteria

E. coli

Not Detected per 100 ml

Turbidity